| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar |

| Published: | 2015-02-01 |

| Diameter: | 1.65 inches |

| Length: | 45.75 inches |

| Manufacturer: | Giant Leap Rocketry  |

| Style: | Sport |

Brief

Brief

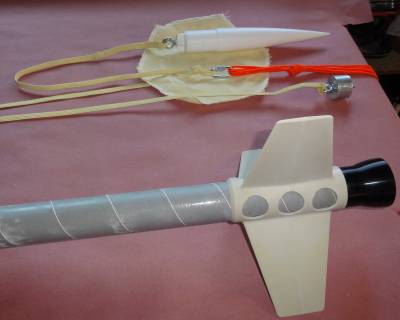

The Giant Leap Rocketry T-Bolt is a member of their "Almost Ready To Fly" rocket kits. It is a single deployment, 38mm minimum diameter rocket kit that comes with all of the necessary parts. The only option at ordering is a 38-to-29mm adapter for 29mm motors.

Components

The kit contains:

- 36" long 38mm "Magna-frame" tubing

- 38mm 5-to-1 Pinnacle nosecone

- 38mm Slimline Bell Retainer (threaded with ring and tool)

- 38mm High-Performance Acme Fin Canister

- 12' Kevlar shock cord w/pre-sewn loops

- Kevlar chute protector

- 36" Rip stop chute

- Aluminum conformal rail guides with spacers (due to bell retainer)

- Hardpoint Anchor to secure the shock cord to airframe (includes eye bolt hardware)

- Threaded Quick-link

- Eye bolt for nosecone shock cord attach

- Vinyl Decal

- Step-by-step instructions (5 sheets)

- Wood stick for application of epoxy for super mount

Construction

When Giant Leap says "Almost Ready To Fly" they mean it. If anything this rocket may be a bit too easy to assemble, but as a quick entry to HPR this does the job. The actual time spent working on the kit was very short, most of the construction time was waiting for epoxy or paint to dry.

The instructions are clear, including cautions around the tricky parts and advising what types of epoxy to use for the different parts. There was one part of the instructions (for a T-Bolt ordered mid-2013 and another mid-2014) that were a bit out of date, they replaced the old shock cord mount (what they seemed to call a "super mount" which was a coupler tube with pre-cut all-thread inserted) with a cylindrical metal piece with a hole through the center for an eye bolt and nut (what they call the "Hardpoint Anchor", sold separately on their site). So the instructions include applying epoxy to the all-thread so it doesn't cut the shock cord, but that's not a problem with the eye bolt. It left me a bit confused since I wasn't familiar with the term all-thread so I was looking for something I didn't have in my kit. But installing the Hardpoint into the rocket is basically the same, and attaching the shock cord to the eye bolt is easier than reaching in to access the buried all-thread I'd imagine. The shock cord included loops at both ends that looked very solid. The kit instructions for attaching at the super mount end was obviously wrong, but the instructions for the eye hook end could easily apply to both ends. The instructions suggest tying the cord to the eye bolt and using a dap of epoxy, I fed the loop ends through the eye hooks and then fed the entire shock cord through the loop and didn't bother with any glue.

To assemble you basically glue on the retainer and fin can (JB Weld and 30 min epoxy recommended, respectively), attach the shock cord to the Hardpoint and epoxy it in (they recommend 30 min epoxy, I used JB Weld here also, and they provide a "glue stick" to reach inside the tube to apply the epoxy), slide on the chute protector and attach the other eye bolt for the nosecone attachment. All 3 GLR kits I've tried now (2 T-Bolts and 1 Firestorm 54) didn't have the hole in the nosecone properly sized for the eye bolt provided, so I've needed to re-drill the hole to make it a bit bigger (but not too big to keep a good bite on the plastic). Easy to do obviously, but a drill and drill bit aren't in their list of required parts. Tie a loop in the shock cord and attach to the parachute with the provided Quick-link. Epoxy on the rail guides with their spacers (two sets of epoxying, JB Weld again), drill the vent holes and it's ready to go.

It doesn't get any easier than the single-piece fin canister, of course without gaining any skills about attaching fins to a rocket. As a minimum diameter rocket it does add to the rocket's outer diameter at the bottom, surely adding a bit of extra drag, and it's a pretty solid chunk of plastic so it's reasonably heavy. In this kit GLR drills some large holes on the tube portion to reduce the weight, making what they call the "High-Performance" Fin Can. But the single-piece fin can avoids having to worry about alignment, fillets, etc. Perfect for someone just getting started.

Finishing

The "Magna-frame" tube is a spiral tube, "interlaced with layers of gray vulcanized fiber and phenolic" per their website. It's apparently sealed from moisture inside & out, I thankfully haven't had any wet landings yet on my GLR Magna-frame rockets to test that claim. It does result in the spiral going around the body tube, which one likely wants to try to fill in. I used one generous application of DAP Drydex to fill the gaps and sanding to smooth the whole surface, it felt smooth to the touch but the spiral was still faintly visible after painting (either this was a poor choice of filler or perhaps needed another coat or more sanding or something). The instructions don't mention filling the grooves until after all assembly, I did this first thing before any gluing since I thought it would have been hard to work around the various things that get glued on the outside.

Sanding and painting was as one would expect, with a few sentences of suggestions in the instructions. After initial sanding I used a Rustoleum gray paint+primer, followed by more sanding and a Rustoleum blue for the entire rocket. The spacers for the rail guides feel a bit hack-ish (they're just pieces of a larger diameter coupler I believe, so the inside curve matches the outer curve of the tube), but I think necessary due to the extra diameter of the bell-shaped retainer to get the extra rail clearance. It's too bad there isn't just a taller version of the aluminum rail guides to get the extra clearance. It leaves a few more 'warts' on the rocket and is obviously more to paint and epoxy (I decided to paint the tube and the spacers first, then sand them down and apply the epoxy to avoid having to mask-off the aluminum bits). I've also found the local launch groups (AeroPac, TCC, LUNAR) aren't that thrilled about the aluminum guides, they'd prefer plastic rail buttons, less chance of binding and damaging the rail. But it's a minimum diameter rocket, so it seems like it would have to be something that purely glues to the outside, not bolting through to the inside where it could interfere with the motor or parachute. AeroPac suggested applying some silicon lubricant before launching, so I bought some and have sprayed the guides before each launch since. The guides do have a groove down the middle that can help with alignment (to run a string or yardstick through between the two guides), so it's possible to attach them very straight I believe and reduce the risk of binding.

I did not use the provided decal. It looks fine but I just didn't feel like using it. The bell-shaped retainer looks cool, though being the opposite of a boat-tail I suspect has the opposite effect on aerodynamics as well.

So I would rate the construction and finishing at least a 4. I can't quite call it a 5 due to the slightly outdated instructions, fairly deep grooves in the tube to be filled, and the spacers on the rail guides. But these are pretty minor things given the simplicity and completeness of the design. If there was a 4.5 option I'd pick that.

Flight

The first flight was beautiful, I got my L1 certification on my very first HPR flight using this kit, and my dad built the same kit a year later and got his L1 his first flight. I used an AeroTech H148R (RMS-38/240), he used an I140W (DMS-38). Unfortunately my second flight was a failure, I moved up to an I280DM and it was a beautiful ascent, but the chute never deployed (I believe because I followed the motor's recommendation of only using 1/2 of the provided black powder for 2.6" or smaller diameter rockets). I had used the full amount when I built the H148R (missing the same recommendation in its instructions, and the L3 who oversaw my building of the motor did not made any comment there), and my dad used the full amount on both of his (DMS) flights without any trouble. Given how durable the Magna-frame tube seems I suspect you can go a bit higher on the BP without risking any damage to the rocket.

Since my second flight was a ballistic landing and the rocket was destroyed. The fin can broke a fin and shifted forwards on the body tube, and a large section of the body tube unraveled. So nowhere near durable enough to survive a several thousand foot drop onto the Black Rock Desert playa, but I suspect very few things would be. Nothing to blame the rocket for, other than perhaps the tightness of the recovery system fit in the 38mm tube.

As a single deploy rocket there is no space provided for an avionics bay. I cut an opening in the nosecone shoulder to allow me to insert a StratoLogger SL100 and 9V battery into the nosecone, basically just taping the two together and padding it (and hopefully protecting it from any ejection gasses) with some fiberglass insulation. The shoulder is fairly long so there's still plenty of length for a snug fit. Unfortunately I didn't get any data from either of my two flights, the first time the 9V battery came unplugged as I didn't think to tape the clip lead on, the second time the altimeter was destroyed with the rocket, I was unable to extract any data from the SPI flash.

Recovery

After doing initial RockSim calculations on the rocket, some L3 friends thought the descent rate was too slow with the provided 36" chute and recommended a smaller one. They liked the 30" numbers better, so I replaced the chute. Even with the somewhat smaller chute it is a tight fit getting it rolled-up and then wrapped in the kevlar protector to fit in the 38mm tube. I applied baby powder to help it slide in (and hopefully out).

So my personal recommendation is for a 30" chute, and don't skimp on the black powder! Baby powder seems like a good idea also.

Summary

I think this is an excellent starter rocket and introduction to HPR. Assembly is easy and it flies great. The included parts all seem to be very high-quality, such as the use of a kevlar shock cord over elastic or nylon and the Hardpoint Anchor for the shock cord attachment. It's a very nice pretty light-weight minimum diameter rocket, it wants to go fast and high. As a single deploy rocket you will probably want to stick with smaller motors for a shorter recovery.

Even though my original rocket was destroyed, I'm considering purchasing another one to use as a night launch rocket, as an easy / durable kit. I would definitely recommend the kit to others.

|

|

Flights

Sponsored Ads

|

|