Modification Big Bad V-2 Daddy Modification

Modification - Big Bad V-2 Daddy

Contributed by Michael Bade

| Manufacturer: | Modification |

| Style: | Scale |

How to Make a V-2 out of an Estes Big Daddy

How to Make a V-2 out of an Estes Big Daddy

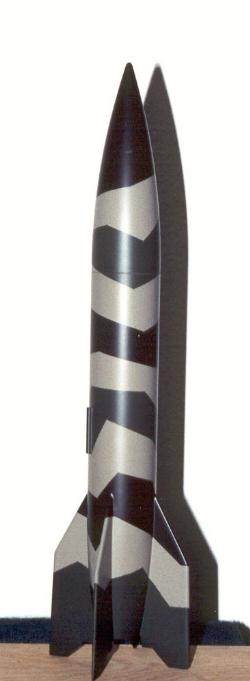

Frustrated with the lack of availability of an affordable V-2 kit, I started thinking of ways to come up with a cheap and easy kit-bash from an existing in production kit that wouldn’t involve a lot of money or time. I also wanted to make a model as big as I could that would still fly on Estes "D" engines, again for cost reasons.

I first considered using a Silver Comet kit as others on the EMRR website have done, but that kit, while still available, is now out of production. Additionally, the result of making a V-2 out of a Silver Comet is essentially a stock Estes V-2 (kit#1904) and I wanted something a little different if possible. I decided to make a V-2 out of an Estes Big Daddy.

|

|

The Big Daddy is a 3" dia. kit that stands 19" tall. I figured that if I got an extra nose cone, cut off the end and stuck it onto the back of the rocket, it would work as a nice tail cone. All I would need to do is slot the cone for the four fins and modify the engine mount. Although I didn’t set out to make a perfect scale model of a V-2, I wanted to come as close as practically possible. I found a set of scale plans for the old Estes Maxi-Brute V-2 on JimZ’s website. (kit# 1267) These plans also included the actual dimensions of the real V-2 rocket. Since the body tube diameter is fixed at 3", I divided the actual V-2 Diameter of 65" by 3 and came up with a factor of 21.67:1. Dividing the length by that factor, I came up with 25.5". In order to get a template for the fin shape, I took the plans I got from JimZ and blew them up on a copier until the body tube diameter was 3". I then traced the fin shape from the photocopy. I added a fin tab on the root edge of the fin that would pass through the side of the tail cone and attach to the engine mount. I also measured the body diameter at the tail from the photocopy and got 1.75". I eye-balled the cone and decided that cutting it about 3.25" from the tip would give me a 1.75" diameter. This makes the exposed part of the tail cone 5.75" long. Since the nose cone is 9" and the tail is 1.25" off the ground, the body tube would need to be 9.5" I purchased a Big Daddy kit on eBay for $14.95, and started checking hobby shops for an extra nose cone. Apparently, that particular nose cone isn’t available by itself. I called Estes intending to purchase the nose cone. They ended up mailing me two nose cones free of charge. (What a great company!) I also bought a sheet of 3/16x4x36 balsa ($2.99) and three 18" BT-50's for ($5.99). I wanted a longer engine mount to go through the length of the tail cone and into the body. The mount that comes with the Big Daddy is pretty short. While waiting for the Big Daddy to arrive, I cut out the fins, leaving the tang on the root edge extra long, and sanded them to the proper shape. When the Big Daddy arrived in the mail I was disappointed to see the four huge slots in the body tube for the Big Daddy’s fins. I have already built a Big Daddy but had forgotten about those slots. I went ahead and started working on the tail cone anyway. I first marked the lines I wanted to cut for the fins to go through the tail cone. I used the mold marks on the cone as guides for two of the fins and measured halfway between for the other two. Suddenly, the slots in the body tube weren’t as bad as I originally thought. I used them to help line up the lines on the tail cone. In order to keep the construction simple, I cut 1/8" slots in the cone and then shaved the edges with a sharp exacto knife while sighting along them to the four slots in the body tube. I widened them until I had a nice friction fit when inserting the fins. I made the slots about 3.25" long, leaving about 1.25" of tail cone in front and back to give it strength. I cut the slots before cutting off either end of the cone so the ends would add strength to the structure as I worked with it. After the slots were done I cut 3.25" off the tip of the cone and then cut off the back of the cone leaving about 0.5" to glue inside the body tube. The tube supplied with the Big Daddy is 10" long. Since the body tube is slotted and I was more interested in ease of construction than to build a model perfectly to scale, I decided not to cut the body tube back to 9.5". I epoxied a strip of 1/16 balsa about 3/8" wide behind each of the fin slots. Then I cut a thin strip of balsa and epoxied that inside each slot. After the epoxy cured I sanded the balsa flush with the body tube. I then applied a coat of CA to give the balsa some strength. I finished filling the gaps with Bondo Spot Putty. Thinking I wanted to do a really good job filleting between the fins and the engine mount I decided to glue the engine mount and fins into the tail cone before I glued on the body tube. I cut a BT-50 to 11" long and attached the engine mount hardware. Then I glued one of the centering rings into the body tube, just in front of the balsa I had used to cover the fin holes. The other centering ring I cut down and glued it inside the tail cone about 3/8" in from the bottom. After it cured I glued the engine mount into the tail cone centering ring and friction fit the body tube onto the other end of the engine mount to keep it centered. After that cured, I took the body tube back off and trimmed the fin tangs and glued them to the engine mount. When I had finished gluing and filleting the fins, I glued on the body tube. Then I put a bead of epoxy around the engine mount at the front centering ring. Having done it this way, I wouldn’t recommend putting the fins on before the body tube. After fitting the fins, I had moved the engine mount off center slightly and when I put the body tube back on, there was a gap between the body tube and the tail cone of about 1/32 of an inch on one side. It's no big deal, the rocket is still straight, but it is another gap to fill and I don't think I gained much fin strength over just sticking them in from outside the body tube. All other construction details pretty much mirror what is in the Big Daddy’s directions. I finished it using a camouflage color scheme. Including paint and glue, I have less than $40.00 invested in this rocket, and that’s about what the out of production kits cost, just for the kit. I have another Big Daddy kit that I am also going to make into a V-2, only I’m going to use a 29mm engine mount and Basswood fins, so I can try flying it on larger engines. If anyone has any better ideas on how to fill those pesky slots in the body tube, please let me know. |

UPDATE 02/02:

UPDATE 02/02:

I have flown this rocket seven times since I submitted this article. I am very pleased with its performance. I first launched it with an Estes D12-3. It had a slow and realistic lift-off and probably went about 400 ft. up. Fortunately there wasn't that much wind that day and the flight was relatively straight. I then used a new Estes E9-6. This was also a slow and graceful lift-off and flight. There was some windcocking evident, even in a light breeze though. I then launched it with an Aerotech E30-7T, and this rocket is the perfect match for that engine. It snaps off the launch pad and goes straight up, even in breezy weather. I've flown it on the E30 three times and each time the ejection went right at apogee. It really gets up there on that engine! I few it with an E9 again later (pictured here), only this time in wind. The low thrust of that motor caused massive windcocking. As the time delay started, the rocket was already traveling perpendicular to the ground. For the next six seconds, it arced over and started accelerating downwards. The ejection charge went off about 100 ft off the ground and the chute immediately stripped. I thought for sure that I was going to find rocket parts when I went looking, but due to a well placed yucca plant, I recovered a scratched, but otherwise undamaged airframe!

I would like to thank the members of "CRASH" (NAR #482) for encouraging me to launch at their bi-monthly launches, and also for all the great positive feedback.

#Related Reviews

- Modification Bad Dad By Larry Brand

Brief: I modified the Big Daddy kit to replace the stock nose cone with a fixed nose cone made from a PET soft drink bottle; parachute deployment is from an open "mortar" mounted on the bottle opening. Rationale? I swiped the nose cone from a family member's Big Daddy kit to use in a building ...

- Modification Big Daddy (29mm) By Stephen Morrow

Brief: Modified Estes Big Daddy to fly on 29mm motors. Modifications: I started this project with a regular Estes Big Daddy. When I bought the kit I knew I wanted to mod it to a 29mm so I bought a motor tube and cut it to a length that would allow it to come up and touch the base of the nose ...

- Modification Big Daddy (29mm) By Sascha Grant

I've always liked the Estes Big Daddy, but even flying on an E just wasn't good enough. So I went about building this to fly on a H - the H128 specifically. Components Out of the box, the kit includes: Nose Cone Centering Rings Pre-Slotted Body Tube Motor Mount ...

- Modification Big Daddy (3) By Mike Goss

A modification to the Estes Big Daddy to use much less wadding. Modifications: The Estes Big Daddy is a short, fat rocket. With this being the case, there is a large volume in the interior of the rocket that needs to be filled with wadding to protect the parachute. I am always looking for ...

- Modification Big Dipper Daddy By Dick Stafford

I bought this Big Daddy (on sale, of course) as a test-bed for a Micro-Hybrid motor. This required an extension of the motor mount, and the capability to house electronics in the nose cone. Before flying it on a Micro-Hybrid, I'll probably try it on a conventional motor with motor ejection (1st ...

- Modification Big Wild Daddy By Tony Turley

The Estes Big Daddy first caught my eye hanging on the rack at WV Hobbies in the fall of 1998. It looked to me to be a good candidate for conversion to 29mm power, so I put it on my Christmas list. My request was granted, and away I went. My first decision was to evaluate the kit parts to see ...

- Modification Dig Baddy By Yitah Wu

What is it about the Fat Boy, Onyx, Minie Magg, etc, that makes grown men's knees weak? I don't know, but the Big Daddy has it - and lots of it. I swung by Commonwealth Displays a couple of times, but they were out of the kit. The second time I was beat out by a telephone order by an hour or ...

- Modification The 'Big Daddy' Educator By Joy Sills

The Educator is a modified Big Daddy. The modifications include adding a 12" payload section and using basswood for fins and centering rings. Modifications: The first modifications were adding basswood fins and centering rings. The second modification was adding a payload section. This was ...

- Scratch 3D Mega Daddy (3D MD) By Steve Lindeman

I was playing around with my Estes 'Big Daddy' one day when I discovered that its NC would fit the tube that my Aerotech Initiator came packed in. The decision was then made to acquire another Big Daddy and build the 3D Mega Daddy (3D MD). Components Only 3 components ...

Related Products

Sponsored Ads

|

|