| Manufacturer: | Scratch |

|

Little Joe II Introduction and materials Construction Finishing and recovery system

|

|

Flying

Flying

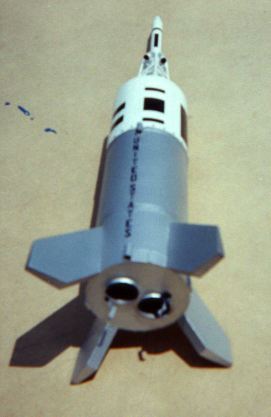

The model flies on (2) 24mm motors. Modeling on RockSim and AltiCalc showed the Estes D12-5 to be the motor of choice

for clustering. I have had good success with clustering Estes D engines. Altitude prediction with RockSim and AltiCalc

showed max altitude around 630' which was pretty good for a rocket of this size. I could have went with a single 24mm

mount but that would have entailed using composite motors only since the drag is rather large even though the weight is

not that much. I used Estes long motor hooks for motor retention. This requires the use of a spacer in each motor tube

but I was using what parts I had on hand in my spare parts boxes. This also let me off from filing the end of the hook

down in case I wanted to use 24mm RMS casings in the future. The all up weight, ready to fly (less motors) is 10oz.

That just a bit less than the predicted 11oz I found when I modeled it on RockSim.

The day of

first flight was nice but a bit on the windy side. I decided to fly anyway. I loaded and prepped the two motors and

installed the recovery system. The rocket slid easily on the 3/16" rod and I hooked up the igniter clips. The

count proceeded to zero, both motors lit and the rocket leapt of the pad. The boost was straight despite the wind. The

rocket reached apogee and the ejection went off and the recovery system deployed perfectly. The rocket descended slowly

under the 24" ëchute. I had contemplated using a separate ëchute for the capsule but decided that the

weight of it did not warrant that. Plus the tower was made of brass tubing and fairly robust. Recovery was perfect with

no damage. Subsequent flights have been repeat performances. The D12-5 is the perfect motor cluster for this rocket. I

have not tried a composite cluster yet but I am sure (2) E18-7's would give out of sight flights.

The day of

first flight was nice but a bit on the windy side. I decided to fly anyway. I loaded and prepped the two motors and

installed the recovery system. The rocket slid easily on the 3/16" rod and I hooked up the igniter clips. The

count proceeded to zero, both motors lit and the rocket leapt of the pad. The boost was straight despite the wind. The

rocket reached apogee and the ejection went off and the recovery system deployed perfectly. The rocket descended slowly

under the 24" ëchute. I had contemplated using a separate ëchute for the capsule but decided that the

weight of it did not warrant that. Plus the tower was made of brass tubing and fairly robust. Recovery was perfect with

no damage. Subsequent flights have been repeat performances. The D12-5 is the perfect motor cluster for this rocket. I

have not tried a composite cluster yet but I am sure (2) E18-7's would give out of sight flights.

Summary

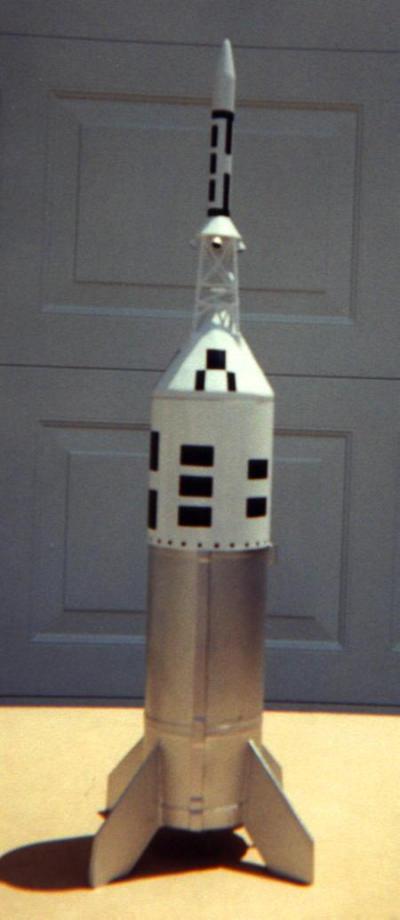

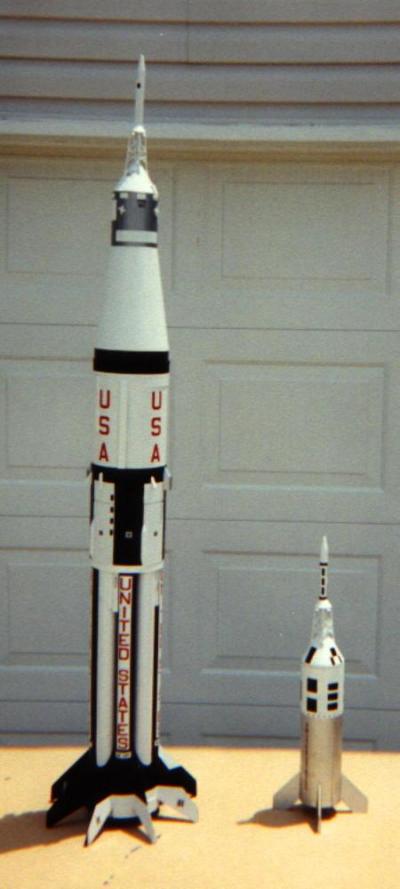

This was a fun rocket to build plus it is a companion to my S1b and in the same scale. It is interesting to put them

side by side for a size comparison. Probably the most time consuming part was building the LES tower. I still feel

soldered brass is the way to go for durability. Other than that there were no difficult or complicated areas to work

on. I received many nice compliments on the LJII since there are not to many around at launches. The flight profile is

perfect too. The D12-5's are the perfect motor choice. This one is definitely a keeper.

Model Stats:

Length: 21.75"

Dia.: 3.1"

Wt.: 10 oz

Motor config.: Dual 24mm cluster

Recovery: 24" rip stop nylon parachute

Sponsored Ads

|

|