Nano Rocketry Interdimensional Transfer Ship

Nano Rocketry Interdimensional Transfer Ship

Contributed by Carl Tulanko

| Construction Rating: | starstarstarstar_borderstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

Brief:

Brief:

Nano Rocketry's Interdimensional Transfer Ship, designated ITS, is one in a series of their "fantasy" models made for the MicroMaxx motors. This is a slick ship, with a really cool and complex fin pattern and, as with all Nano kits, is designed both light and fast.

Construction:

The kit came in a envelope which described the contents and displayed a picture of the final product. This was another kit in a series that my daughter won in a recent EMRR photo contest, so we could not wait to get started building. Thanks go out to Nano Rocketry and Nick of EMRR for providing the prize models.

The envelope contained a 6mm x 6 inch long body tube, an unfinished two-piece wood nosecone, Kevlar thread for shock cord, laser-cut balsa fins, a launch lug and a good set of detailed instructions. I was very impressed with the quality of components, especially the accurately cut fins; some of the larger manufacturers could take lessons from Nano in this department. The only problem noticed was the launch lug. This was the first Nano kit I actually received that had a launch lug included, but it was too small to fit the rod so they lost a point with me in that category. Components: 4 of 5.

Construction begins with the nosecone. The nosecone came in two pieces; one piece is the cone rough shaped and the other is the base that fits inside the body tube. Both were drilled for the Kevlar shock cord and initial fit was pretty close. One thing I do not like to do is use the recommended procedure of using CyA for assembling the nosecone and attaching the Kevlar shock cord. I have had way too many of these Nano kits lose a nosecone, shock cord, or both due to the forceful ejection charge of the MicroMaxx motors.

Construction begins with the nosecone. The nosecone came in two pieces; one piece is the cone rough shaped and the other is the base that fits inside the body tube. Both were drilled for the Kevlar shock cord and initial fit was pretty close. One thing I do not like to do is use the recommended procedure of using CyA for assembling the nosecone and attaching the Kevlar shock cord. I have had way too many of these Nano kits lose a nosecone, shock cord, or both due to the forceful ejection charge of the MicroMaxx motors.

Instead of following their recommendations using CyA, I used 5 minute epoxy. I fitted the base to the nosecone, then filled the nosecone hole with epoxy and inserted a new, longer piece of Kevlar thread. A coat of epoxy was also applied to the bottom of the cone and the base was threaded down the Kevlar and held to the bottom of the nosecone with masking tape until the epoxy set. Note that I did not use the supplied shock cord in the kit, but rather cut a piece of Kevlar thread I had to a length over twice the body tube's length. Once the assembly was glued, I put a drop of epoxy at the bottom of the nosecone base for extra hold and suspended the nosecone using the shock cord to help keep the cord stay straight into the base of the nosecone. This made the nosecone assembly very strong and the cord will not pull out of the nosecone hole, as it has done in previous models.

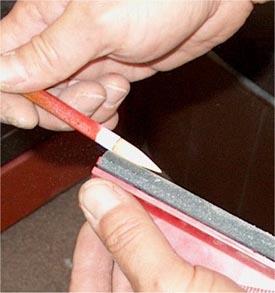

The nose cone was fitted into the end of a fiberglass arrow shaft that was inserted into as drill. This made shaping the nosecone much easier. The drill was turned on and 100 grit sandpaper was used to get the shape I wanted. I smoothed it out with 320 grit, then coated the nosecone with some thin CyA. Once dried, I touched it up with 320 grit sandpaper and it turned the nosecone surface into a near plastic finish.

The nose cone was fitted into the end of a fiberglass arrow shaft that was inserted into as drill. This made shaping the nosecone much easier. The drill was turned on and 100 grit sandpaper was used to get the shape I wanted. I smoothed it out with 320 grit, then coated the nosecone with some thin CyA. Once dried, I touched it up with 320 grit sandpaper and it turned the nosecone surface into a near plastic finish.

Body tube construction was next and the fins were removed from their balsa sheet in preparation for assembly. The template printed in the manual for marking the location on the body tube was not used; instead, I used the "Eye" method for each fin, which worked well. Fins for this model are thicker than the ones supplied in the Nike kit and are of a unique shape. The wood fins are of excellent quality for their size and were laser cut. I set up a work surface by laying out a piece of plastic, then used a ruler as a guide  to make sure the smaller upper fin root was even with the lower fin root edge. Once they were "fit" to each other, I used medium CyA to glue them together. The plastic sheet allows you to glue the fins while they lay on a flat surface. They then easily pop off the plastic once dried; I have used the plastic sheet surface for years in the R/C world when assembling over plans and it works well with rocketry too!

to make sure the smaller upper fin root was even with the lower fin root edge. Once they were "fit" to each other, I used medium CyA to glue them together. The plastic sheet allows you to glue the fins while they lay on a flat surface. They then easily pop off the plastic once dried; I have used the plastic sheet surface for years in the R/C world when assembling over plans and it works well with rocketry too!

Finishing: The model was painted prior to assembling the fins to the body tube. I pushed some "T" pins through the bottom of a cardboard sheet, then pushed each fin's root into one of the pins. This allowed me to easily paint them from all sides. They were primed with Krylon White Primer, then painted using two coats of Testors Red Spray Paint. The body tube was colored using my cheaters method. I cut a piece of Chrome Monokote self-stick

The model was painted prior to assembling the fins to the body tube. I pushed some "T" pins through the bottom of a cardboard sheet, then pushed each fin's root into one of the pins. This allowed me to easily paint them from all sides. They were primed with Krylon White Primer, then painted using two coats of Testors Red Spray Paint. The body tube was colored using my cheaters method. I cut a piece of Chrome Monokote self-stick  Mylar, then laid the tube on the edge and "rolled" the Mylar around it; edges of the body tube were trimmed with a single edged razor. Body tube done!

Mylar, then laid the tube on the edge and "rolled" the Mylar around it; edges of the body tube were trimmed with a single edged razor. Body tube done!

The nose cone was primed with Krylon White Primer, then lightly sanded and painted using Testors Chrome Paint. I then cut away the body tube Monokote in the fin area and used medium CyA to glue them on. A new piece of launch lug from a aileron sleeve was cut, sanded and glued between two fins. Finally, I used a BIG drop of 5 minute epoxy on the knot I tied at the end of the Kevlar shock cord and inserted it inside the top of the body tube about an inch or so. The Epoxy tends to hold the shock cord much better to the inside then CyA and I have been using this method for most of the Nano kits with great success.

Construction Rating: 3 out of 5

Flight: Anyone familiar with the Micro rockets knows there is only one motor available from Quest; the MicroMaxx motors come in packs of six or eight and I really need to invest in Quest stock, as I usually purchase these motors in 100 quantities or larger. To date we have had over 600 launches with MicroMaxx rockets and have long since given up trying to document every flight. The are just plain fun and make great backyard launchers.

Anyone familiar with the Micro rockets knows there is only one motor available from Quest; the MicroMaxx motors come in packs of six or eight and I really need to invest in Quest stock, as I usually purchase these motors in 100 quantities or larger. To date we have had over 600 launches with MicroMaxx rockets and have long since given up trying to document every flight. The are just plain fun and make great backyard launchers.

The motor was fitted into the base of the body tube; placing a piece of masking tape across the top of the motor and overlapping the motor edges gave a nice friction fit. This model, as with all Nano kits uses nosecone separation and freefall for recovery. When hooking up the igniter, you do not use the plug-in socket at the base of the Quest MicroMaxx launch pad. The igniter sits on top of the pad surface and the rocket is placed on the launch rod, then slid down and plugged into the igniter. In order to do this, you need to separate the igniter halves, discard the plastic only half and position the "flat" side so it faces the launch rod.

I was expecting great performance at launch time since I had seen the other Nano rockets smoke off the pad! They perform so much better than the Quest Rockets, since they are 2 to 3 times lighter. This launch was no exception; it shot off the pad and reached a respectable altitude in a hurry. Great launch!

Recovery:

A definite "pop" was heard at apogee, indicating nosecone separation. The model landed safely right next to the pad and we prepped and launched it about 4 more times. I really do like the performance of these models and highly recommend them to anyone wishing to try their hand at micro rocketry. One thing I did make was a motor extraction tool. I cut a piece if 1/8" hardwood dowel to a length of 8", then capped it on one end with a rubber shroud. I now can easily push the motors out the bottom with this tool.

Flight Rating: 5 out of 5

Summary:

The ITS is a really slick looking kit from Nano Rocketry and I highly recommend this kit to everyone. There were a couple problems, such as the wrong launch lug size and shock cord mounting method, but these were easily remedied. These kits are typical of Nano as they are lightweight, very fast and reach some respectable altitudes for their size. It's a real treat to build micro rockets then see them successfully fly and the Interdimensional Transfer Ship is no exception&with this kit you had better get ready for a ride to the stars!

Overall Rating: 4 out of 5

|

|