(Contributed - by Norman Dziedzic)

The "FAO Schwarzkopf" Model Rocket

Photo by Marty Schrader

|

...Yes, it really is a rocket!

Anyone who has attended a NIRA (Northern Illinois Rocketry

Association) launch knows that all sorts of things can be made into rockets:

- McDonald's Happy Meals

- Pringles Cans

- Large Dice and/or Star Trek Borg Cubes

- John Handcock Buildings

- Drink Cups

- Wiffle Bats

- Etc...

Since joining NIRA I guess you could say I've caught the Odd-Roc bug and bad. This is the affliction which makes

you look at everything in the universe as a potential rocket. Last Christmas, when strolling through the local Ace

Hardware I had a major Odd-Roc attack and just had to have the Toy Soldier lawn ornament to turn into a rocket. Sure

the Noel Candle lawn ornament was a more traditional rocket shape but when it comes to this disease, the odder the

better! |

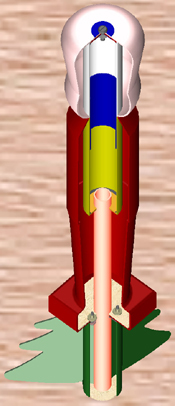

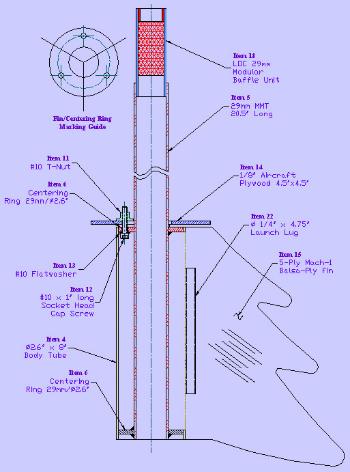

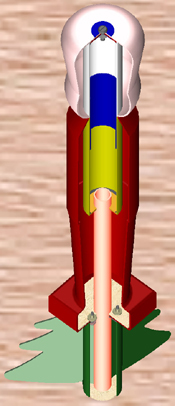

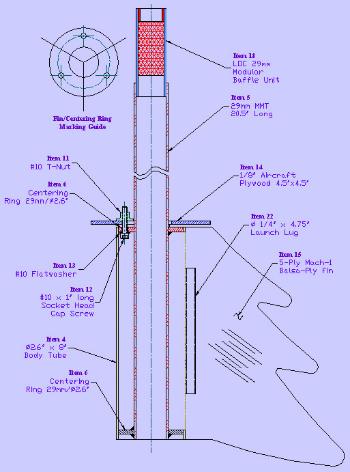

Image created in

Solid Edge by Unigraphics |

Design Details:

|

Height:

|

|

39.1 in |

|

Weight (no motor):

|

|

34.2 oz. Ready to Fly |

|

Max. Diameter:

|

|

5.5 in |

|

Motor Mount:

|

|

29mm |

|

Recovery:

|

|

45" Top Flight Parasheet |

The Toy Soldier Lawn Ornament

The Toy Soldier used in the FAO Schwartzkopf has a neck which just happens to accept a 2.6" BT with only

minimal sanding ans so is ideal for an Odd-Roc. As mentioned on the first page it was purchased at an Ace Hardware

store so if they have a common supplier for the country, it should be readily available around Christmas and discounted

for a short while after. There are many sizes of these toy soldiers so other size models are possible. This particular

soldier came with a light that plugs into a hole at the back of the neck. I just discarded it.

Although the FAO Schwartzkopf is very non-traditional on the outside, inside it is mostly your basic LMR to light

HPR construction. The only difference is in the final assembly where the rocketry components are attached to the

plastic body of the toy soldier.

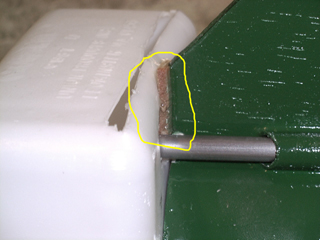

The plastic used in creating these outdoor beauties is some form of Polyethlyene (PE) to which almost no adhesive

will stick (I have found adhesives for gluing PE to more PE but not for PE to wood or paper). Some modelers have

claimed some success using hot melt glue or silicon calk with PE but there were going to be so many other variables in

this design I opted for assembly methods which didn't rely on gluing anything to the plastic body.

Separating the Head from the body:

To separate the soldier head from the body, I used a hack saw with a metal cutting blade. I slowly cut at the

smallest diameter of the neck checking often at the front and back to make sure I was making a straight cut. This is

best done in a garage or outside as it will generate a lot of plastic "fuzz" which contains static and sticks

to everything!

FAO Schwartzkopf Parts List

|

Item

|

Qty.

|

Description |

|

|

1

|

1

|

Plastic Toy Soldier Lawn Ornament |

|

2

|

1

|

BT 2.6" x 8" (For inside Soldier Head) |

|

3

|

1

|

BT 2.6" x 10.5" (For inside Soldier Body) |

|

4

|

1

|

BT 2.6" x 8" (For Christmas-tree Fin Can) |

|

5

|

1

|

MMT 29mm x 20.5" |

|

6

|

3

|

Centering Ring 29mm / 2.6" |

|

7

|

1

|

Bulkhead 2.6" |

|

8

|

2

|

5/16" Fender Washer |

|

9

|

1

|

5/16" x 1" Machine Screw |

|

10

|

1

|

5/16 Nut |

|

11

|

3

|

#10 T-Nut |

|

12

|

3

|

#10 x 1" long Socket Head Cap Screw (or Hex Head Screw) |

|

13

|

3

|

#10 Flat Washer |

|

14

|

1

|

1/8" Aircraft Plywood Backup Plate (4" x 4") |

|

15

|

3

|

5-Ply Balsa-Ply Fin |

|

16

|

2 ft.

|

Braided Nylon for "LOC" Style Shock Cord Mounts |

|

17

|

6 ft.

|

3/8" Heavy Duty Elastic Shock Cord |

|

18

|

1

|

LOC Modular Baffle Unit for 29mm MMT (Optional) |

|

19

|

1

|

2.6" Tube Coupler |

|

20

|

1

|

45" Round Top Flight Parachute |

|

21

|

1

|

Heavy Duty Snap Swivel |

|

22

|

2

|

1/4" Dia. x 4.75" Long Phenolic Launch Lug |

Construction of the FAO Schwartzkopf

Soldier Head Construction

- If you haven't already done so, go back to the initial construction page and follow the instructions for

separating the soldier head from the rest of the body.

- Drill a 3/8" diameter in the center of the 2.6" Bulkhead (Item 7)

- Epoxy the 2.6" bulkhead (Item 7) flush with one end of the 2.6" Body Tube (Item 2). Apply a generous

epoxy fillet to the inside corner where these items meet.

- Using approximately 1 ft. of the braided nylon cord (Item 16), make a "LOC Style" shock cord mount

and epoxy into the body tube (Item 2). Important: make sure the mount is at least 2.5" into the tube to allow

clearance for the shoulder interface with the body. Also, keep the loop of the mount within the body tube to avoid

zippering of the tube.

- Fit the body tube/Bulkhead assembly in the soldier head. You will need to trim/sand the opening in the bottom

of the head so that the tube fits "just snug" in the hole. The body tube should protrude down from the

opening approximately 1/8" when fully inserted in the head..

- Align tube within the head so that the bulkhead side is centered in the top of the head and mark the location

for the hole in the top of the head. The plastic is translucent and shining a light up from the bottom will let you see

the location of the hole already in the bulkhead plate. Using a hobby knife or drill, cut a 3/8" diameter hole in

soldier head at the mark.

- Glue the 5/16 nut (Item 10) to one of the Fender Washers (Item 8) with CA and hit with accelerator to

completely dry. Place this nut/washer into a socket with a long extension and insert into the head tube. From the

outside, insert the Machine Screw (Item 9) through a Fender Washer (Item 8) and tighten assembly together. Check that

the Body Tube is centered in the head; if required, adjust the hole in the top of the hat.

- Once the proper hole size/location is set, disassemble, paint the outside Fender Washer and Machine Screw

white to match the head and re-assemble. Paint the bottom few inches of the Body Tube red to match the soldier neck.

- When all the paint is dry, reassemble as above.

|

|

Soldier Body Construction

- If you haven't already done so, go back to the initial construction page and follow the instructions for

separating the soldier head from the rest of the body.

- Fit the 2.6" body tube (Item 3) into the hole in the top of the soldier body (Item 1) by trimming with a

hobby knife and sanding. This fit should be fairly snug as no no adhesive will be used here.

- Epoxy the tube coupler (Item 19) to one end of the body tube (Item 3) leaving 2.0" extending from the top

of the tube.

- Wick thin CA into the exposed end of the coupling to strengthen it since this will provide the link to the

Head.

- Using approximately 1 ft. of the braided nylon cord (Item 16), make a "LOC Style" shock cord mount

and epoxy into the coupler (Item 19). Keep the loop of the mount within the coupler to avoid zippering of the tube.

- Epoxy one of the centering rings (Item 6) flush with the bottom of the body tube (Item 3). This end is

opposite the one with the coupling.

- Using your favorite method, draw a straight line along the outside of the body tube. Epoxy one section of the

launch lug (Item 22) flush with the bottom of the body tube along the line.

- Locate the center of the bottom of the toy soldier (Item 1). With a rectangular or square base as is on my

soldier, this is accomplished by drawing two lines across the corners of the base. Where the lines meet is the center

of the area. Mark and cut a clearance hole for the 29mm motor mount tubing (Item 5). No need to be neat, it's just a

clearance hole but try not to get too big with it.

- On the square base of the toy soldier (Item 1), cut an access hole for the backing plate (See Final Assembly)

as shown in the second drawing to the right.

There are a few more clearance cuts to be made in the soldier body but these are best left until the

final assembly step.

|

|

Fin Unit Construction

- Assemble the LOC Modular Baffle Unit (Item 18) per the instructions which came with it.

- Using your favorite method, mark 3 equally spaced lines along the outside of the Body Tube (Item 4). To the

right of each of these lines, draw another line at the thickness of the fin. Across each of the double lines, make a

mark 1/4" from one end of the Body Tube (Item 4). Mark this same end TOP. Across each of the double lines, make a

mark 1/2" from the opposite (Bottom) end of the Body Tube (Item 4). These are the fin slots.

- Using a metal straight edge and hobby knife, cut out the fin slots. Work patiently and change blades often.

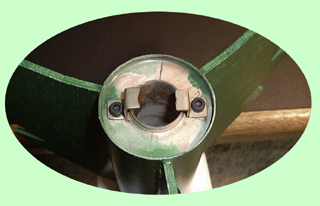

- On the centering ring (Item 6), mark 3 lines spaced 120° deg. apart (see figure at right) to denote the

fin locations. Mark one of the fin lines "REAR". Also, mark this side of the CR "TOP". Directly

in-between the fin lines, mark the center of the 3 holes as shown in the figure. Do not drill the holes yet!

- Mark one side of the 1/8" plywood Backup Plate (Item 14) "TOP" and mark one of the flat sides

of the Backup Plate "REAR". Find the center of this plate by drawing lines across diagonal corners. Place the

centering ring (Item 6) over the Backup Plate with both "TOP" sides up. The fin line marked "REAR"

should point directly at the rear side of the Backing Plate. Center the hole in the CR on the center mark of the Backup

Plate and clamp the two pieces together. Trace the 29 mm hole from the CR to the Backing Plate. With the

pieces still clamped together, drill three Ø7/32" holes at the marked locations.

- Cut out the 29 mm hole marked in the center of the Backing Plate (Item 14). Check the fit with the MMT (Item

5) it should be loose to allow for alignment in the final assembly.

- Take the Backing Plate (Item 14) and center it on the bottom of the Toy Soldier. Make sure

the TOP side of the Backing Plate is facing the head of the soldier and the side marked REAR is to the back of the Toy

Soldier. Now mark the locations of the three screw hols on the bottom of the Toy Soldier foot. These will be cut out in

the final assembly step.

- Epoxy the T-Nuts (Item 11) to the TOP side of the Backing Plate centered over the holes drilled in the

previous step. You can use the screws to make sure the T-Nuts are centered over the holes but do not glue the screws

into the T-Nuts.

- With the TOP side up, epoxy the CR with the holes in it flush with the top of the Body Tube (Item 4). Align

the fin lines on the CR with the slots in the Body Tube. Allow to fully dry before proceeding to the next stop.

- Epoxy the MMT (Item 5) to the CR/BT assembly from the previous step. The MMT should be flush with the bottom

of the Body Tube. Insert the last Centering Ring (Item 6) into the rear of the Body Tube to keep the MMT centered

during epoxy curing but do not glue the bottom CR at this time.

- Epoxy the Modular Baffle Unit (Item 18) to the top of the MMT (Item 5) as described in the Baffle Unit

instructions.

- Using the Fin Pattern, cut

the Christmas Tree Fins (Item 15) from the 5 Ply Mach-1 Balsa Ply stock noting the grain direction in the figure. Sand

all fins together to match the profiles. Due to the strange shape, I left my leading edges square. Test fit the Fins in

the slots and trim the fin tabs so the shoulders but up against the outside of the Body Tube and the tabs just touch

the MMT.

- Epoxy the Christmas Tree Fins (Item 15) to the BT/MMT assembly. Insert the last Centering Ring (Item 6) into

the rear of the Body Tube to keep the MMT centered during epoxy curing but do not glue the bottom CR at this

time. Apply epoxy fillets inside and out at all fin/tube junctions.

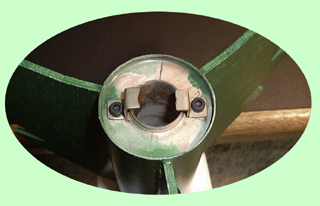

- If you will be using a positive motor retention system, make provisions in the rear Centering Ring (Item 6)

but do not glue the bottom CR at this time! (That will be done in the final step.

- Epoxy one of the launch lugs (Item 22) to the REAR Fin/Body Tube joint and fillet well.

|

Motor Retention "Klips" (optional)

|

The final assembly is the trickiest part of the the FAO Schwartzkopf. I will require a

little patience as you must do a good bit of test fitting that requires a few iterations of

assembly/dis-assembly/re-assembly. As with most model building, taking your time is paramount.

Most of the final assembly regards cutting clearances in the Toy Soldier body to allow for

screws and the launch rod. The body can be cut with a regular #11 hobby knife but you must be careful. It does take a

little extra "oomph" to get started, but then the blade move rather easily. Therefore, it best to cut away

from you so you don't run the blade into yourself. It is also easiest to make several short straight cuts rather than

trying to cut a curve into the plastic. Then you can go back and clean up the corners between the straight cuts.

You can also use a Dremel Tool to cut the plastic but you must be very careful as you can

cut very fast and things could get away from you (i.e. you can cut away more than you wanted to before you know it.

This method also generates a lot of very fine and full of static plastic shavings. Do this only in a garage or outdoors

where this type of mess is not a problem.

Final Assembly

- Double check the Alignment of the CR to Backing Plate: Use a T-Handle allen wrench (if Item 12 is a

socket head cap screw) or socket wrench with extension (if Item 12 is a hex head screw) to insert the Screws and

washers into the bottom of the fin can and to the T-Nuts in the backing plate (Make sure the fin marked REAR is in

alignment with the side of the Backing Plate marked REAR). If the screws don't line up with the T-nuts well, increase

the size of the holes in the CR with the next larger size drill (1/4"). Check again and if required open one or

more of the holes to accommodate.

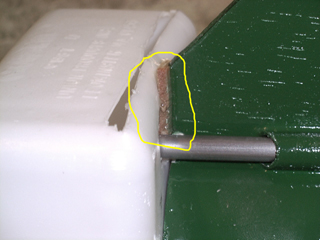

- Backing Plate Launch Rod Clearance: With the Backing Plate still assembled to the Fin Assembly, place a

1/4" rod up the launch lug and mark its outline on the Backing Plate. Cut out a clearance slot for the launch rod

in the Backing Plate. Cut this hole oversized for clearance.

- Slot the Toy Soldier Bottom for the Screws: Using the markings from Step 7 of the Fin Unit

Construction, cut slots out from the center 29mm opening around the markings as seen in Fig. A at the right. Due to the

un-even nature of the bottom of the Toy Soldier plastic mold, you may need to make these slots larger in a later step.

- Backing Plate Installation: Insert the backing plate (made in the Fin Unit Construction section) into

the slot in the bottom of the Toy Soldier foot. Make sure the side marked rear is point back as it will be hard to turn

once it is inside.

- Fin Assy. to Body Alignment: Slide the Toy Soldier Over the MMT of the Fin Assembly until it rests on

the top of the fin can. Starting with the hole at the front (the one you can't see) use a T-Handle allen wrench (if

Item 12 is a socket head cap screw) or socket wrench with extension (if Item 12 is a hex head screw) to insert the

Screws and washers into the bottom of the fin can, through the Toy Soldier bottom and into the T-Nuts in the backing

plate. If you cannot make the screws fit, you will need to expand the slots made in the previous step. Do not fully

tighten the screws yet.

- Fin Assy. Centering: Next, check that the Fin Assembly is centered on the bottom square of the Toy

Soldier. Again if you can't get the Fin Assembly to center, you will need to expand the slots made in step 1 above.

- Body Bottom Launch Rod Clearance: Insert a piece of 1/4" rod in the launch lug attached to the

rear fin until it touches the bottom of the Toy Soldier. Mark the outline of the rod on the Toy Soldier bottom. Cut out

the plastic for clearance around this mark.

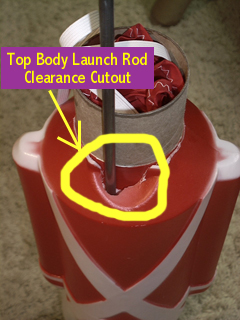

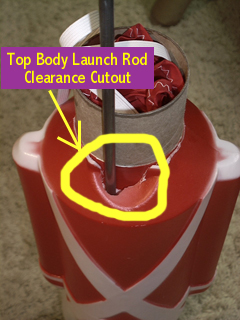

- Top Body Launch Rod Clearance: Now from the top of the body, sight the opening in the bottom and create

a cutout at the top for the launch rod as seen in Figure B.

- Launch Rod Clearance Lug Alignment: Now slide the body tube (Item 3) into the top of the Toy Soldier

Body until the top of the tube is flush with the top of the Toy Soldier Body as seen in Figure B. (The bottom CR should

go over the 29mm MMT of the Fin Assy. Insert a 1/4" launch rod through the bottom launch lug on the fin assembly

and the internal body launch lug. This rod will bind on the Toy Soldier's legs which must be trimmed as seen in Figure

C. Do not epoxy the Toy Soldier Body Tube in place yet!

- Launch Lug Alignment: Check that the launch rod inserted in the previous step moves freely through both

launch lugs. If not, the Fin Assembly is angled and needs to be shimmed into position as shown in Figure D at right.

Use scrap pieces of the aircraft plywood between the fin tops and Toy Soldier Bottom to pull the Fin Assembly into

allignment with the Body Tube.

- Soldier/Fin Attacment: With Everything aligned so the launch rod moves freely through both launch lugs,

Tighten the screws which go into the Backing Plate T-Nuts. From the open end of the Toy Soldier Body, drop some epoxy

or CyA adhesive onto the exposed threads of the capscrews to lock them in place. Next, with the launch rod in place,

epoxy the Toy Soldier Body Tube to the Fin Assembly MMT. Apply a generous fillet to this joint.

- Head Launch Rod Clearance: Place the Soldier Head on the Body Tube and mark and cut openings for the

launch rod as in previous steps.

- Shock Cord/'Chute: Tie the ends of the shock cord to the mounts in the Head and Body. Tie a loop in the

shock cord about 1.5 ft. from the head and attach the parachute to the loop with the heavy duty snap swivel.

- Balance: With the parachute installed but without a motor, the FAO Schwartzkopf balances at 18"

down from the flat of the head. This position works fine for the F62 Darkstar and G80 motors. For other motors, weight

may be required in the head. This can easily be accomplished by adding more fender washers under the hat.

|

Figure A. Toy Solider Bottom Slots

Figure B. Top Body Cutout

Figure C. Rear Cutout

Figure D. Fin Assembly Shim

|

Stability

Once you decide to build a model such as the Schwartzkopf at some point you have to ask

yourself, "Is this thing really going to fly?"

Based on a few previous experiences and several observations I have found the following to

be true:

- A rocket with a flat or near flat top is not inherently un-stable (a double negative, ok,

but you get the point)

- Flat (horizontal) surfaces near the rear of a rocket add a good deal of drag

stability

- When all else fails, the cardboard cutout method still isn't all that bad an analysis

tool.

So, to verify that I wasn't going to bury the poor toy soldiers head in the dirt I drew an

outline in Auto CAD and found the centroid which is the same as the cardboard cutout Cp. In the process I made a few

simplifications which were

- Leave off the arm protrusions

- Leave off the small hat visor.

- Assume there were 4 fins so I didn't have to draw one fin projected at 30 deg. to the

plane of the cardboard. (This I figured was a trade off with the horizontal surface shown at 10" in the figure

below).

What I got is shown here:

Then after thinking a little bit, I realized I could build up the model in RockSim (from

Apogee Components) if I just used a little Imagination and I came up with:

That said, I was confident that the FAO Schwartzkopf was headed fairly up. See the Flight Report for how reality

matched the science.

Flight Report

April 02, 2000

Greene Valley Forest Preserve

DuPage County, Illinois N.I.R.A. Special Launch (To beat the then impending insurance lapse date of

4/5/00)

The first flight of the FAO Schwartzkopf was on an F62-4 Darkstar motor with a simmed altitude of

355ft. Boy was I nervous with the rocket on the pad and all the still shots taken the LCO called for a head's up. He

gave the countdown and... major disappointment... nothing. One of the spectators had seen a clip fall off an igniter

lead so that was an easy recycle and away we went again..... The first flight of the FAO Schwartzkopf was on an F62-4 Darkstar motor with a simmed altitude of

355ft. Boy was I nervous with the rocket on the pad and all the still shots taken the LCO called for a head's up. He

gave the countdown and... major disappointment... nothing. One of the spectators had seen a clip fall off an igniter

lead so that was an easy recycle and away we went again.....

5 ... 4 ... 3 ... 2 ... 1 ... Launch and the Laser Fire

igniter immediately sent the Darkstar into overdrive! A roar hit the spectators as the pad was engulfed in thick black

smoke. It had to have been the straightest flight of the day and the crowd showed their appreciation with a few cheers

as the parachute unfulred right at apogee to bring the FAO Schwartzkopf safely back to earth.

The launch was a little too quick for my camerman but he did get the very impressive

Darkstar smoke trail from the maiden flight which is shown at right.

Photo by Rich Maryanski |

Photo by Rich Maryanski |

April 02, 2000 (at Same Launch as Above)

Greene Valley Forest Preserve

DuPage County, Illinois N.I.R.A. Special Launch (To beat the then impending insurance lapse date of

4/5/00)

With all the first flight gitters out of the way, I loaded the FAO Schwartzkopf with a G80-4 Fast White

Lightning to really wake up the neighbors. I had never seen one of these Fast White Lightning motors burn and all I can

say is WOW!

I ditched the Copperhead that came with the G80 and opted for another Laser Fire to fire the FAO Schwartzkopf

again and was not disappointed. This thing is like a White Lightning motor on steroids.

This flight simmed out to around 525ft. It didn't seem 175ft. higher than the first flight but deployment again

occured very near apogee for a textbook flight.

This time, the camerman would not loose the race and the results are seen in the photo at the left. Click image

for Higher Resolution.

|

The first flight of the FAO Schwartzkopf was on an F62-4 Darkstar motor with a simmed altitude of

355ft. Boy was I nervous with the rocket on the pad and all the still shots taken the LCO called for a head's up. He

gave the countdown and... major disappointment... nothing. One of the spectators had seen a clip fall off an igniter

lead so that was an easy recycle and away we went again.....

The first flight of the FAO Schwartzkopf was on an F62-4 Darkstar motor with a simmed altitude of

355ft. Boy was I nervous with the rocket on the pad and all the still shots taken the LCO called for a head's up. He

gave the countdown and... major disappointment... nothing. One of the spectators had seen a clip fall off an igniter

lead so that was an easy recycle and away we went again.....