| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstar_borderstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Apogee Components  |

Brief:

A basic Rota-roc style helicopter (fixed blade), this is a reliable design and

definite crowd pleaser. There's just something cool about a true helicopter

recovery rocket.

Construction:

The kit arrived within 3 days of placing my order online and all components

were complete and good quality. Parts list includes:

- BT-5 body tube

- 10.5mm motor tube and centering rings (optional/see notes)

- Balsa nose cone

- Balsa fins (3)

- Balsa blades (3)

- Copter hardware (hinges, thread, wire, rubber bands)

Apogee's instructions are very well written, featuring good illustrations, and make this a manageable build even if it's your first helicopter. This was my second Heli-roc kit. My first is a favorite flyer with about 15 flights and still going strong. This one was built for the 2005 EMRR challenge. I wanted to try to improve on its performance a bit and include a few tips along the way.

Construction starts

out with prepping the fins. One of the key decisions you'll make on this is

whether or not to paint the rocket. Typically, "performance" rockets

do not get painted, but need some treatment of the unfinished balsa to avoid

warping. For my first one, I painted the blades yellow and the body green (sort

of like a flying dandelion). The added weight definitely hurt altitude

performance. For this build, I treated the fins with a very thin clear dope

after sanding in a simple airfoil.

Construction starts

out with prepping the fins. One of the key decisions you'll make on this is

whether or not to paint the rocket. Typically, "performance" rockets

do not get painted, but need some treatment of the unfinished balsa to avoid

warping. For my first one, I painted the blades yellow and the body green (sort

of like a flying dandelion). The added weight definitely hurt altitude

performance. For this build, I treated the fins with a very thin clear dope

after sanding in a simple airfoil.

Next up is marking

the tube. This is a bit more complicated than drawing 3 fin lines, so pay

careful attention the instructions. This uses a burn string method to deploy

the blades, which means vents are needed for the gases. Placement of the vents

needs to go above the blades and oriented in a way to avoid the rubber bands.

The template included in the instructions helps make sure everything is lined

up just right.

Next up is marking

the tube. This is a bit more complicated than drawing 3 fin lines, so pay

careful attention the instructions. This uses a burn string method to deploy

the blades, which means vents are needed for the gases. Placement of the vents

needs to go above the blades and oriented in a way to avoid the rubber bands.

The template included in the instructions helps make sure everything is lined

up just right.

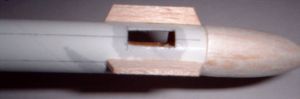

After marking the tube and cutting out the vents, you bond the nose cone to the end of the tube. My nose cone shoulder was a bit too long, partially blocking the vents. This was easily corrected with a utility knife. If you want to get more than a dozen flights, you'll want to coat the base of the nose cone with a thin layer of epoxy before bonding it.

The kit comes with an optional 13/10.5mm motor adaptor. Since 10.5mm motors are no longer available (or certified), I skipped this. This kit has obviously been around for a while and the adaptor is of no use today.

Fin attachment is standard, although I used CA to speed things up a bit. Very thin and light fillets are in order here, as they get covered by the blades in flight and are of no aerodynamic benefit.

The instructions call out a split launch lug approach (one low/one high). I chose to avoid the lugs entirely and use the corner formed where blades join as the launch guide. This helps reduce the drag slightly on what is a fairly high drag design.

The blade construction and mounting are by far the most challenging aspect of this kit but the instructions walk you through it fairly well. For starters, helicopter blades do not get the symmetrical airfoil found on most rocket fins. They are only airfoiled on the top surface. Also (and this is not noted in the instructions), you only need to airfoil about 2/3 to 3/4 of the length of the blade, working from the outer tip inward.

After airfoiling, I decided to apply Japanese tissue for strength and color, which adds only a very slight amount of weight. To apply the tissue, brush on a solution of 50/50 Elmer's white glue and water, press and stretch the tissue, and rub out any wrinkles with your finger. After the glue has dried, trim away excess with a knife blade. I finish it off with a light wipe with rubbing alcohol to shrink the tissue.

Mounting the blades

is where I benefited most from the "do over" experience between kit

#1 and kit #2. The hinges are nylon and bonding nylon to a paper tube requires

a good CA (I used the Zap green bottle stuff). Getting even a tiny amount of CA

in the hinge will ruin everything but going too skimpy on the CA will result in

a poor bond and you might lose a blade as a result. I folded my blades over and

dipped the hinged edge in Vaseline, making sure the hinge joint was well

coated. This keeps the CA out and was very effective. With the greased hinge

joint in place, I then CA'd the hinge to the blade using an alignment template,

then tacked the other end of the hinge to the body tube. The alignment is

critical because you need a roughly 8 degree angle on the deployed blade for

maximum lift. The tack to the body tube is supposed to be light--it just holds

the blades in place. Once the blades are in place, you wrap a line of Kevlar®

around them and coat the Kevlar®

with thin CA to permanently bond them.

Mounting the blades

is where I benefited most from the "do over" experience between kit

#1 and kit #2. The hinges are nylon and bonding nylon to a paper tube requires

a good CA (I used the Zap green bottle stuff). Getting even a tiny amount of CA

in the hinge will ruin everything but going too skimpy on the CA will result in

a poor bond and you might lose a blade as a result. I folded my blades over and

dipped the hinged edge in Vaseline, making sure the hinge joint was well

coated. This keeps the CA out and was very effective. With the greased hinge

joint in place, I then CA'd the hinge to the blade using an alignment template,

then tacked the other end of the hinge to the body tube. The alignment is

critical because you need a roughly 8 degree angle on the deployed blade for

maximum lift. The tack to the body tube is supposed to be light--it just holds

the blades in place. Once the blades are in place, you wrap a line of Kevlar®

around them and coat the Kevlar®

with thin CA to permanently bond them.

Construction wraps up with the deployment stuff. On the blade, this is a balsa piece mounted perpendicular to the blade with a tiny J-hook formed from the included music wire. On the other end, there's a J-hook mounted into the nose cone. A rubber band joins the two and snaps the blade up into place when the burn string breaks. I was pleased that this kit comes with extra rubber bands, as these are too tiny to find at the office supply store when you lose or break them. Of course, between building both kits, my son went through braces and I managed to score about 1000 "free" replacement bands (ignoring the obvious dent to the wallet for the braces themselves).

The last aspect of construction is drilling the holes for the burn string. Since snagged burn strings are a common failure in competition, one tip I'll pass along is to put a drop of thin CA on each hole, then use a small file to smooth the edge.

After drilling for the burn string, it's also a good idea to apply a layer of mylar tape to the underside of the blades where the gasses come out opposite the drill holes.

Finishing:

As noted, I went with a tissue finish. While it's possible to paint this, I

tried it on my first kit and was disappointed with the results. The paint is

very difficult to keep out of the hinges, adds weight, and really doesn't add

that much to the appearance. The tissue approach adds color for a lot less

weight.

Construction Rating: 4 out of 5

Flight:

While I've had many successful flights on my first model, this one's first

flight was less than spectacular. I was flying in fairly heavy winds (steady

10-12mph and gusting to 15 mph) and decided to try it on an A10-3. It started

fairly well off the rod, but at about 40 feet tumbled over horizontal then

quickly nosed down and flopped on the ground still under power. The delay

kicked in, popped the ejection charge, and the blades deployed perfectly,

albeit way too late to do any good.

No damage, but I'll definitely wait for lighter winds before flying this again. I'd never flown in more than about 6-8 mph winds previously on these models.

Recovery:

My first model generally has had no troubles save for the occasional sticking

burn string. #2 never had a chance on its first flight. I'll post a tip/update

with feedback on further flights as I'm hopeful the lighter build and improved

construction will pay off in better flight performance.

Flight Rating: 3 out of 5

Summary:

If you're interested in helicopter recovery but not quite comfortable trying

the NAR plan or rota-roc on your own, this kit is a great way to start. It's

based on the rota-roc design, reasonably reliable, and backed up with Apogee's

good instructions, great materials, and excellent customer service.

Overall Rating: 4 out of 5

Other Reviews

- Apogee Components Heli-Roc By Alan Rognlie

( Contributed - by Alan Rognlie) I purchased this kit in the summer of 1997, intending to build it for the C HD (Helicopter Duration) event at MWRC-97. Unfortunately, this model is designed for 10.5mm or 13mm motors, so it wasn't appropriate at the time and I set it aside. We're holding a B HD event at 14AL-98 and Apogee makes 10.5mm B motors, so I decided to put this together to have ...

|

|

Flights

|

|

DBM (February 13, 2006)

|

|

M.G. (January 1, 2001)