| Construction Rating: | starstarstarstar_borderstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2010-01-19 |

| Manufacturer: | Hostile Projectiles  |

Brief:

This is a sport scale BT-60 V-2 that flies on 18mm motors. The main thing that differentiates this kit is the

hand-cast resin nose and tail cones. These are not your daddy's resin cones. They are thin walled and not much heavier

than solid balsa (if at all). The initial flight reports indicate are that they are also tough. The detail is really

makes them stand out. The nose sports hatches, including the rivets. The tail includes preformed fin fairings with

slots for the balsa fins and the turbine exhausts.

Construction:

Parts provided:

- Resin boat tail and nosecone.

- A section of BT-60 body tube.

- An 18mm motor mount.

- An engine block and spring clip.

- Two centering rings.

- A snap swivel.

- A screw eye.

- An elastic shock cord.

- A trash bag parachute, with string and tape tabs.

- A piece of styrene to mount the eye screw to the nosecone.

- One sheet of 9x4x1/8 balsa.

- Templates for the fins.

- Half-round styrene for fin detail (missing from my kit).

- An instruction CD.

Parts I added:

- Steel fishing leader to extend the provided shock cord.

- Lead shot and epoxy nose weight.

- Larger lug

- An 12" nylon 'chute

This kit is called a 'garage kit' aka a 'builders kit'. There is no header card or print instructions. The latter

comes on CD an includes the instructions in both .doc and .pdf formats, a copy of the fin template, and a graphic that

you can use to make decals. The instructions are not polished but are written in a humorous manner, which made the kit

all the more entertaining.

The parts other than the nose and tail cones are fairly typical. The tubes are not a cleanly cut as some others, there are no laser cut fins, and the 'chute is plain trash bag plastic.

Construction starts with prepping the nose and tail cones. You have to wash them and scrub them lightly with steel wool to remove the mold release. These are hand cast and the instructions warns of minor flaws. The finish on mine was great and the only flaws are two small voids on one V-2 fin flaring. Once cleaned, you are told to prime them, but I waited until the other parts were started.

A lot of the instructions are dedicated to fin prep. You are supposed attach the provided template to the fin

stock using 3M '77" spray-on adhesive, cut them out, and peel the paper back off. I must have used too much

adhesive because the paper didn't want to come off the balsa. Instead, I decided to leave them laminated and printed a

second copy for the flip side. I sealed the edges of the laminations with thin CA. Then comes the cool part - you etch

the fin panel lines in using the provided templates and a ball point pen. Wait, my templates are already attached. The

template file on the CD is appropriately entitled: “You screwed up.” I laughed at that one...and resemble

that remark. Despite this minor 'oops' the etching seems to have worked out well. The plus is the fins will be stronger

and the negative is a tiny amount of weight is added to the business end.

Once everything is primed, the fins are glued into their slots using 5-minute epoxy. This part made me smile - the slots in the tail cone ensure the fins are instantly and perfectly aligned.

Since the cone is hollow, You CA or epoxy a styrene tube to the cone's wall and screw the eye to that. I opted for epoxy, which was mixed with the fin batch.

Next up in the instructions is the motor mount (actually, I did this in parallel with the previous steps). This

includes the typical spring hook, motor block, and 2 centering rings. A small cardboard ring is mounted on the base and

the ply ring on the top. You are instructed to ream the base of the tail cone to fit the small ring and the top

shoulder to fit the ply ring. For the tail ring, I wasn't comfortable grinding the base to fit the BT-50 sized ring so

I ground a little and peeled a little. For the upper ring, I preferred to grind plywood rather than resin, although I

did rough up the interior of the cone.

I also mounted a stainless steel fishing leader through the top ring. This replaces the specified tri-fold mount and will keep the elastic shock cord even further from the hot ejection gasses. If you do this, make sure you add a small fold of duct tape, or equivalent, to the point there the extended wire hits the body. Finally, the mount is attached to the tail cone using 5-minute epoxy.

I didn't build the supplied 'chute and will use a nylon one that I have in the ol' range box. The stock 'chute should build like the Questes ones.

The final issue is stability. The instructions say to balance, make a cardboard cut-out, and do a swing test. I opted to make a RockSim model. Mine should be slightly heavier than stock considering the fin laminations, lots of epoxy on the top CR, the steel leader and the nylon 'chute. It came in at 3.25 oz. Based on RockSim, I found adding a bit over and ounce of nose weight should make it stable on an AT reload. Well, I measured the weight and then added the epoxy above that. I had a brain fart when looking at the thrust to weight ratio and had thought the result would fly well on a C6. Well, it now won't so I'll be flying this on reloads only. Two 1/8" lugs are provided, however, I upgraded to a larger one.

Finishing:

Finishing:

All-in-all, there is a lot of finishing tips provided for this little rocket. To stay in line with the current

headlines, I 'went rogue', deviating quite a bit from the instructions. I substituted Fill'n'Finish and Testor's putty

for the fillers specified and red Rustoleum primer for the specified Tamiya primer.

The main tips I followed is prepping the cone and using the etching technique to provide fin details as noted above. The instructions say to sand down the slight warping on the nose cone hatches. Personally, I like the 'drunken builder' effect seen on many of the real V-2 rounds.

The final fin trim is the servo pods near the tip of the fins. These were supposed to be half-round styrene. This was no where to be found in my box but scrap balsa was easily substituted.

Despite having scrubbed what I thought was a lot and then some more, the Rustoleum primer bubbled badly in one quadrant of the tail cone and a tiny bit on one area on the nose. I guess I didn't scrub uniformly. I waited a full day and then sanded these areas along with the rough spots. The tail cone sanded well but the primer came of the bottom of the nose. I took the opportunity to sand this bare area a lot. The second coat covered well.

I chose the red primer to provide part of the camo scheme. And added some Rustoleum camo colors over that.

Construction Rating: 3 out of 5

Flight:

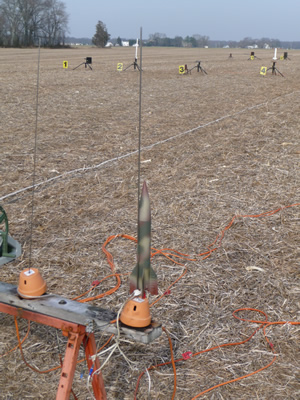

I chose the D13-7 for the V-2's maiden voyage. I first loaded some dog barf to fill the space in the tail cone and

then some Quest wadding wrapped around more dog barf. The steel leader was laid over this, followed by an 12"

nylon 'chute. The ground was soft so I thought this would be sufficient.

The boost was fast and straight.

Recovery:

Ejection was a little late but I didn't count the seconds to see whether it was a bonus delay or inherently just too

long. Recovery was perfect.

Flight Rating: 5 out of 5

Summary:

The main plus of this kit is the totally cool nose and tail cones. These alone make the kit worth the cost, which is

comparable to a BT-60 V-2 kit from Aerospace Specialty Products. Aside from aesthetics, the pre-formed slots make fin

attachment easy and sturdy. The other plus is the simple method of scoring the fins to provide panel details. The

minuses is that the other components aren't as 'clean' as some other manufacturers, you really need to think about

parts fit as you go, and stability has to be addressed. Most of this is easy but there is extra room for operator

error.

Overall Rating: 4 out of 5

|

|

Flights

|

|