| Manufacturer: | Scratch |

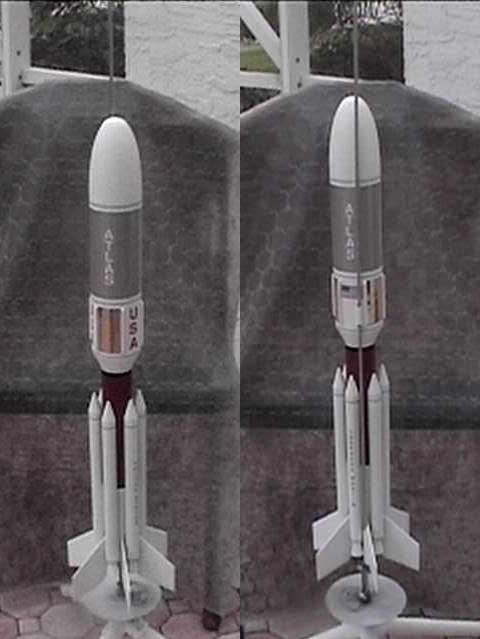

ATLAS

606

by David S. Chen

The Atlas 606 represents Lockheed Martin's next generation heavy lift space vehicle, having a payload volume and lift capacity that matches that of the U.S. Space Shuttle. This model is actually a modified Estes Fat Boy in that it utilizes all components of that kit. The Fat Boy nosecone and body tube are used to make the payload section. The liquid fueled engines are represented by a BT60 tube with transition shrouds constructed by using the VCP shroud template utility. The booster rockets are BT20 tubes capped on both ends by hot gluing plastic nosecones from Fireworks bottle rockets. |

List of Components:

- 1 Estes Fat Boy Nosecone.

- 1 Estes Fat Boy Body Tube.

- 3 Estes Fat Boy fins with through-tube extensions cut off.

- 3 cloned fins from 3/32" balsa of Fat Boy dimensions.

- 6 6" pieces of 3/32" basswood strip.

- 6 2.5" pieces of 3/32" basswood strip.

- 1 14" long piece of BT60 tube (2.5" to be recessed inside the BT80 tube).

- 6 9" long pieces of BT20 tube.

- 6 18mm diameter cardboard circles.

- 1 5" long piece of BT50 tube for use as an Engine Tube (3.5" to be recessed inside the BT60 tube.

- 12 Plastic nosecones from medium sized Fireworks bottle rockets.

- 1 Burger King Straw for use as launch lug material.

- 4' length of .25" elastic cord.

- 1 Estes C engine spacer.

Construction:

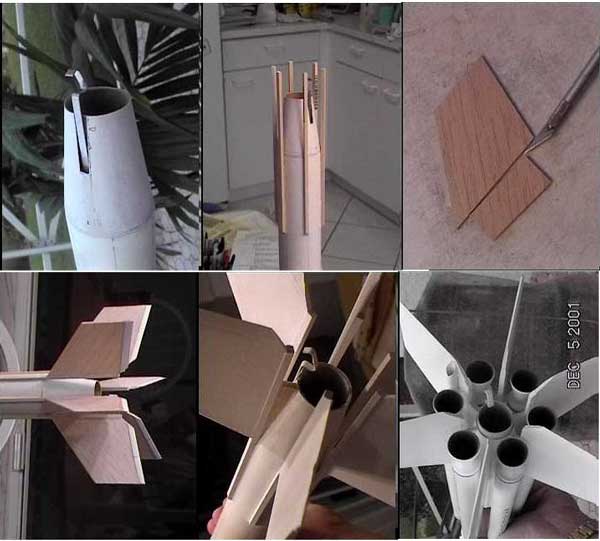

Basically, the centering rings that came with the Fat Boy kit were cut into a pair of BT80-BT60 and BT60-BT50 rings. These were utilized to glue the engine tube into the aft end of the BT60 tube and to glue the BT60 tube into the BT80 tube. Leave 10.5 inches of BT60 tube exposed below the transition under the Payload fairing. An Estes Engine hook was attached to the engine tube using the BT60-BT50 centering rings such that .25" of engine would protrude beyond the end of the engine tube. A 1 inch long BT80-BT60 transition shroud and 1.5 inch long BT60-BT50 transition shroud were glued at the appropriate locations (download free VCP software to generate templates for these shrouds). The 6 shorter length basswood strips were used to cover the fin slots on the BT80 tube and spaced evenly. The 6 longer length basswood strips were glued to the sustainer extending 2.5 inches beyond the front end of aft transition. The Fat Boy fins were trimmed of the through-the-tube sections. The fins were glued to the basswood strips with the leading edge of the root chord even with the front end of the aft transition. Wedges of 3/32" balsa were cut and glued between the strips and transition section. Fins were then sanded to given them a rounded leading edge and tapered trailing edge which was reinforced with paper. Launch lugs were cut from the plastic straw and attached to one fin and in an appropriate spot on the Payload fairing. The booster rockets were constructed from 9 inch long sections of BT20 tubing. Sections of an estes C engine spacer and hot glue were utilized to glue the nosecones on. The bottom of the booster sections were capped with a cardboard circle. Additional nosecones had their shoulders cut off and after sanding, were hot glued into a hole punched into the bottom of the boosters. White putty was applied and sanded around all joints. Booster rockets were glued to the sustainer such that the end of the rocket nozzles were even with the end of the engine hook. A 4 foot length of .25" Elastic cord was utilized as a shock cord and mounted inside the payload fairing using a piece of slotted cereal box cardboard. A 36" plastic Estes parachute with swivel was attached to the nosecone. The rocket was primed, sanded numerous times followed by paint and detailing using adhesive gold mylar, auto detailing stripes, and a label maker machine. Two coats of future floor wax were followed by automobile paste wax. |

Flight Report:

The Atlas 606 flew for the first time on the evening of December 14, 2001. It's completed weight (minus engine) was 8.30 ounces. It's CP as calculated by VCP was 4 inches in front of the end of the engine tube. This model's CG (with engine installed) was a little less than 8 inches in front of the end of the engine tube giving it an ample margin of stability. Using an Estes D12-3 engine and plenty of flame-proof wadding, the Atlas 606 lifted off the pad with a majestic roar with just a tad of weathercocking into the slight breeze. wRASP calculated its altitude at ejection to be around 265 ft but it seemed to fly higher than that. Its 36 inch parachute opened without incident and floated the rocket down slowly enough for me to be able to snatch it out of the air before it hit the ground. There was no scorching of the fin structure which was a concern I had prior to the flight and absolutely no damage to the rocket itself. This rocket will probably never be flown again as I am presenting it as a Christmas present to my sister who works as an attorney for International Launch Services. I am varnishing a wood plaque for a base and it will stand proudly as a desk model in her office. |

|

|