Giant Leap Rocketry Aerospace Composite Fins

Giant Leap Rocketry - Aerospace Composite Fins

Contributed by Dick Stafford

| Manufacturer: | Giant Leap Rocketry  |

Brief:

This is a review of Giant Leap Rocketry's 'Aerospace Composite' fins. These

fins are offered in 1/8, ¼, ½, and 3/8 inch thicknesses and in 15

pre-defined shapes. If you want to cut your own, you can also buy the raw

stock. Giant Leap describes their composite fins as follows: "Giant

Leap Rocketry now offers the ultimate in fin material. This aerospace composite

material is used in advanced aircraft. It is much stronger than wood, more

rigid than G-10 (for equivalent thickness). Lighter than wood, 1/3 the weight

of G-10." The material itself consists of "An inner layer of

NOMEX(TM) honeycomb, sandwiched between either thin G-10 Fiberglass or Carbon

Fiber!"

Construction:

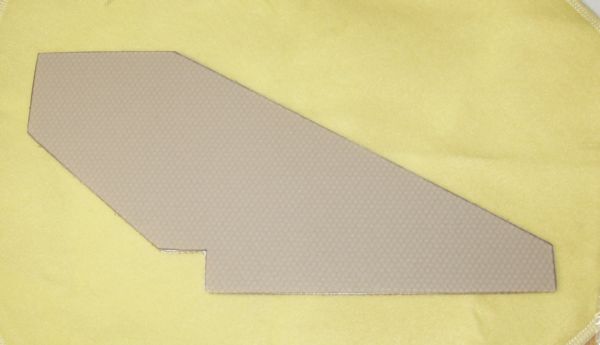

My fins are 1/8" thick in style #8. Referring to the first photo, the root

edge along the fin tab is 7.375", the span (not including the fin tab) is

4.875", and the overall length is 11.625". You specify the

thru-the-wall tab by identifying your body and motor tubes. Mine have tabs for

a 3" tube and a 29mm motor mount.

The first thing I noticed about the fins is how light they are! I can't vouch for Giant Leap's numbers, but here are my qualitative impressions. To me they seem as light as 1/8" balsa and as rigid as 3/32" G10. I don't have equivalent fins in these materials to weigh and bend, but these are my guesses. They would even be more rigid if framed in a hardwood dowel.

You can see the honeycomb structure in the next photo. The outer layers of fiberglass are very thin, probably thinner than 1/64", and if you look back at the first photo you can clearly see the honeycomb pattern through the G10.

Giant Leap suggests that you epoxy a dowel, hardwood strip, or even a G10 strip to the edges of the fin. This will hide the rough edges and will strengthen the fins. It seems that I always have to do something different, and this is no exception. For the leading edge, I attached a 1/8"x1/8" balsa strip with PerfectGlue Type 2 (similar to thick CA). This was easy to sand to a smooth shape. For the other outer edges, I filled the exposed honeycomb with Fill-n-Finish. Since Nomex® doesn't cut neatly, there were exposed fuzzy things hanging out all over. I soaked the edges in PerfectGlue to harden them, sanded them down, and refilled them. My one worry is a bit of flexing will pop the balsa off, but only time will tell. The next photo shows the framed fin mounted to a body tube.

When mounting the fins, one problem became evident. The fin tab in the front is 1/8" longer than in the back. At first, I thought I would simply have to trim the short section of the fin overhang immediately behind the tab. However, it turned out that this depth was correct for the tubes I was going to use, so I would also have had to trim the entire tab. Another possible fix would have been to extend the frame 1/8" further down. This would have left a small gap in the root tip that would have been easily filled. Unfortunately, I figured this out after I had finished. The good news is that the gaps were easily plugged with small pieces of the balsa I used to frame the leading edge.

So, that's it for now. This review is of the stand-alone fins. I'll follow up with a review of the rocket, and will note how the fins hold up. The basic material warrants full rating of '5'. Despite the fact that I easily remedied the fin tab issue, I will have to deduct a point from my rating, moving the rating to a '4'. In my experience, this is not typical for Giant Leap's work and I hope this was an isolated incident.

Summary:

This material is a bit pricy, but if you want tough, light fins, I

think you will be impressed. If anyone else has used these fins, please add a

comment. I'd really like to hear how easy it is to cut the raw material.

Oh, and you may see that I bumped the overall rating up by half a point, just for the 'cool factor'. I am now thinking that I won't paint the fins so the honeycomb pattern remains visible.

Overall Rating: 4 out of 5

|

|

|

|

K.C. (November 2, 2008)