Currell Graphics Airship R-100 Plan

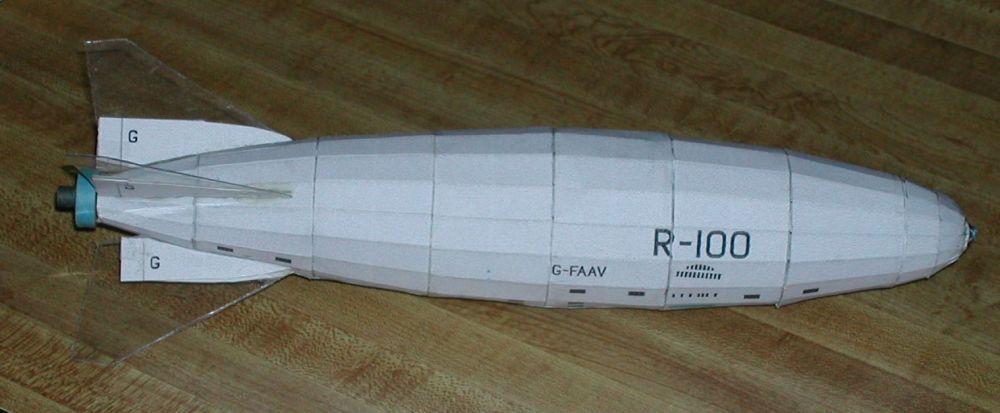

Currell Graphics - Airship R-100 {Kit}

Contributed by Dick Stafford

| Manufacturer: | Currell Graphics |

Brief:

Brief:

After seeing EMRR’s review of the Model Minutes Space Racer , my interest in flying paper models was renewed. We shared some links to free paper models, including the Currell Graphics site. Quite a while ago, I had seen that someone had made a flying version of the “Friede” moon rocket, and I thought maybe I’d build one. However, what really caught my eye was the Airship R-100 dirigible. This is an accurate and detailed 1/700-scale replica of the R-100, which was built by the British government circa 1930. I’ll warn you that this was not the most successful conversion. I jumped in without adequate planning, so the reader may not want to build it as I did. It did fly fine, however, on a MicroMaxx motor. This review will give a feel for the model and provide some pointers if you should decide to build one.

Construction:

- Four sheets of white card-stock

- Thin clear plastic for extended fins

- Apogee 13mm phenolic tube,

- 1 5/8-inch long 13mm-18mm centering ring

- Thin plastic 6mm tube from a pen (motor mount)

- 1/8-inch section of spent MMX motor

- Hand cut cardboard centering rings ~8mm-13mm.

- Piece of a BiC pen’s ink tube

The instructions for the Airship R-100 are provided in a .pdf file. They are three pages long and include very understandable schematic assembly drawings. The plans themselves are four pages long and all the parts are keyed to the assembly drawings. I chose the colored versions to print on white card-stock. A line drawing version is also available if you want to print the plans on colored or metalized paper.

The model is very detailed and many of the trim components are very tiny. There are 56 parts to cut out, including a display stand. (if you really are a masochist you can build Currell’s scale mooring tower). I built the model in my lap while watching the boob tube and decided to skip the details (engines, control car). They were just too small. My first tip if you want to build this model (for flight or static) is: work on a good surface in good lighting. Overall, I had a hard time assembling the body. I really needed to have a work bench surface. The precision of my cuts was not good enough to get a perfect fit in the components. In some places, I used scissors whereas an X-acto knife and cutting pad should have been used throughout.

The body is comprised of seven conical sections supported by bulkheads. Each bulkhead consists of two cutouts. I cut 13mm holes in each bulkhead assembly to accommodate a full-length tube. One point is not clear without reading the text of the instructions. Many of the components require that you score the paper with an X-acto knife to ensure precise bends. For example, the body wraps and bulkheads are all 16-sides structures, which must be scored in order for them to conform properly. The nose consists of an additional three conical sections and the tail is one cone. On the latter, I cut the end portion off to accommodate the tube.

The fins are normally made from two cutouts folded over on themselves, so the final fins are four layers thick. However, I knew I needed a lot more fin area for a stable model. Therefore, I built clear fins from some thin packaging plastic, and overlaid the decorated printed fins over these for show. I used the provided paper parts as a template to get the contour and through the wall tabs right. The entire model was built with white glue, except for the plastic fins, which are held on with Liquid Nails.

I had planned to use tumble recovery with a 13mm motor, probably an A10. However, I found that, even with the larger fins, some nose weight would be required. This would make the rocket too heavy (i.e. lawn dart recovery) so I punted and built a MMX adapter.

The adapter is a short piece of 13mm tube just long enough to pass through the first bulkhead. A 13mm-18mm centering ring acts as a thrust ring. I used a section of a thin walled plastic pen for the motor tube and glued in a piece of a spent motor as a block. I hand cut centering rings from two cardboard circles that popped out of an Estes centering ring set that came in a Designers Special. I used Liquid Nails to bond to the plastic, and carpenter’s glue elsewhere on the adapter.

No finishing is required as the hull of the model is pre-printed. I used a clear coat to protect the printing.

Flight:

I knew the MMX-II motor would be underpowered but gave it a shot anyway. I removed the ejection charge from the motor and wrapped some tape on the motor adapter so it was just a little snug. The Airship R-100 lobbed to a whopping 12 feet or so and fell to a soft landing. Another member of my fleet suitable for front yard launches.

Summary:

This is a nice kit if you like paper models, although it is actually a lot more difficult than your typical 3/4FNC rocket. The detailing is great. Here is what I would do to make it a better conversion:

- Cut all bulkheads for a 18mm tube and use A or B motors.

- Create a nose cone by splitting the kit near the front. This will require replicating a pair of bulkheads. I would mount a section of tube in the nose cone add a 18mm coupler to mate with the main tube.

- Add nose weight as required.

|

|