Scratch Dark Matter Driftship Original Design / Scratch Built

Scratch - Dark Matter Driftship {Scratch}

Contributed by Geof Givens

| Manufacturer: | Scratch |

Brief:

This is a transgalactic driftship employing unique dual dark matter ramjets for

high-speed travel to the edges of the charted universe. The ship carries a

scientific crew of up to 74 humans. Its primary mission is exploration and

astrobiologic sample collection. This is my first scratch rocket. It is a

single stage, minimum diameter futuristic tube fin rocket with parachute

recovery. It is designed for single use 24mm D and E engines. With an adaptor,

it can fly on 18mm motors. Construction is fairly challenging, especially the

cutting and joining of the elegantly curved tube fin assembly. For a fair

price, I can put together a kit with detailed instructions and photos. If you

prefer, I can send only a parts list with the instructions. Email me for

details. Below is a short description of how construction proceeded.

Construction:

The materials used are shown in the first photo. The rib fins are made from

1/16" basswood, and the fin tube was a heavy-duty variety. These and my

other parts were supplied from Aerospace Specialty Products. I was impressed by

the quality of the products they sent.

Construction began with the engine clip and thrust ring assembly, designed to accommodate both D and E motors with a removable spacer. I also made an optional 18mm motor adaptor so I don't lose this rocket on the first flight! A Kevlar® thread around the thrust ring was attached to elastic (just below the top lip of the body tube), with the parachute and nose cone attached to the elastic. The total Kevlar®/elastic shock cord length was about 3 feet.

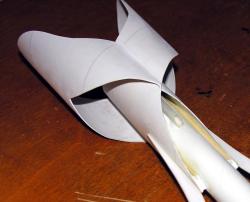

Next

came the cutting of the tube fins. Slow careful work was necessary to get good

edges and a perfect fit. See the photo of the fins before they were joined.

Contoured fin mounts were built and glued to the body tube, and the fin

assembly was glued to these. There is a photo of the tail portion of the rocket

after the fin assembly was attached. This also shows the placement of the

launch lug.

Next

came the cutting of the tube fins. Slow careful work was necessary to get good

edges and a perfect fit. See the photo of the fins before they were joined.

Contoured fin mounts were built and glued to the body tube, and the fin

assembly was glued to these. There is a photo of the tail portion of the rocket

after the fin assembly was attached. This also shows the placement of the

launch lug.

As I worked, I filleted all joints (inside and outside the tubes), and sealed and sanded all parts (basswood, nose cone, fillets, tube spirals (inside and outside fins), etc. The rocket was finished in gloss black, metallic copper, and a speckling of transparent cherry red, with two coats of clear gloss over the top.

Swing

testing the model with a D motor showed it to be perfectly stable, assuming you

want it to fly backwards! About 5/8 ounce of nose weight fixed this problem,

yielding a stable rocket weighing 3 ounces empty.

Swing

testing the model with a D motor showed it to be perfectly stable, assuming you

want it to fly backwards! About 5/8 ounce of nose weight fixed this problem,

yielding a stable rocket weighing 3 ounces empty.

Simulations suggest that a 3-5 second ejection delay should be about right for C-E motors. This delay, and the max altitude, are very hard to guess or simulate in advance since the design is unusual and its drag is unknown.

Flight:

The first launches were at 5000 feet altitude on a beautiful sunny Colorado

morning with zero wind. The first flight was straight and slow to about 350

feet, with a slight twist, on a C6-3 motor. Ejection was early, before apogee,

but the rocket recovered perfectly. The second flight on a D12-3 suffered from

rod whip, and the rocket buzzed around unstably until ejection and recovery

from about 50 feet. After cleaning and straightening the launch rod, we fired

again with another D12-3. The launch was fast and straight to perhaps 800 feet,

again with a slight twist. The parachute ejected while the rocket was still

coasting up. Unfortunately, a shroud line snagged around the parachute,

yielding tail-first lawn-dart recovery. This was worrisome because the tube

fins extend below the tail of the rocket and I had been worried from the start

about the strength of the tubes in a tail-first crash. Thanks to the quality

tube provided by ASP and my solid finishing, the fins survived with only a

small ripple in one which is hardly noticeable. Inspection showed that the

recovery system was fine, and it had simply been extremely unlucky that the

shroud line had tangled. The rocket is ready for its next flight without

repair. I think D12-5 should be a better engine for the next flights.

Summary:

This was a really fun project for my first scratch rocket. I had built a

conceptual model with notebook paper and tape first. I made some changes during

construction of the real model including the fin mounts to offset the fin

assembly from the body tube, the pointy leading edge of the fin tubes, and the

shape and joining-points of the rib fins. I'm pretty happy with the final

result although I'm not sure I'll ever get up the courage to try an E motor in

it.

Other:

Cutting and joining the curved fins made from the heavy-duty tube is quite

challenging. I recommend working very slowly, and anticipating about 4 passes

along the cutting line with a hobby knife. The first pass should be quite light

pressure...just enough to cut through the outermost layer of paper on the tube

to provide guidance for subsequent passes with the knife.

Sponsored Ads

|

|