| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2010-12-01 |

| Diameter: | 2.60 inches |

| Manufacturer: | The Launch Pad  |

| Skill Level: | 3 |

| Style: | Scale |

Brief:

Brief:

The Launch Pad HARM kit is an accurate, near-1/3rd-scale, version of the U.S. Armed Forces HARM AGM-88A air to ground anti-radar missile. It can be launched on a wide variety of both single use and RMS motors from D-F.

Construction:

The kit arrived in a plastic bag, similar to some Estes or Quest kits and consisted of two BT80 2.6" body tubes with the coupler stored inside one of the tubes , three sheets of balsa for the fins, a plastic nose cone, paper templates for the fins and boat tail, an 18"x 30" mylar parachute, motor mount with 1.5" boat tail tube, shock cord and instructions! What really impressed me were the laser cut motor mounts, which appear to be much stiffer and stronger than Estes mounts. Another nice touch was the swivel link system for the parachute. About the only items lacking in the kit were a set of decals and fin guides, but anyone who has a few kits under their belt can easily handle the assembly. Included in this review are some tips on making scale decals for this model and I will be happy to supply anyone with the templates. Component Rating: 5 of 5

Construction: There are six pages of instructions supplied with the model which take your through the building and finishing process. If you are at all familiar with the Launch Pad kits, you will note that many of them have you "build" a custom nose cone. You will be happy to hear this was not necessary with the HARM kit as it comes complete with a BT80 ogive nosecone that only requires some clay weight. Weight was added to the nose cone as my first step and epoxy was poured in to help seal the clay in place.

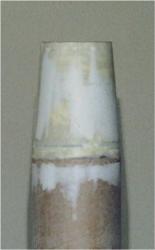

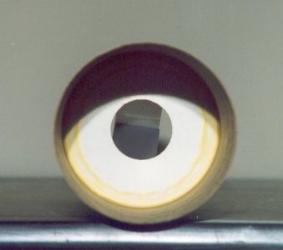

The next step was the assembly of the motor mount. Some of you may have wished you had the nose cone to build rather than the motor mount/boat tail assembly after reading this section. It was not a difficult process but their pre-measured boat tail card stock was a bit off in size. They have you build the motor mount using 1 ½ " centering rings that eventually fit into an "inside" body tube. Once the mount is glued in to this 1 ½" tube, you then glue centering rings on the outside of the smaller body tube so it can be mounted inside the BT80 main body tube. The purpose of the "tube within a tube" is that you have to make a boat tail that narrows from the BT80 main tube to the tail cone 1 ½" inside tube diameter. A paper template is supplied to wrap around this area (see pics for details) but the paper measurements are too big. When you cut the boat tail assembly out from the supplied stock on the drawn lines, it is too large at the top/BT80 side. I had to do some fitting to get mine correct and this is what took a while.

Once the boat tail was on, I did coat it on the inside with thin CyA. The outer assembly was filled with Evercoat Filler, then completely encased in epoxy. I also painted the inside of the exhaust tube with epoxy, as I have seen some Launch pad kits scorch this area during launch.

Once the boat tail was on, I did coat it on the inside with thin CyA. The outer assembly was filled with Evercoat Filler, then completely encased in epoxy. I also painted the inside of the exhaust tube with epoxy, as I have seen some Launch pad kits scorch this area during launch.

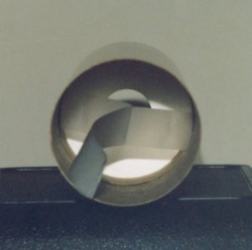

The rest of the assembly was straight forward; Alphaetic resin and medium CyA was used for assembling the rest of the model. Before gluing the body tubes together with the supplied coupler, you should mount the bulkhead plate in the forward body tube. It's easier to reach before full assembly but the hard part was getting the bulkhead to sit correctly while it was recessed 7" inside the tube. To make this assembly easier, I used the supplied tube coupler with scotch tape on the sides and connected at the center for a removal handle, then slid the coupler in place until one end was 7" below the upper body tube edge. The bulkhead was simply dropped in, then tacked inside the tube with resin. The coupler made sure the bulkhead was positioned perfectly, then once the glue set, I pulled the coupler out from the rear using the Scotch Tape handles from the previous note. See pics for details.

The tubing coupler was glued in next and I could now get a good perspective of the size of this model. I noticed the instructions did not tell you to fill and sand the joint where the two body tubes are glued, so make sure you do this prior to mounting the center fins.

Fins were glued on next using CyA and are surface mounted. I decided to taper the leading edge of each lower and center fin for scale appearance. Afterwards, I opted to fiberglass both the lower and center fins on for stiffening and additional strength using ¾ ounce fiberglass cloth and 30 minute epoxy. I had read of instances where people saw the surface mounting technique lacking in strength and I didn't want this to become an issue. If you don't fiberglass, make sure you use thin CyA to stiffen the soft balsa fins prior to gluing them on.

Fins were glued on next using CyA and are surface mounted. I decided to taper the leading edge of each lower and center fin for scale appearance. Afterwards, I opted to fiberglass both the lower and center fins on for stiffening and additional strength using ¾ ounce fiberglass cloth and 30 minute epoxy. I had read of instances where people saw the surface mounting technique lacking in strength and I didn't want this to become an issue. If you don't fiberglass, make sure you use thin CyA to stiffen the soft balsa fins prior to gluing them on.

Location of the launch lug was not specified, which is normal for these kits. I cut mine in half, gluing one piece on with it's bottom just above the tapered edge of the boat tail and the other about an inch below the bottom of the center fins. Construction Rating: 4 of 5

Finishing:

White primer was applied in three coats prior to the first sanding and I used 150 grit to cut away any excess epoxy resin left from the fiberglassing. A second round of primer was added, 2 additional coats, and I used 220 grit to start and finished with 400 grit. I had a problem with the primer adhering in spots and it began to wrinkle immediately after being applied. I had forgotten to clean the body tube so I used some Acetone on a rag and cleaned the area, which removed the primer too. Once I did this, the tube re-primed like a dream. After a total of about 7 coats of primer, with sanding in between every 3 coats, the model was ready for paint.

White Krylon Flat was used to paint the model as I was going for the scale look. After a couple days drying, I used Testors Gold for the two stripes and they painted well.

Now for the fun part! I wanted to build a close-to-scale rocket model of the HARM, but all Launch Pad kits do not come with decals. I had many photos of the REAL HARM, so I decided to make my own. After spending a week or so at the PC, they were complete. I printed them on water-slide paper I purchased from our local Hobbytown USA. Since they were printed with a laser printer, I didn't need to seal them, but I used MicroScale Decal Film to give them a sealed coat or two just to make sure. The decals were applied and the results were astounding. It actually makes the model look REAL! Anyone who wishes to receive my templates can simply send me an email and I will get them to you. Print them on a Color Laser printer and you are all set. The templates are in Word document form so almost any PC can read them. Note that the black lines at the tail and 1/64" chrome tubing lines were not decals and actually cut from Monokote adhesive sheets.

Now for the fun part! I wanted to build a close-to-scale rocket model of the HARM, but all Launch Pad kits do not come with decals. I had many photos of the REAL HARM, so I decided to make my own. After spending a week or so at the PC, they were complete. I printed them on water-slide paper I purchased from our local Hobbytown USA. Since they were printed with a laser printer, I didn't need to seal them, but I used MicroScale Decal Film to give them a sealed coat or two just to make sure. The decals were applied and the results were astounding. It actually makes the model look REAL! Anyone who wishes to receive my templates can simply send me an email and I will get them to you. Print them on a Color Laser printer and you are all set. The templates are in Word document form so almost any PC can read them. Note that the black lines at the tail and 1/64" chrome tubing lines were not decals and actually cut from Monokote adhesive sheets.

I did not use the small balsa strips they give you for the tail since the real HARM does not have this area elevated. The black strips worked better. Also, some of the decals are actually labels, so I printed these on label paper, topped them with clear packing tape to make them paint proof, then applied them to the appropriate locations.

Finally, the entire model was sealed using TopFlite Flat Clearcoat, which can be found at many R/C hobby shops. Light "dusting" layers were used so the decals weren't attacked by the clearcoat solvents and this worked well. Two to three coats are recommended and the beauty of it is this clearcoat is made fuel-proof for R/C aircraft, so it can be easily cleaned after several launches.

One of the last steps performed was the installation of the shock cord and parachute. The recommended method of attaching the shock cord is to use a supplied Estes type tri-folded paper glued to the side of the body tube. This is not satisfactory for a model of this size. I recommend you take 2 sets of 70 lb test Kevlar line and loop, tie and CyA them around the motor mount. Next, drill a small hole through the mount plate right up against the motor tube. The Kevlar line threads through the hole and extended six inches out the top of the body tube, where I tied it to the shock cord. This is a much stronger and safer way of mounting the cord and will help prevent those nasty "zippers" that can occur when too much stress is put on wall mounted shock cords during ejection.

One of the last steps performed was the installation of the shock cord and parachute. The recommended method of attaching the shock cord is to use a supplied Estes type tri-folded paper glued to the side of the body tube. This is not satisfactory for a model of this size. I recommend you take 2 sets of 70 lb test Kevlar line and loop, tie and CyA them around the motor mount. Next, drill a small hole through the mount plate right up against the motor tube. The Kevlar line threads through the hole and extended six inches out the top of the body tube, where I tied it to the shock cord. This is a much stronger and safer way of mounting the cord and will help prevent those nasty "zippers" that can occur when too much stress is put on wall mounted shock cords during ejection.

Finally, I used a Paratech 24" "square" nylon parachute for recovery instead of the supplied mylar chute. A piece 8" square Nomex was attached to the Kevlar cord for heat shielding so wadding was not required. Finish: 3 ½ of 5

Construction Rating: 4 out of 5

Flight:

The motor for it's first flight was an E18W-4 RMS reload, which is what I used to make this bird airborne. The rocket lifted off the pad with authority, yellow flame and white smoke trailing out the business end! Flight was straight and true; it took to the skies like it was on rails, even with the large center fins! This appears to be a good load for the model and I plan on using it for several more launches in the future.

Recovery:

The parachute deployed right at apogee. I was concerned about seeing the model since it is almost all white, but the brightly colored parachute made it easy to track. Landing was uneventful and the rocket was recovered intact. The Nomex did it's job as the parachute didn't have any signs of heat deformation.

Flight Rating: 5 out of 5

Summary:

The HARM AGM-88A is nothing less than astounding! The rocket just plain looks good, and it is a very close scale representation of the real missile. Construction is easier than it looks and the end result was worth any extra effort. A few things could be improved, such as the paper boat tail template size, parachute mount and specifications for CG. I would also like to see additional documentation showing more scale lettering information and placement on all their kits. These minor flaws aside, this is one fine model. Just keep in mind that this is definitely a builder's kit, which worked out well as I really enjoy the building process. I now have a fleet addition that is true to scale and a real "eye catcher"! If you like the Launch Pad kits, then you have to get one of these; it's a great buy for the buck! Close-up pictures of the decals can bee seen at this thread on The Rocketry Forum.

Overall Rating: 4 out of 5

Other Reviews

- The Launch Pad HARM AGM-88A By Joe Cacciatore (May 1, 2011)

Single stage scale model of HARM AGM88-A missile with 24 mm ("D" type) engine mount. Comes with 18"x30" mylar chute. Like most of the military scale models sold by TLP, this kit has 8 fins. The mid rocket fins are rather unusual in their size and shape. The fins are regular balsa wood and the body tubes are regular cardboard tubes like Estes. The engine mount is also similar to Estes being ...

|

|

Flights

|

|