Scratch Mercury Transport 18mm Original Design / Scratch Built

Scratch - Mercury Transport 18mm {Scratch}

Contributed by Shane Tunkin

| Manufacturer: | Scratch |

Brief:

Brief:

After reading about the unique fin design of the Mercury Transport in an Apogee

Components newsletter, I thought this would be a great project and something to

get my teeth into, to become a better rocket builder. Using the

original

EMRR design brief I worked out that I could find or build all the parts

needed. My previous rocket projects had included some basic transitions and

also used RockSim files to upscale or downscale a design. So the Mercury

Transport took this all one step further. My project is very much 'McGuiver'

style - only one component of my Mercury Transport is designed for rocketry -

the rocket motor!

Construction:

- EMRR Mercury Transport RockSim file

- (8) 6 X 70 X 45mm balsa pieces for nosecone

- 1 sheet of 2.4mm balsa

- 200 X 4.2mm OD cardboard (pilfered from a roll of kitchen paper)

- 317.5 X 2.5mm OD cardboard (pilfered from a roll of black garbage bags)

- 3 cardboard centering rings and 2 transitions made from shoebox cardboard (Transitions were calculated using EMRR's Shroud Calculator)

- (4) 24 X 10 X 60mm balsa wood for engine mount

- 16cm of 1mm Copper wire for engine hook plus around 3 cm for nosecone to shock cord connection (Taken from an electrical transformer)

- 80 X 70mm cardboard for motor mount tube

- 1 black garbage bag

- 550mm elastic from sewing shop

- Selleys Tradesman's choice Aquadhere (Polyaliphatic wood glue)

- Wattyl Woodstop water based wood putty

- White Knight undercoat, colour and gloss paints.

I started the design by peeling back several layers of cardboard from the inner body tube (it was much too thick), then cutting the body tubes to length. Next, EMRR's Shroud calculator came in handy for designing two shrouds, which were around 12mm long. These were cut from shoebox cardboard, and glued and clamped. These were then slid down onto the inner tube, with the cones facing outwards.

Next I cut out two centering rings from the said shoebox, and these were also placed onto the inner tube and glued. (Transitions were slid into the centre to keep them out of the way)

The outer body tubes were then glued to the centering rings and carefully aligned to make sure they were parallel.

While this was left to dry, I started cutting out the fins and strakes, using the same two piece design as the original Mercury Transport.

The transitions were slid into place and glued. Then the upper and lower body tubes were masked, and the centre tube and transitions were filled and painted yellow.

While this was drying, I

started work on the nosecone. The NC can be made from any scrap balsa thats

lying around. Its a good idea to choose a glue which can be sanded easily. I

glued all the pieces together and placed some books on top and left it

overnight.

While this was drying, I

started work on the nosecone. The NC can be made from any scrap balsa thats

lying around. Its a good idea to choose a glue which can be sanded easily. I

glued all the pieces together and placed some books on top and left it

overnight.

The next day, using a Dremel I carved out the NC slowly, first making the shoulder to fit the upper body tube. After the NC is sanded into shape, you can add a coat or two of epoxy. This adds strength and helps the NC resist dents from prangs.

The motor mount tube was next. Thin cardboard often has a 'grain' it bends better in one direction than the other. With this in mind, I cut out a rectangle of cardboard so the 7cm length could be curled.

This can be soaked in water to help bending, then its just a matter of running a line of glue along the edge, wrapping it around a spent motor, and applying pressure to the joint until dry.

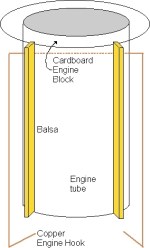

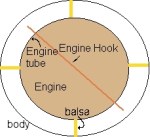

While its

drying, I cut out 4 small pieces of Balsa and these are used to centre the MMT

in the outer body tube. These are spaced evenly around the MMT and glued, then

a thin centering ring is cut out to block exhaust gases (See picture). A length

of copper wire is then cut. A spent engine is loaded into the MMT, until it

protrudes about 10mm. The wire is pushed through the MMT to act as a motor

block, and then its bent downwards to make two hooks to retain the motor (See

picture). This is then installed into the lower tube and glued in place.

While its

drying, I cut out 4 small pieces of Balsa and these are used to centre the MMT

in the outer body tube. These are spaced evenly around the MMT and glued, then

a thin centering ring is cut out to block exhaust gases (See picture). A length

of copper wire is then cut. A spent engine is loaded into the MMT, until it

protrudes about 10mm. The wire is pushed through the MMT to act as a motor

block, and then its bent downwards to make two hooks to retain the motor (See

picture). This is then installed into the lower tube and glued in place.

Before attaching the fins and strakes, I masked up the inner body tube. Then the nosecone and body were primed and painted, and finally a parachute was made from black garbage bag material and high tensile string. Packaging tape was used to hold the string onto the parachute. Lead weight was then added until the rocket passed the swing test. Lastly, the rocket was painted and the masking removed.

Flight:

Flight:

First flight was with a B6-4 for a nice slow flight, but because of the weight,

the 4 second delay was too long, and the parachute hardly opened before it hit

the ground. It received slight damage to the upper body tube, but nothing

major.

Second flight was with a C6-3, and I decided to remove some of the NC weight, which wasn't a good idea! Flight was unstable and not much higher than before.

Third flight went much better, but still it needs more altitude or a shorter delay.

Summary:

Overall this was a great project to build. It helped me with transition

building and also masking and finishing techniques. Weight was the biggest

issue, caused by too much glue on the centering rings, and also heavy cardboard

tubes. A D12 booster stage should help this in the future though.

Other Reviews

- Scratch Mercury Transport 18mm By Nick Esselman

( Contributed - by EMRR - 05/10/02) The Mercury Transport is a new design from Essence Aerospace Technologies (EAT). Its main purpose is to transport 4 passengers the 91.8 Million Kilometers to the planet Mercury for observation, study and experimentation in a high temperature, zero gravity, high sun-radiation environment. The Mercury Transport has fins that are suspended over the inner ...

Sponsored Ads

|

|