| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Qmodeling  |

Brief:

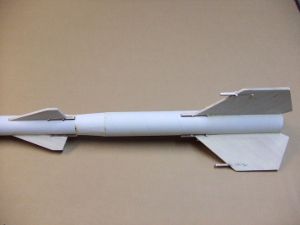

With the Raptor, QModeling has ventured away from the mode of upscaling Estes classics and introduced their own

design. This one is BT-60 based, tapering to BT-55 with some miltary-style guns/antennae included as well.

Construction:

I ordered this during their Christmas sale, scoring #25. The kit arrived in 3 days, not too bad during the

pre-holiday rush. Parts were generally exceptional quality. I would point out though a couple minor differences between

this and the typically superb Q-modeling quality--the nose cones is a basic blow-molded plastic nose cone like you'd

see on a typical BT-55 commercial kit rather than a nice cast resin cone, and the upper body tube was coarsely cut but

marked as the aft end, covered by a transition, and noted in the bag as a time-saver in production to meet the

Christmas rush. Neither of these detract from the quality of the kit, but I just wanted to point out that if you've

been spoiled by other QModeling kits, these are a very slight step back down the quality ladder.

Overall, you get a pretty extensive collection of parts:

Overall, you get a pretty extensive collection of parts:

- Plastic nose cone

- BT-55 upper tube

- BT-60 lower tube, slotted for TTW fins

- Foil-lined 24mm motor tube (heavy wall)

- 6 Laser cut 1/4" balsa fins

- Assorted cardboard centering rings, transition shroud

- Laser-cut balsa motor/fin brace assembly

- Top-Flite recovery system (Nomex® pad, 18" nylon chute, 9' 200# Kevlar®)

- Waterslide decals

QModeling generally does an exceptionally thorough job of documenting and illustrating the construction of their kits, and this one is typical though it had a couple minor spots where it looks like this was a first draft. Overall, construction took me about 3 hours plus prep/finishing time, and I'd rate it slightly above a 2 on the 5 point skill level scale. The transition and motor mount assembly are the only aspects even slightly challenging, so this should not be considered an intimidating project at all.

The motor mount assembly is classic QModeling--a complex looking series of braces and rings that surround

the motor tube. Everything goes together very smoothly in a matter of minutes, after which you'll alternately be amazed

by how great a job you did and by how potentially over-engineered this thing is, but that's part of the fun of a kit

like this... One really neat aspect of this particular design is that the motor hook is designed to be retractable so

that the rocket can stand on its fins for display. This is accomplished very simply by cutting a 1/2" long slot in

the motor tube. The motor is retained via a couple internal centering rings, plus the motor hook fits pretty snugly in

a groove between the centering ring and motor tube. For what it's worth, this was one part of the instructions that

comes across as slightly confusing--placing the centering rings and marking the tube would be more straightforward if

all the illustrations designated forward and aft ends of the tube. It's pretty obvious once you know how the sliding

hook works, but if you're not familiar with it, you might scratch your head a bit and have to reread a few times.

The motor mount assembly is classic QModeling--a complex looking series of braces and rings that surround

the motor tube. Everything goes together very smoothly in a matter of minutes, after which you'll alternately be amazed

by how great a job you did and by how potentially over-engineered this thing is, but that's part of the fun of a kit

like this... One really neat aspect of this particular design is that the motor hook is designed to be retractable so

that the rocket can stand on its fins for display. This is accomplished very simply by cutting a 1/2" long slot in

the motor tube. The motor is retained via a couple internal centering rings, plus the motor hook fits pretty snugly in

a groove between the centering ring and motor tube. For what it's worth, this was one part of the instructions that

comes across as slightly confusing--placing the centering rings and marking the tube would be more straightforward if

all the illustrations designated forward and aft ends of the tube. It's pretty obvious once you know how the sliding

hook works, but if you're not familiar with it, you might scratch your head a bit and have to reread a few times.

The motor mount assembly wraps up with a pair of centering rings, one on each end. The ring on the forward end is a hefty particle board ring with a hole for sliding the 200# Kevlar® through, serving as an anchor for the recovery system. The finished assembly goes into the main BT-60 body tube carefully lined up with the fin slots.

The body tube/transition assembly is not too tough. The upper BT-55 gets a set of cardboard centering rings to hold it in the BT-60. The rings were a bit tight but light sanding resolved it. Before gluing anything together though, be sure to mark a fin alignment line on the BT-60, then 3 fin lines on the BT-55 (using a wraparound guide). As noted, my BT-55 had a pretty rough cut on one end, marked with an X, clearly intended to be the covered aft end. I rolled the transition shroud from heavy cardstock. I wouldn't have minded a slightly less rugged stock, as mine wrinkled slightly when forming. Since it's not structurally critical, thinner/lighter might work just as well and be easier to form. The finished fit though was perfect.

Next up comes fin construction and placement. Construction is easy: the three main fins get a balsa

"antenna" in a pre-cut slot and a small bulkhead in a slot at the bottom. The forward/secondary fins get just

a bulkhead. The bulkhead and antenna look a lot alike, so be careful to not mix them. The bulkheads are just a little

bit wider.

Next up comes fin construction and placement. Construction is easy: the three main fins get a balsa

"antenna" in a pre-cut slot and a small bulkhead in a slot at the bottom. The forward/secondary fins get just

a bulkhead. The bulkhead and antenna look a lot alike, so be careful to not mix them. The bulkheads are just a little

bit wider.

Main fins are mounted through-the-wall into the slotted body tube and fit fine without any sanding or trimming. The upper fins mount flush to the BT-55 with the aft edges of the bulkheads flush with the edge of the transition.

Note that "bulkhead" might not be the best term for the balsa details under the fin edges, as it has very different meanings in rocketry, including solid interior disks and payload type bays. I point this out because in the next set of steps, you're instructed to cut the supplied launch lug in half and mount to each set of fins. The aft lug on the BT-60 goes "against the bulkhead", meaning mounted to the joint between the fin and the balsa detail that protrudes beyond its edge, not against the body tube. The forward lug goes against the fin, well away from the body tube to clear the lower BT-60, "not against bulkhead". A simple standoff might have been a better idea with the aft lug mounted flush against the BT-60 rather than against the fin.

To finish construction, there's a very clever step of adding a centering ring in the forward BT-55 tube, which helps to keep the chute in the forward part of the tube during flight. This is especially important to maintain the CG during thrust, preventing a chute from sliding back and causing the rocket to go unstable.

The kit even includes one other neat innovation acting as an anti-zipper device. This is especially

handy considering the shock cord is heavy Kevlar®.

The bumper is a simple rubber disk--drill a hole in it, slip the Kevlar®

through it, and tie it off near the point at which the cord exits the body tube. I found this to be a nice touch.

The kit even includes one other neat innovation acting as an anti-zipper device. This is especially

handy considering the shock cord is heavy Kevlar®.

The bumper is a simple rubber disk--drill a hole in it, slip the Kevlar®

through it, and tie it off near the point at which the cord exits the body tube. I found this to be a nice touch.

Finishing:

To prep for paint, there's a lot of balsa grain to fill and plenty of tube length for spiral filling if you're so

inclined. After the prep, just a basic Elmer's Fill 'n' Finish job, I went with three coats of light gray primer,

sanding the first one almost completely off to finish off the surface prep.

The color scheme for the final colors is gloss gray for the bottom, white for the top, and black for the transition. The good news is no fin masking, but the bad news is the transition masking around the bulkheads forward of the secondary fins is a pain, and when black seeps under onto white, you'll never scrape it off effectively.

Once the paint's fully cured, the waterslide decals add some nice detail. The decals are great quality and go on smoothly. The only little gotcha I ran into with them was that the lower body tube seems to have shrunk from initial design to final release--the U.S. Army decal barely fits in the 5" area from transition to fins, yet the placement guide offsets it by 8".

Construction Rating: 4 out of 5

Flight:

I decided to brave heavy winds gusting to 20 mph for the first flight and loaded up a D12-5. It took off fairly

quickly with a slight weathercock though generally impressed with the way it held up to the winds. Apogee was around

400 feet, affected in part by the weathercock.

The -5 delay was a bit too long though I suspect on a calm day a -3 might be a bit too early as well.

Recovery:

The Top Flight Nomex®

pad and chute were excellent, bringing the model back down safely. I expected at least a gun or two to have snagged and

broken off, but everything was fine. The model literally dodged a few bullets though drifting just over a dense tree

line and landing in the middle of a neighboring gun range with several people shooting that day. They generously

stopped shooting long enough to pull my rocket out of harm's way, and it was waiting for me when I arrived.

Flight Rating: 4 out of 5

Summary:

I liked this rocket and building any QModeling kit is a pleasure, but for me there just isn't anything

"special" about the design compared to some of their other products. Don't get me wrong, this is a fine kit,

but I'd generally recommend springing the extra $10 or so for a Snooper, Vega, Viper, or better yet, go for the grand

Andromeda.

Overall Rating: 4 out of 5

Other Reviews

- Qmodeling XP Raptor By Dave Brunsting (February 9, 2009)

Brief: The XP Raptor is a single staged 24mm sport flying semi-scale rocket. I won this rocket in EMRR's recent rocket video contest where I placed 5th. I thought it only fitting that I try to get it built and a review submitted as soon as possible especially since it is on the EMRR hit list. Construction: The parts list: Parachute Compartment C-Ring 3x Primary Fins ...

|

|

Flights

|

|

|

|

H.C.M. (February 12, 2009)