| Manufacturer: | Scratch |

(Contributed - by Bill Westfield)

|

|

||||

|

||||

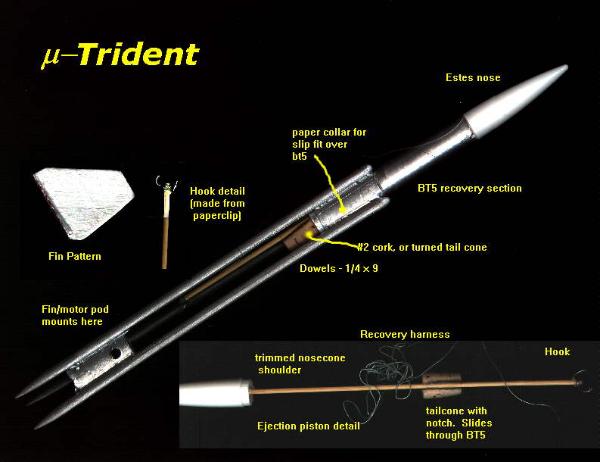

| This model looks like an Estes Trident downscale, about a 1/2 scale, at

first glance. It uses BT5 for the motor and "passenger" compartments,

and 1/4 inch dowels for the duct tubes. Obviously, dowels are not tubes, and

1/4 inch tubes would probably not be adequate for ducting ejection gasses

anyway, so another scheme is used for ejection the parachute. The bottom

tailcone (which is a small cork in the prototype) and forward nosecone of the

passenger section are both mounted on a thin dowel (bamboo skewer), so that the

assembly can slide entirely out of the forward section of body tube. The dowel

extends past the tailcone and ends in a hook. When in launching position, a

rubber band(s) is looped over the duct pods and engages the hook, and a small

burn string is threaded through the exhaust ports in the motor pod to hold the

assembly in place until motor ejection. The ORIGINAL Trident, which had three BT-5 sized ejection ducts. Later, there was the "Trident-2" or somesuch, which only had two pods of BT20 and is sometimes insultingly called the "bident." The u-Trident is a downscale of this original three tube trident, with a twist. Fins are attached in between the duct pods rather than ON them (for a stronger joint.) Small tubes were fashioned that are a slip fit OVER the BT5, and the duct pods were fastened to this rather than direct to the body tubes. This allows easier construction, as well as clearing any over-diameter of the nose cones. Both nosecones are missing their base, and the forward nosecone has the shoulder trimmed as well to make more room for the recoevry system. The ejection ducts are actually drilled THROUGH the shoulder of the motor pod nose, to make for greater strength there. |

||||

|

|

||||

|

||||

|

||||

All images and designs are protected by the author's copyright |

||||

| uTrident Flight Report. First, the choice of recovery system is a bit critical. There's only about three inches of BT5 tubing for it to fit it, and it has to fit loosely enough to be deployed by rubber bands. I made an eight inch (8") parachute from a grocery produce bag (of the thin, MDPE variety, I think. Thin and rather soft. 1/4 mil mylar might work fine too.) Pre-flight prep is a pain with this model, a bit worse than the average model that uses a burn-string. The piston is inserted partway into the recovery bay, and then the chute is folded and wraped a couple times with its shrouds to keep it folded. Then you insert the chute over the bottom of the piston, followed by all the shock cord and additional shroud lines, trying not to get them tangled about the piston's dowel. I used a piece of larger dowel to push them in (lightly.) Finish insterting the piston and seat the nosecone. Now, thread the burn string (a piece of dental floss worked well - strong but with a low melting point) through two of the exhaust ports and knot it tightly on the piston's hook. (if you learned any fancy knots, you may have a chance to use them. You want something that can be tightened, but won't loosen on its own.) Finally, attach the rubberbands. I used a #16 rubber band, knotted in the middle - the knot engaged the hook, and the two ends looped over two of the "pod" ends. Don't position the rubberband in a way that it will block the launch lugs. (note that the rubberband is disposable used this way.) Hopefully the tension of the rubberband won't push the nosecone back out (when your burn string knot wasn't tight enough. Note - perhaps a longer nosecone shoulder would help with this!) Insert motor. Use an external tape thrust ring, and enough tape so that the motor probably won't be kicked out. (Unlike most parachute models, this is more esthetic than important. Even if the motor ejects, the burn string will probably be burnt through!) It's a relatively heavy model for it's size, so I picked an A10-3 for the Launch. This sent it up a good distance, straight and true. The recovery system deployed successfully and the rocket recovered fine, drifting a "typical" distance and landing on the parking lot (the eight inch chute seemed to be just about right.) Upon recovery I noted that the piston had fully deployed, as it was supposed to. Pretty much a perfect flight! |

|

|