Descon 8 Bottle Rocket Original Design / Scratch Built

Scratch - Bottle Rocket {Scratch}

Contributed by Robert Galejs

| Manufacturer: | Scratch |

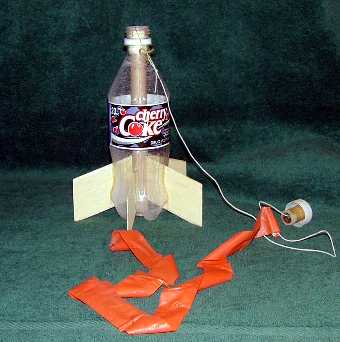

Bottle Rocket

An Easy to Build Fun Flyer

Here's some plans for a very simple model rocket that flies great on C6-3.

Here's some plans for a very simple model rocket that flies great on C6-3.

This bottle rocket weighs 2 oz without the motor so it takes off very quickly, but doesn't fly out of sight due to its 2.6" diameter. It almost doesn't need a recovery device since its so light. The bottle rocket is also quite strong with through-the-wall mounted fins.

VCP calculates the CP to be 3" from rear and the CG is 4" from rear with C6-3 loaded. That's only about 1/3 caliber CP-CG margin but on this short/fat rocket its good enough.

Parts List

Some found parts, some rocket parts. Here's the parts list:

- 20 oz coke bottle

- spent BT-20 estes motor

- 10 " BT-20 tubing

- 1/16" balsa 2" by ~15"

- 1/16" round elastic

- scrap piece of kevlar

- surveyors flagging tape

- small nut and bolt

- masking tape

Construction

Construction

Unscrew cap and use Exacto knife to remove threads from inside of cap, so cap can be put on/removed without turning cap. Drill hole in center of cap to accommodate bolt.

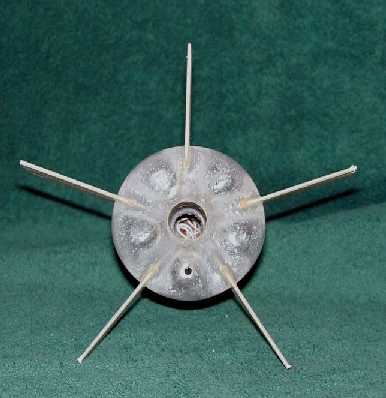

Cut used engine in half. Drill out nozzle so bolt can fit through. Tie a small loop in one end of elastic. Insert bolt through cap, with head on top of cap. Thread spent engine onto bolt, place loop over end of bolt, add nut and tighten.

Cut out circular hole in bottom of bottle for BT-20 to fit. I used an Exacto knife and broke a blade or two, so take your time, the plastic is fairly thick here. There is a small molded circle on the bottom of the bottle that can guide you to ensure your hole is centered. Slowly enlarge it until the BT-20 fits without deforming.

Seal both sides of the balsa with Elmer's fill and finish and sand smooth. I beveled the leading and training edges, but that is not critical. Cut 5 fins at the angle shown in the pictures so that they are 2 3/4" wide root edge to outside edge.

Cut the 5 2" fin slots in the bottle along the grooves in the bottom of the bottle. I used a power miter saw and just eyeballed the length of the cut. If the fin slots are too short, they are easy to elongate with an Exacto.

Insert the BT-20 into the top of the bottle so that it just sticks out of the hole you cut in the bottom. Mark the top of the tube where it sticks out of the top.

Remove the BT-20 and cut along this mark. Wrap masking tape around the top of the BT-20 until it fits snugly in the top of the bottle. Before you install the BT-20, cut off a 1/4" section of the half of the engine casing you didn't install in the cap. Glue this into the end of the BT-20 opposite the tape using another spent engine as a depth gauge. Insert the depth gauge until you have about 1/4" protruding and then immediately remove it, so it doesn't get glued in. Insert the BT-20 into the top and through the bottom hole. Press into place until the top of the BT-20 is just below the lip of the bottle.

Test fit the fins and adjust the fin slot length as necessary. I used double glue joints in gluing the fin onto the BT-20 with yellow wood glue. When the glue has dried, add fillets along the fin/bottle joint. I used thick CA which ended up clouding the inside of the bottle somewhat as the fumes reacted with some residual moisture. Maybe plastic model cement would be neater...

Test fit the fins and adjust the fin slot length as necessary. I used double glue joints in gluing the fin onto the BT-20 with yellow wood glue. When the glue has dried, add fillets along the fin/bottle joint. I used thick CA which ended up clouding the inside of the bottle somewhat as the fumes reacted with some residual moisture. Maybe plastic model cement would be neater...

Tie a loop in one end of the kevlar and thread the other end through a long curved sewing needle. stick the sewing needle into the top of the bottle and through the BT-20 far enough down to not interfere with the "nose cone" and continue all the way through the plastic bottle. pull the kevlar through, leaving the loop sticking out of the top. Tie a big knot in the end of the kevlar that pierced the bottle, pull it tight against the side of the bottle and CA it into place. Tie the loose end of the elastic onto the kevlar loop and attach a piece of surveyor's flagging tape onto the elastic as a streamer. No need to worry about zippering since the kevlar presses against the edge of the bottle.

For the launch lug, just drill a small hole into one of the bumps on the bottom of the bottle big enough for your launch rod to fit. Insert the rod and mark where on the upper bottle the rod touches it when the rod is parallel with the BT-20. Drill a hole here as well. Test fit your launch rod and enlarge the holes as necessary to let the launch rod slide smoothly.

Friction fit an engine, put in some wadding, roll up the streamer and insert, stuff in the elastic and pop on the nose cone. Put it on the rod and launch.

Enjoy a fun flight on a rocket that violates many of the usual rules of thumb (3.5:1 length to diameter ratio, 1/3 caliber stability margin) but still flies perfectly well.

photo by Bill Spadafora

Flying the Bottle Rocket

I've flown it 3 times on C6-3s and never had a stability problem. This is due, in part to the speed at end of rod, about 52 ft/s w/3 ft rod. See launch picture. Launch clips are caught in mid air, but the rocket is a blur. At these speeds, even in modest winds, the angle of attack is quite small. If you don't like this small of a stability margin, adding a small weight to the nose can bring the CG forward substantially, but it is not necessary.

wRASP calculates the altitude of 200' on a B6-2 and 300 ' on a C6-3. It turns out (by no planning on my part) that 2 oz is just about optimum mass for a rocket of this diameter.

Sponsored Ads

|

|