Scratch Mini V2 Original Design / Scratch Built

Scratch - Mini V2 {Scratch}

Contributed by Dick Stafford

| Manufacturer: | Scratch |

Brief:

My Mini-V2 is a semi-scale model based on BT-50 tubing. I was motivated to

build this V2 after seeing plans for a BT-20 version that appeared in the

January 1989 issue of American Spacemodeling. The Mini-V2 is a simple model and

was constructed using "scrap" materials laying around from other

projects.

Construction:

Materials used:

- Two PNC-50 nose cones (2.75" long), one is used for the tail cone

- BT-50 (4")

- BT-5 (~2 ¼")

- Used engine casings for centering ring (24mm, 18mm)

- 1/8" balsa fin stock

- Motor hook for mini motors

- 1/8" wide elastic shock cord

- Plastic streamer

- Launch lug

- Clay for nose weight

Construction of most of the rocket is pretty basic, and needs no

elaboration. I used yellow glue for the paper-paper joints and epoxy for the

paper-plastic joints.

Construction of most of the rocket is pretty basic, and needs no

elaboration. I used yellow glue for the paper-paper joints and epoxy for the

paper-plastic joints.

Tail cone assembly: Insert the tip of one cone into the BT-5 tubing and mark. Cut the end of the cone off (~1 3/16") so that the BT-5 tube will just fit. Also, cut off the end of the nose cone immediately before the shock cord attachment. Using ½" sections of the 24mm and 18mm casings, make a ring to center the BT-5 in the nose cone shoulder. This requires some peeling and, of course, other materials can be used. Install the engine clip so that the engine extends about 3/8" from the motor tube. Make a 3/8" long x 1/8" wide notch in the end of the boat-tail to accommodate the engine hook. Test fit the engine mount and make sure the engine hook works when installed in the tail cone (engine tube flush with the end of the tail cone). Glue it all together.

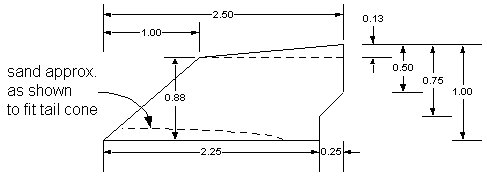

Fins: Make a template using the attached diagram. Note that I was not careful with these dimensions and they can probably be improved by referencing Pete Always's book or other on-line resources. Most any scrap balsa can be used, but I used 1/8". Make sure the grain is parallel to the leading edge, etc. Holding sandpaper on the boat tail, sand the root of each fin so it conforms to its curve. Glue the fins on such that they overlap the BT by ¼".

Nose weight: Add clay to the nose so that the CG without an engine is 3 7/8" from the tip of the nose cone.

Flight:

This model has "flown" 4 times on A10-3 engines. On the first try,

the nozzle blew through. The Mini-V2 attained an altitude of about 10 feet and

ejected on the ground. The second try was picture perfect. A ¾" x

3" plastic streamer brought it down safely about 50 feet from the pad.

This is a good model for small fields. On the third try, the 1/4" lug

bound on the 3/16" launch rod and the V2 stuck there. Suggestion: use a

lug for a standard rod. The fourth and final flight (to date) was also

successful.

Summary:

PROs: 1) Easy to build, 2) Looks nice, 3) Gets positive comments from other

fliers. CON: 1) Not 100% scale.

Sponsored Ads

|

|