| Manufacturer: | Scratch |

Home Improvement, The Rocket

Background

A few years ago, I started building a rocket called the Flying Dutch Boywhich was made from paint rollers for tubes and paint brushes for fins.At that time, I found out that the I.D. of a paint roller is just about 38mm (It's actually a little smaller).For this Descon, I wanted to expand on that theme and take it further to the whole Home Improvement genre.Besides most of the components being home improvement items, I also used Liquid nails for most of the assembly of Home Improvement. I chose a 29mm MMT because I figured the model would probably be heavy enough to require it.Given my previous knowledge of the I.D. of the paint rollers, I realized I could use 38mm-29mm centering rings for the motor mount if I peeled a layer or two off of the outside of each centering ring.Also, since it fit with the theme, I chose to include Donald Qualls' (a.k.a. The Silent Observer) U.M.R.S. (Universal Motor Retention System) as published in the July/August 1998 Sport Rocketry.This system uses PVC plumbing parts to retain 29mm (and 24mm w/ adapters) motors in to a rocket.I've wanted to try this for a while and Home Improvement was the perfect opportunity. Too bad one of the inspirations for the U.M.R.S., the DarkStar motors, have been discontinued.(I do have one F62-4 and two F62-6's stashed away... but I haven't decided if Home Improvement is the proper use for the -4 yet).

Parts List

|

|

|

Description |

|

|

|

Thick nap paint roller (Left over from any old house project) |

|

|

|

Blue Foam Paint Roller (Ok, I bought this from Home Depot) |

|

|

|

Almost Empty Liquid Nails Cartridge (Or other Cartridge Product) |

|

|

|

Saran Wrap Roll Core for making couplers |

|

|

|

2-1/2" Plastic Handle Paint Brushes (Cheapest you can find... and lightest) |

|

|

|

2-1/2" Plastic Scrapers (Cheapest you can find... and lightest) |

|

|

|

29mm Motor Mount Tube x 7.25" long. |

|

|

|

38mm to 29mm Centering Rings |

|

|

|

1/2" CPVC 90 Deg. Elbow Fittings |

|

|

|

2" wide Duct Tape (Is any home improvement job complete without it?) |

|

|

|

Parachute |

|

|

|

Schedule 80 PVC 1-1/4" x 2" Long Nipple |

|

|

|

Schedule 40 PVC 1-1/4" Cap |

|

|

|

Cardboard from back of legal pad or shirt packaging |

|

|

|

Shock cord material.(I used braided nylon para cord) |

Construction

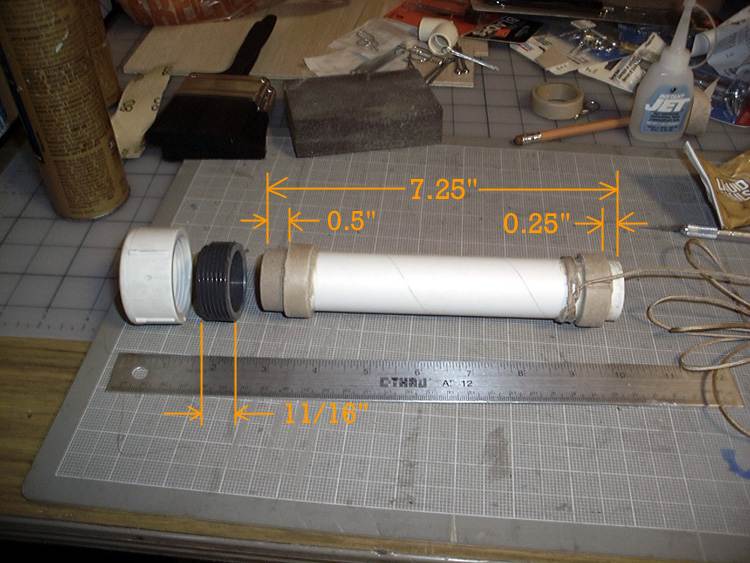

- U.R.M.S. components:You may want to read Don Qualls' excellent write up on this motor retention method at this link.To cut the nipple, I used the band saw at work with pretty good results.This can probably also be done with a hack saw and a steady hand or a miter saw (watch your fingers, this part is not very big!)You can make another U.R.M.S. with the other end.My nipple ended up to be just about 11/16" long.I drilled a 3/4" hole in the pipe cap but left off the AR2050 referenced in the U.R.M.S. article as my motor fit snug without it.

- Motor Mount:The motor mount is put together pretty much like you're average rocket except, being the Home Improvement Rocket, we use Liquid Nails for the assembly (See Adhesive note).The aft centering ring needs to be positioned according to how the PVC nipple was cut for the U.R.M.S. (step 1 above) such that when the nipple is butted up against the aft centering ring, the end of the motor mount tube will be recessed in the nipple about 3/16". For my setup, the nipple is 11/16" so subtracting 3/16" of recess leaves 1/2".So the aft centering ring is set up 1/2" on the motor mount tube.

- U.R.M.S. Nipple Shim: To provide a snug fit for the nipple on the motor mount tube, a cardboard shim is needed.I used a piece of cardboard from the back of a legal pad.Cut it 1/2" wide and just long enough to wrap around the tube.Since the fit was snug, I used wood glue here to prevent a thickness build up from the Liquid Nails.

- Shock Cord:I chose to mount my shock cord to the motor mount as shown in the figure.I simply notched the forward centering ring to allow the cord to get to the front of the motor mount and wrapped the cord around the motor mount tube several time using liquid nails to secure it in place.To keep the shock cord from getting glue on it in the following steps, fish the end of it back through the motor mount tube, bundle it up and keep it in the tube with a piece of masking tape.

- Motor Mount Installation:Using sandpaper, rough up the inside of the thick nap paint roller at the locations where the centering rings will sit within the tube.Using a dowel or similar device, apply your adhesive of choice in a ring about 6" into the aft end of the paint roller.Slide the forward end of the motor mount assembly into the roller but stop before touching the adhesive.Now apply a ring of adhesive just inside the aft end of the tube (You have to work around the motor mount tube).In one smooth motion, push the motor mount assembly into the tube until the aft end of the aft centering ring is flush with the aft end of the paint roller.Allow to dry.

- U.M.R.S. Nipple Attachment:As instructed at the U.M.R.S.

page, use thickened PVC cement to glue the nipple to the aft end of the

motor mount which is sticking out the back of the paint roller.Make

sure you butt the nipple against the aft centering ring.

- Coupler Construction:Make a coupler for the two paint rollers from the saran wrap roll.Cut a 3" section off of the roll. The tube is too big for the roller I.D.'s so you need to remove a lengthwise slice from the coupler.About 1/8" does it but check as you go to make sure.Once you have a good (slightly loose) fit in the paint rollers,glue the coupler together using some more cardboard as a backing on the inside part of the coupler.

- Coupler Assy: Rough up the I.D. of the paint roller.Apply your adhesive of choice to the inside of the front end of the paint roller and slide the coupler approx. 1.5" into the paint roller and allowed to dry.Once dry, rough up the I.D. of the end of the the blue foam roller, applyadhesive to the I.D. of the blue foam roller and slide it over the coupler butting it up against the paint roller.Make sure the tubes are aligned and straight.

Liquid Nails Tube Preparation:If not empty, use your caulk

gun and empty the contents of the liquid nails tube in a safe place/manner.

Cut off the rear metal ring on the tube.There will probably be some

left over smears of Liquid Nails on the inside of the tube.This

is all right except for the aft 3/4" where the Liquid nails tube will interface

with the blue foam roller.If necessary, sand the aft 3/4" of the

tube to remove any of this residue.

Liquid Nails Tube Preparation:If not empty, use your caulk

gun and empty the contents of the liquid nails tube in a safe place/manner.

Cut off the rear metal ring on the tube.There will probably be some

left over smears of Liquid Nails on the inside of the tube.This

is all right except for the aft 3/4" where the Liquid nails tube will interface

with the blue foam roller.If necessary, sand the aft 3/4" of the

tube to remove any of this residue.- Liquid Nails Tube Shock Cord Mount & Shoulder Stop:

Using the Saran wrap tube, construct two 3/4" thick rings as shown in the figure to fit inside the Liquid Nails tube.These must be fit individually to account for the Liquid Nails residue inside the tube.One will be recessed into the tube 2-1/4" and will be the shock cord mount. The other will be recessed into the tube 3/4" and will provide a shoulder stop when the Liquid Nails tube is slid over the blue foam roller. Tie one end of the shock cord around the shock cord mount ring.Glue this ring in the aft end of the Liquid Nails tube and recess about 2-1/4". Thread the shock cord through the shoulder ring and glue this ring into the aft end of the Liquid Nails tube and recess about 3/4". - Foam Roller Front Coupler:

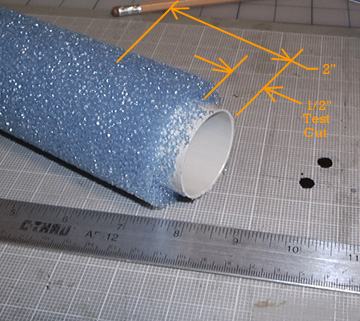

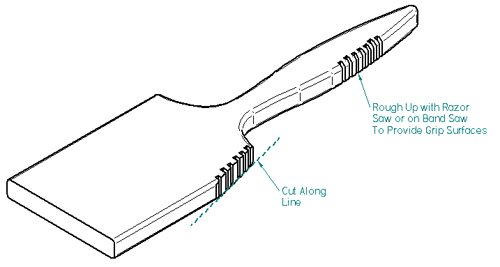

To provide a coupler for the top Liquid Nails tube to slide over the blue foam roller, we use none other than Duct Tape.First you need to remove the forward 2" of foam from the roller. Simply use your hobby knife to score a line around the tube at the 2" mark and you can peal off the foam.The image shows my first test cut of 1/2" and the a dimension for the full 2" which was eventually removed. Note: there is a small amount of foam which will not come off but that's not a big deal. Then build a surface by wrapping the duct tape around this 2" area until the Liquid Nails tube will just fit over it (Like the fit of a nose cone in a normal rocket). - Paint Brush Fins (2):To prepare the paint brush fins, cut off one corner as shown in figure and make a bunch of cuts on the surfaces to be glued so the glue has something to bite into.You will be aligning the end of the metal bristle retainer with the aft end of the paint roller (Refer to any full size picture of rocket in this page).Lay down nice size beads of Liquid Nails where the brush will contact the tube and press the brush into the tube.Make sure the brush is straight and true as you would a fin.You need to hold each brush in place for about a half hour or it will probably move on you.I couldn't figure out a quick way to clamp the irregular surface so I bit the bullet and waited it out.Full cure will of the Liquid Nails will take a couple days.

- Plastic Scraper Fins (2):Ok, this is kind of a cop out but you install the plastic scraper fins just like the paint brushes except you don't need to cut a flat surface on them.

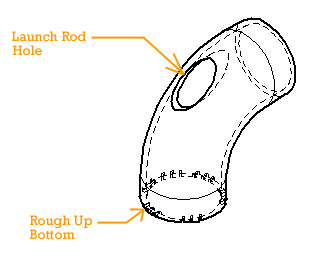

- CPVC Elbow Launch Lugs:

To Prepare the elbows for use as launch lugs.Drill a 5/16" Hole parallel to one leg of the elbow and as far up as you can.Then rough up the bottom using a razor saw or band saw so the glue has something to bite into.In-between a Paint Brush and Plastic Scraper, attach the launch lugs by applying a liberal bead of glue around the roughed up end and holding in place for about 30 minutes.These I was able to clamp into position with quick clamps. Point the elbows at each other as shown below and make sure the launch rod holes line up before the glue sets up. - Miscellaneous Final Assembly:

All that's left is to tie the two shock cords together and provide a chute of some sort.I was going to use some old plastic tarp that I used to cover a pile of wood last winter but time constraints prevented me from that so I recycled my parachute from another "flounder" model the Quaker Oat Boy.The ideal wadding would be cellulose insulation but I didn't have any of that either so a heat shield from Prat Hobbies was what I used. - To prep the U.M.R.S. Wrap some 3/4" masking tape around the aft end of the motor to create a thrust collar.Then just slip the motor into the mount and tighten the PVC cap.Don't tighten too much or you may not be able to get it off.Much more info is at Don Qualls' site on the U.M.R.S.

Flight Report

The

initial flight of Home Improvement, The Rocket was on May 13, 2001.

The skies were clear and the wind was a calm 3-5 MPH.I had tried

to fudge the fins into RockSim to check stability but didn't really know

how to handle the bristles of the brushes.I took a swag and eye-balled

some dimensions into the program and got a Cp around 24" back from the

tip of the Liquid Nails cartridge.The motor used was an Econojet

F20-4W which seemed about right for the weight.To try to account

for the fuzzy surfaces, I played around with drag coefficient values from

.8 to 1.5 which gave me ideal delay times of 4.5 sec to 3.5 sec so I was

in the ballpark.

The

initial flight of Home Improvement, The Rocket was on May 13, 2001.

The skies were clear and the wind was a calm 3-5 MPH.I had tried

to fudge the fins into RockSim to check stability but didn't really know

how to handle the bristles of the brushes.I took a swag and eye-balled

some dimensions into the program and got a Cp around 24" back from the

tip of the Liquid Nails cartridge.The motor used was an Econojet

F20-4W which seemed about right for the weight.To try to account

for the fuzzy surfaces, I played around with drag coefficient values from

.8 to 1.5 which gave me ideal delay times of 4.5 sec to 3.5 sec so I was

in the ballpark.

The center of gravity seemed a little far back by the "feel" method but time was a-wasting and I knew I wasn't that far off from what it should be.The field was big enough and empty so I couldn't do too much damage anyway :-)A quick 5 count and a little chuff and WHAM, the F20 burped to life.Unfortunately, at around 40 ft. things got real unstable and Home Improvement, The Rocket did a couple loops and acrobatic moves before free falling from maybe a total of 60 ft.Ejection happened about a half second after touch down.:-( ... I guess the "feel" method isn't always that bad after all...We missed a picture of the launch but here is one of Home Improvement, The Rocket just before crasing back to earth(You can also see some of the smoke from the lift off in the image).

The only damage was that one of the launch lug elbows had gotten very loose.It was a little loose to begin with but with all that glue impregnated into the paint roller "fur" I didn't think it would come off. Since the beginning of the flight seemed stable, I don't think this contributed significantly to the crash.

For the next flight attempt, I will add some nose weight and take a little more time to get the fins approximated in RockSim.My plan here is to ignore the bristles of the paint brushes altogether.Then find the average center of area and area of the combined Plastic Scrapers and Paint Brush handles and use these to draw in a fins set.How do you add nose weight to The Home Improvement Rocket? You find a hand full of old hardware and foam it into the nose with Great Stuff of course!

|

|