Descon Python 4 Original Design / Scratch Built

Scratch - Python 4 {Scratch}

Contributed by Drake "Doc" Damerau

| Manufacturer: | Scratch |

Python 4

"The rocket that can't fly" . . . But does!

by Drake "Doc" Damerau

by Drake "Doc" Damerau

The Python 4 is an advanced fire and forget Air to Air missile with a fragmentation warhead used in the Israeli Air Force. The forward control fins set this apart from other weapons. They enable the missile to turn sharply in flight.

Since DESCON is a design contest, I decided to actually design something, rather than just build a rocket. This model is actually a prototype of a much larger one I am building. For this prototype, none of the dimensions were measured for scale. I just kind of eyeballed it, and sized things to fit what I had laying around. The goal was just to see if the idea worked. If it did, it would be an entirely new concept in rocketry.

Components

- 1 - 4" 24mm MMT

- 1 - 18" 1.6" tube

- 1 - 8.5" 1.6" tube

- 1 - Coupler

- 1 - Big Bertha nose cone

- 4 - 1 7/8" x 1/16" hardwood dowels

- 1 - shock cord

- 1 - 24" chute

- 2 - CR's

- 2 - sheets 3/32" balsa

- 1 - sheet 1/8" balsa

Forward fins

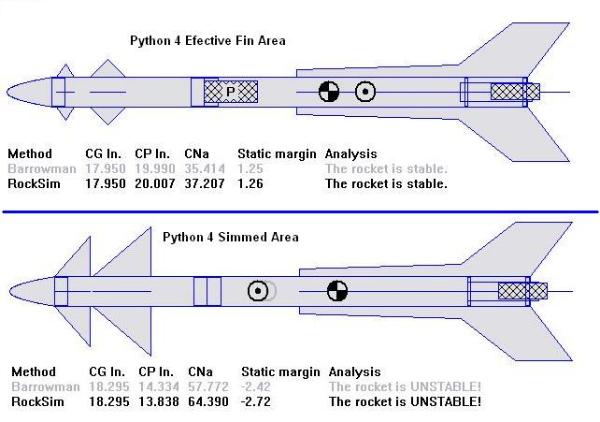

This is the tricky part. These fins must pivot with no effort or binding. According to Rocksim, this design is nearly 3 calibers unstable. The picture shows how Rock Sim sees the rocket with both the effective fin area and the fin area if the fins were glued on.

The reason this design works is that because they are allowed to move. Thus, they have little effect on the CP of the rocket because any force on the forward fins is dissipated by the fins moving. The total fin area forward of the pivot points, (times 2) is the surface area used in calculating the effective forward fin area. Because of the effective small canard area, no weight was needed in the nose. This concept opens up a whole new realm of possibilities for model rockets.

It's important to note that the pivot point must be as far forward as possible. The further forward the pivot point, the smaller the effective fin area will be.

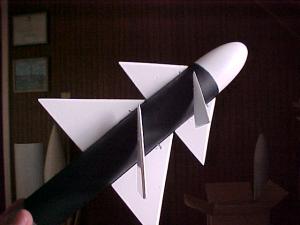

I used the thicker balsa here so that the dowels had more material to "bite", making the joints stronger. There is no good way to orientate the grain here. Because they are not glued to the body, the fins will be weak in any grain orientation. You can see in the pictures that I orientated the grain horizontally. I stiffened them up with CA to make them stronger.

The first thing that is done is drilling holes in the forward section to accommodate the dowel. You need to make sure that the holes for the dowels are square with the body. This ensures that the fins will pivot squarely. I did this by wrapping a piece of paper squarely around the body and drawing a line. Then just mark the line at 180 from each other. The other important thing here is that one set of holes is slightly higher than the other. This ensures room for the dowels to cross each other on the inside of the tube. The holes need to be coated with CA to make them clean and strong. You can glue the dowel to one fin and let it dry. The second fin needs to be glued on after the dowel is placed through the holes. DO NOT use to much glue. If you glue the dowel to the tube it won't work. Do the forward most fins first, than the other set. Once the forward fins are in place, the nose cone is glued into place. To get the forward fins as far forward as possible, I cut most of the nose cone base off to make room.

Aft Section

Aft Section

The motor assembly and the aft fins were typical of any rocket. The fins were made in two pieces and glued while lying flat on a table. The picture shows the direction of the grain. I chose not to install a motor hook to facilitate various engines.

Recovery

A shock cord was glued to the coupler in the forward section using the Estes technique. Another shock cord was glued to the body using the same technique. The two cords were tied in the middle and a 24" chute was attached.

Finishing

Finishing

The hardest part about painting this rocket was keeping a good finish on the body while the fins were attached. Care should be taken here if you attach your fins before painting. To avoid getting paint on the dowels and effectively gluing them in place, I wrapped waxed dental floss around the dowels. I did this after masking the fins. The loose ends of the dental floss were taped down to keep them from getting in the way during painting.

Hind sight is 20/20 here. Not knowing if it would even work, I decided to build and launch it before finishing it. Painting the fins before assembly would have made for both easier finishing and a better looking rocket. If you decide to paint the fins before gluing them to the dowels, make sure you leave some bare wood for the glue to adhere to.

I painted the forward section with a flat black finish. This would allow a less than perfect finish and hide most of the scratches caused by the fin movements.

I used Pactra Trim Tape for the stripes. I also used it on the fins to simulate a multi piece fin design.

Flight

Flight

I decided to try to fly it before finishing it. This way, if it was a disaster it would have wasted too much time on it. I didn't even have primer on it. I was going to launch this with a group of people, but than decided that if it didn't work, I'd look like a fool. So, I launched it alone. I launched it in my back yard. I let my wife watch because if it worked, I'd have a witness. If it didn't, I'd have someone to take me to the hospital. ;-)

First flight was on a C11-3. While I was setting up the pad and getting it ready for launch, I was thinking of the theory and kept going back and forth, it will work! No it won't. Yes it will! No it won't.

First flight was on a C11-3. While I was setting up the pad and getting it ready for launch, I was thinking of the theory and kept going back and forth, it will work! No it won't. Yes it will! No it won't.

It left the pad as true and straight as any rocket ever has. As it arched over and the chute came out, I started shouting "It worked! I knew it would!"

The second and third launches were during a TARC team practice launch. I also used it to discuss the CP of rockets. These too were on C's. The first flight this day went well, but the parachute stuck in the end of the tube and never deployed. The second attempt that day was a perfect flight with perfect recovery.

I have already begun a 4" version of this rocket. Precision roller bearings and other hardware are on order to take this bird to the next level. This one will include a boat tail and a more accurate nose cone.

Sponsored Ads

|

|

![Vintage Estes Viper #0820 Model Rocket [4*G-17.25] Vintage Estes Viper #0820 Model Rocket [4*G-17.25]](https://i.ebayimg.com/thumbs/images/g/Q7EAAOSwN1Nl1kDF/s-l225.jpg)