| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2017-04-17 |

| Manufacturer: | Apogee Components  |

Brief

Brief:

The Apogee Diamondback is an 18mm single stage streamer recovery model which stands just over 30” tall. While it does have three fins and a nosecone, this is not a typical 3FNC like you would find at the local superstore. This kit's pedigree is obviously from a stable which is rooted in mid-power rockets, as the kit features components that tend toward the mid-power standards. The unique multiple piece fin construction and overall dimension makes this a nice ‘fast’ looking rocket whether it is on the pad or on a shelf.

Construction:

The kit contains:

- 1 18mm Motor Mount Tube

- 2 29mm Body Tubes

- 1 Body Tube Coupler

- 1 13/18mm Motor Block

- 2 18-29mm Centering Rings

- 1 1/4" Launch Lug

- 1 29mm Plastic Ogive Nosecone

- 1 Laser-cut Balsa Fin Sheet

- 1 4" x 45" lg. Mylar Streamer

- 1 60" lg. 300# Kevlar® Shock Cord

- 1 Decal Sheet (Adhesive Back)

- 1 18mm x 2.75" lg. Engine Hook

- 1 Instruction Sheet A

- 1 Instruction Sheet B

- 1 Fin Marking Guide

This kits is labeled as a skill level 2 kit. In my opinion this is a slight overstatement as it requires only basic skills and would be a suitable rocket for anyone who has successfully built a rocket with balsa fin construction. However, in the world of EX2 kits, maybe this is indeed a fair assessment.

The instructions outline the build process very well with good pictures throughout. I did not follow the order explicitly, as noted below.

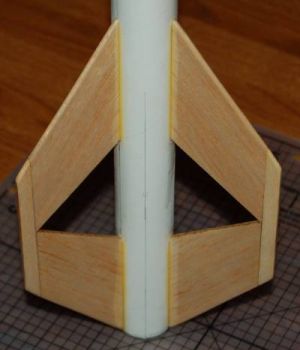

My first step was to prepare the fins for assembly and attachment to the rocket. These fins are made up of multiple segments. A total of 3 pieces are glued together prior to attaching to the body tube.

I assembled the fins per the directions and pressed under a weight to ensure they were flat. This is a mildly critical step as getting the proper alignment of the pieces will make sure the fins can attach to the body tube in a flat manner.

After the fins dry, go ahead and re-sand them flat in case there was any movement while drying. I chose to round the leading and trailing edges as well, even though you are not instructed to do so.

While the fins dry, it is a good time to glue the body tubes together, mark the body tube for fin placement, and construct the motor mount. The motor mount tube is marked per instructions as well as the body tube. Note that the kit includes an alternate revised fin alignment wrap, presumable due to an error in initial printing of the instructions. This is clearly noted in the included kit contents and should not pose an issue for anyone who looks through the kit contents.

While the fins dry, it is a good time to glue the body tubes together, mark the body tube for fin placement, and construct the motor mount. The motor mount tube is marked per instructions as well as the body tube. Note that the kit includes an alternate revised fin alignment wrap, presumable due to an error in initial printing of the instructions. This is clearly noted in the included kit contents and should not pose an issue for anyone who looks through the kit contents.

I enjoy flying 18mm reload motors on occasion and this rocket should prove to be a great match for the D13. People familiar with using an RMS 18mm casing in a standard rocket may already be aware of the need to shorten the engine hook at the front edge to clear the ejection charge cap. Details of this modification are not explained in the instructions, however, for people used to flying 18mm RMS, it is standard fare.

The hook can be trimmed with a file, tin snips, Dremel tool, etc. to get clearance for the red ejection charge container.

Following the modification to the engine hook, the motor mount can be assembled per the instructions and successfully flown with either black power 18mm motors, single use 18mm composite motors or 18mm reloadable motors.

Next, the fins can be attached. There is plenty of root chord for gluing the fins in place and the triangle opening helps sight the glue line easily when attaching them. I imagine this rocket would take a pretty good hit to the ground without breaking a fin free from the body tube. Carefully align the fins with the markings and attach the launch lug.

I chose to use sanding sealer to finish the fins prior to painting. Lastly I mounted the motor mount into the joined body tubes and the basic construction is complete.

I usually omit attaching the recovery device and nose cone prior to painting to facilitate ease of masking, etc.

Overall, this is a simple kit to execute and only requires a little patience with the fin construction. The motor hook modification is a typical modification to all 18mm kits for use with RMS hardware. The only omission, I would say, is the recommendation for rounding the fin edges, as this does increase the overall appearance of the rocket in my opinion.

Also, as noted in the flight report, it might be a good idea to leave the motor mount sticking out about 1/4" or so from the rear of the rocket as this facilitates an additional wrap of tape around the end of the motor/motor hook to reduce the chance of the motor kicking out during ejection. While this is not a requirement, it is a small variation which adds additional security for motor retention.

Finishing:

I chose to finish the Diamondback per the cover art using the supplied adhesive backed decals. I sanded the fins down with 120 grit sandpaper and the nose cone with 220 grit after cleaning the parting lines with an X-Acto knife. I used a tack cloth to rid the surfaces of dust.

The rocket was primed using brown Rustoleum primer and top coated with gloss white Rustoleum after a light sanding with 220 grit to knock down any fuzzies that occurred during priming.

The rocket was masked per the instructions using the specified cellophane tape and blue painters tape then painted with gloss black.

After a sufficient cure of a few days, I added the included decals and clear coated to reduce the chance of the decals pulling up over time.

This rocket looks good from a few feet away. The sticker decals are printed on a white background, not clear, which helps the yellow to look more uniform. However, this would make it impractical or at least a bit more difficult to do a color change and still use the decals. For instance, if one substituted silver for the white paint, the decals would have a white halo around them depending how closely they were trimmed. If a person were to try and go with an alternate color, I would suggest scanning the decals and printing on decal paper with no background, but the yellow will suffer.

One simple addition to help finishing would be a wrap printed in the instruction to help with the curve for the black to white transition as the method described in the instructions took me a few tries to understand and get right. This can however be easily done by the end user. This could also be done as an online PDF to save material costs.

Construction Rating: 4 out of 5

Flight:

Due to schedules and a club launch, I chose to launch the Diamondback for the first flights prior to completing the final paint. The nose cone was black and the body tube was white, but the transition and decals had yet to be applied. One thing worth noting is that no less than 10 club members commented about the "good looking rocket" with the "really cool fins." While I appreciated the comments about the innovative "scratch build", I did come clean and say that it was a kit available from Apogee.

I prepared the first flight using dog barf and a C6-5 as I did not have any B6-2s as recommended for the first flight. I did not friction fit the motor and only used the included motor hook for retention. The rocket left the pad quickly for an amazingly straight boost with practically no arc or rotation, ejected near apogee nose up, and settled in for a nice drift home.

For the second flight, I prepared an AeroTech D13-7W. As the day was turning questionable, I rushed flight prep a bit and did not use any friction fit on the reloadable motor casing and relied only on the supplied engine hook. Again, I added dog barf and headed to the launch pad.

Once my pad's turn to launch came up, I snapped a clear picture of the igniter spitting out of the back of the RMS motor with a failed ignition, again a likely result of my rush to get back to the flight line. After the pads cleared again, I went out and removed the motor from the rocket and reinstalled a new igniter. After installing the motor again, the rocket proceeded to launch very straight and true with deployment near apogee once again.

Recovery:

The rocket recovered well on the C6-5. It was a fairly windy day and as I launched at a club event, I had only minimal control over rod angle. The 4" x 48" streamer dropped the rocket fairly fast but it did drift with the wind a bit. The recovery was well within walking distance, however, it might have been farther than the typical schoolyard field. The motor was still in the rocket and the mylar streamer showed no noticeable damage.

The recovery on the D13-7W motor again drifted for a while. The rocket appeared to be falling slower. After a brief search I found the rocket, but the motor case was no longer inside. The motor must have kicked at ejection and fell to a different location. The lack of weight in the rear likely contributed to the slower fall. The mylar streamer was melted about 30% through where it attached to the shock cord. I suspect the motor had a fairly hefty ejection charge which likely contributed to the melting of the streamer or this could have been due to the handling of the rocket a second time at the launch pad during igniter replacement and a possible redistribution of the dog barf.

If I had it to do all over again, I would have prepared the second flight a little more slowly and ensured the motor was friction fit to the motor tube which may have saved the loss of the reload case. Allowing the motor tube to stick out 1/4 or 1/2" from the rear of the body tube would also have easily allowed a wrap or two of tape to help secure the engine hook to the motor as well.

Due to the long recovery time with evening approaching and loss of my only 18mm reload case, no more flights were available at the club that day.

Flight Rating: 4 out of 5

Summary:

This is a very slick design for an LPR and did garner many positive styling comments from fellow fliers. It performed well on both C and D motors and I believe from what I have seen that it would fly fine and be easily recovered on a B. I'll try that next launch.

The only changes I would recommend are listed above and are minor in the scheme of things and could well fall within flier preference instead of true changes to the build.

I believe a beginning rocketeer would be able to construct and fly this kit without any real problems.

Overall Rating: 4 out of 5

Other Reviews

- Apogee Components Diamondback By Chan Stevens (April 22, 2007)

Looks can be deceiving on this bird--it's a single-stage that could pass for a two-stager and is an 18mm bird that is begging to be promoted to 24mm. It's good to see Apogee add something to their modroc line, especially something with such cool looking fins. As is typical with Apogee, my kit arrived well packed a mere two days after placing the order along with a couple free goodies ...

|

|

Flights

Sponsored Ads

|

|