| Manufacturer: | Modification |

Brief:

Brief:

This is a Quasar Patriot kit with 38mm motor mount instead of 3 x 24mm, through the wall Microlite fins instead of surface mount balsa, lightweight tape-together clamshell electronics bay for dual deployment recovery, shortened nose cone shoulder, and deleted large metal eye bolt for weight savings. Positive motor retention added.

Modifications:

The Quasar Patriot kit, motor, and most of the modification materials were purchased at Apogee and were delivered quickly and without any damage.

This build is all about simplicity and weight savings. The object was to reduce weight by eliminating as much epoxy, steel, brass, and over-engineering as possible. A secondary goal was to design an electronics bay that is less imposing and has simple engine backup for a dual deployment newcomer.

The 3 x 24mm motor cluster was the first thing to go, replaced by a LOC motor tube and foamboard centering rings. The foamboard is extremely light and is perfect for centering rings because there's hardly any thrust against them once the fins are glued in. The Microlite is lighter weight than plywood but is stronger than basswood (although a little more springy), so it was used for the through-the-wall fins. The tabs butt against the centering rings fore and aft, so carpenter's glue is plenty strong for fin can assembly and saves weight over epoxy. At the rear of the rocket, the centering ring was sealed with white glue and allowed to dry, T-nuts were placed for positive motor retention, then the back 1/8 inch was filled with epoxy, which results in a beautiful, flat, finished look and adds rigidity and strength to the motor mount/fin can assembly.

The Quasar Patriot kit has a high power body tube and 1/4 inch launch lug so those were not changed. All but one inch of the thick plastic nose cone was cut off to save weight. A hole was drilled in the shoulder, Kevlar shock cord installed, and the nose cone was glued in using a small amount of epoxy. Thus, the nose cone shoulder becomes the shock cord mount for the main parachute.

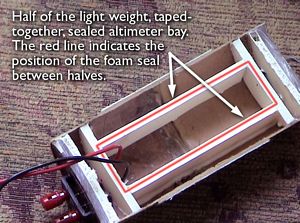

The section with the black and white decal toward the top of the rocket became the e-bay. It is a natural size for available altimeters. Foamboard bulkheads were installed in each end of the e-bay as well as steel picture wire and lying-around speaker wire connectors. The picture hanging wire is forever strong and is lighter than the U-bolts typically installed on e-bays. The bulkheads were sealed with white glue and allowed to dry. Holes were drilled around the lip of the couplers and then taped and poured with epoxy (this provides a positive "key" instead of relying just on the adhesive properties of the epoxy). The e-bay was then cut in half using a razor saw. To isolate the altimeter from ejection gases, an inner chamber was built from foamboard. It is sealed around the joints with fillets of white glue. A foam seal goes on the rectangular surface which fits together and seals air-tight. An air escape hole was drilled into this chamber for the altimeter. When the two halves of the clamshell are brought together, the chamber seals and the halves are taped together around the shoulders on both ends of the electronics bay so there are no tape joints on the outside of the rocket.

The section with the black and white decal toward the top of the rocket became the e-bay. It is a natural size for available altimeters. Foamboard bulkheads were installed in each end of the e-bay as well as steel picture wire and lying-around speaker wire connectors. The picture hanging wire is forever strong and is lighter than the U-bolts typically installed on e-bays. The bulkheads were sealed with white glue and allowed to dry. Holes were drilled around the lip of the couplers and then taped and poured with epoxy (this provides a positive "key" instead of relying just on the adhesive properties of the epoxy). The e-bay was then cut in half using a razor saw. To isolate the altimeter from ejection gases, an inner chamber was built from foamboard. It is sealed around the joints with fillets of white glue. A foam seal goes on the rectangular surface which fits together and seals air-tight. An air escape hole was drilled into this chamber for the altimeter. When the two halves of the clamshell are brought together, the chamber seals and the halves are taped together around the shoulders on both ends of the electronics bay so there are no tape joints on the outside of the rocket.

Construction:

12 inch LOC motor tube, foamboard centering rings, 2 T-nuts, foamboard bulkheads for e-bay, foamboard inner sealed altimeter chamber, foam seal, 2 additional BT-80 tube couplers, 1/8 inch Microlite for the fins, steel picture wire for e-bay shock cord anchors, speaker connectors for ejection charge hookup, Kevlar for shock cord, and Nomex chute and streamer protectors.

The Quasar Patriot begs for more power. The modified motor mount/fin can is lightweight and plenty strong for high power. The foamboard inner electronics chamber is not a quick build, but it is simple, strong, and lightweight. A pull-pin switch was added to activate the electronics on the pad.

Finishing:

The model was finished with three coats of high-build automotive primer, sanded in between coats, then top-coated with glossy automotive paint. The provided Quasar decals are stick-on, are high quality, and easy to work with.

Flight and Recovery:

First flight was with a G76-10G Mojave Green reload. Performance was excellent and appeared to be much higher than the 2400ft predicted in RockSim. Motor ejection is used as backup. With the Nomex protectors, the ten foot Mylar streamer, and the 24 inch parachute are a quick pack. With two screws retaining the motor, it is also quick and simple to install. The model flies straight and is quick off the pad.

The 20 feet of braided Kevlar shock cord worked fine. On the first flight, the altimeter hole was occluded by some foam rubber and the altimeter was not activated. Recovery velocity was too fast on the streamer, but there was no damage of any kind, which proves the concept of using the foamboard and Microlite for weight savings.

Summary:

PROs: The Quasar Patriot comes with a body tube and nose cone that are much juicier than just a 3 x 24mm kit. Their Bio Hazard II is the same deal. The decals on these kits really set them apart and they're a very inexpensive way for a person to start into dual deploy without the expense of a typical L2 cert sized rocket. If a flight problem occurs, the cost of repair is lower and the materials give added protection to the altimeter compared to a rigidly mounted plywood and metal sled. The learning curve is not as steep with these materials either.

CONs: The foamboard inner chamber takes a little patience but probably less than building a sled.

With the materials described here, the final dual-deploy launch weight (including altimeter and 9 volt battery) is only 699 grams. The regular low-power version, built as it's packaged, weighs 419 grams and can be flown to 300 feet on 3 C11s.

Related Products

|

|

Flights

Sponsored Ads

|

|