Descon Quasi-Scale PEPP Aeroshell

Scratch - Quasi-Scale PEPP Aeroshell {Scratch}

Contributed by Kevin Trojanowski

| Manufacturer: | Scratch |

Quasi-Scale PEPP

Aeroshell

by Kevin Trojanowski

So what's a quasi-scale PEPP, you ask? First, a bit of history. A number of months ago, a group of us were hanging out in the ROL chat, talking about various subjects, with rocketry even coming up once in a while. Peter Alway was kind enough to treat us to an image of an odd looking contraption he had recently made a drawing of. That particular contraption is discussed in his NARAM 43 R&D Report - Supplementary Material to Rockets of the World. If you review his report, you'll find a discussion of the PEPP Aeroshell, including a drawing with measurements. An even better reference is his 2001 Supplement to Rockets of the World, which contains additional information that's not included on the web page.

What does this have to do with DESCON, and what about this quasi-scale nonsense? While trying to come up with an idea for the DESCON, I made lots of sketches that look like lots of things other people have flown, plus a few oddball things that I may try to build and fly at a later date, but I wasn't happy with what I was coming up with. Then I remembered Peter's PEPP Aeroshell upload to ROL. Peter was kind enough to provide me a link to his R&D report, where I could get more information. From there, I started building. My first goal was to try to make it true to scale. Then, I realized I was running out of time and decent weather, so while the basic shell (the cone) and the motor ring are true 1:10 scale, the motors themselves are not, nor are the supports for the motor ring. Thus "quasi-scale".

Construction

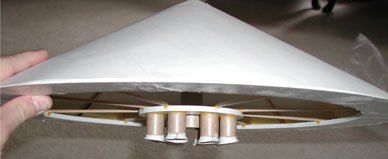

The original PEPP Aeroshell is 180" in diameter and 55" tall. While a full-scale version would've been really, really cool, I thought it a bit excessive. So, I took the lazy way out and went with 1:10, which means the base of the Aeroshell is 18" and the cone is 5.5" tall. The first step is to download a copy of VCP and print out the six-page template to create the cone. The template pieces were cut out and rubber cemented to posterboard, in their proper positions. Cut out the template and glue it together. I used a strip of standard copier paper to form the seam in the cone.

Next, I needed a ring of foam board to form the band around the bottom of the Aeroshell. The problem was how to cut an 18" diameter circle. After thinking on it for a bit, I hit on the idea of taping an X-Acto blade to the end of a dowel and using a small nail through the dowel as the pivot point. Since the circle needed is 18" in diameter, I drilled a hole at 9" and inserted a small nail. Poke the nail through the foam board and pivot the dowel, and a nice, easy circle is cut. This method works best if you cut through the board in three or more passes. Go any faster and the X-Acto blade tends to hang up. Once the outer circle was cut, I then cut an inner circle 14 3/8" in diameter. The inner circle was set aside, leaving an ring of the proper diameter to form the base of the Aeroshell.

I did a test-fit of the ring into the cone, and it fit quite nicely, except that it would not fit all the way up it. Not really surprising, when the shapes are compared -- the foam board forms a short cylinder, while the cone has an angle to it. Some trimming with an X-Acto knife and I had the foam board trimmed at an angle that would allow it to fit nicely into the cone. I used masking tape to hold the ring in place, then mixed and applied epoxy to hold it permanently.

Once the epoxy cured, I glued an 24mm coupler into the nose of the cone, being careful to make sure it was aligned perpendicular to the base of the cone. This allows for a good, solid attachment point for the motor mount. Being poster board the cone itself needed reinforcement, so I glued in strips of 1/8" x 3/16" balsa that run from the coupler to the base of the cone.

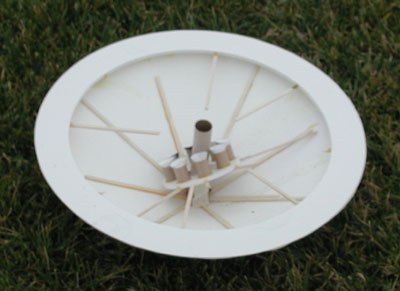

The next step is to cut out the motor ring. Notice in Peter's article that while there are two motor options, in both instances, it appears that the motor ring itself is the same diameter. Here, I didn't go for 100% scale in terms of the profile of the ring, but I was trying for a proper size. The circle jig was modified to cut an outer circle of 4 1/2" in diameter and an inner circle of 2". The ring formed between these two circles is an appropriate size for the motor ring.

Once the motor ring was cut, it was time to figure out the motors. This is where I began to work on a "close approximation" of the actual AeroShell. I cut 8 pieces of 18mm body tube, each 1" in length. I then used VCP to create transitions that were 10mm at the top, 24mm at the bottom and 1/2" in length. Awfully darned convenient that VCP lets you mix units of measure! These transitions were used to form the "nozzles" on each motor. The transitions were assembled and affixed to the motor tubes with CA, each at a slight cant. The motors were evenly spaced around the motor ring, and affixed with Titebond glue.

Once the motor ring had dried, I used more of the 1/8" x 3/16" balsa to make mounting braces for the ring. If you look at Peter's sketch, you can see their approximate placement. I made a reasonable attempt to match this, but didn't worry much on precision. At this point, I was considering my creation to be a prototype, and plan on doing a more accurate job sometime in the future.

The motor tube is a 5 1/4" piece of 24mm tubing with an engine block glued 2 1/8" from the aft end. I glued a launch lug at about the midpoint of the tube. Since I wasn't sure, vertically, where the motor should be placed, I slipped the forward end of the motor tube over the coupler and slid it as far forward as it would go. I then used strips of masking tape to hold it to the cone.

To allow the launch rod an exit point, I slipped a launch rod through the launch lug from the near and used it to carefully poke a hole in the cone itself. I then used the point of a pencil to slightly enlarge the hole, to keep the launch rod from dragging on the cone.

The Moment of Truth - Launch Day!

On November 25th, my friend Kevin Rich and I headed out to our low power field for some testing. I created some very rough simulations of the PEPP in RockSim, which indicated that the Estes E9 was likely the best motor for this creation of pure drag. Bob Kaplow's comments on his experiences with Happy Meals indicated that low thrust, long burn motors work best for such rockets. I considered an Apogee D3, as the epitome of this motor type, but the thrust is far too low to move the PEPP. So a pack of E9-4s was acquired. E9-0 would've been preferred, but they are not available.

I used a pencil to poke about 1 square of recovery wadding into the front of the motor tube, past the motor block. This served to keep the ejection charge from blowing holes in the top of the cone when the motor kicks out. The motor was inserted, an igniter added, and she was put on the pad. 5... 4... 3... 2... 1... Doesn't exactly scream of the pad; more of claws its way off, but up it went, fairly stable, too!

(Launch photo will be added, once I get it scanned; static photos were done w/ digital)

As hoped, at apogee, the Aeroshell flips over, just like the Estes Snitch. It flopped down, with the motor still smoking, and just before meeting the ground ("impacting" and "hitting" describe too forceful of a landing; it comes down amazingly gently), the motor popped out, easily visible to us.

Up until ejection, everything was intact. The concussion of the motor ejection, however, cause the supports for the motor ring to snap, leaving it sitting in the inverted cone. While the motor selection and placement worked well, the motor ring attachment was insufficient. When I rebuild, I plan on using 1/8" or 3/16" dowels, to provide more strength.

We launched the Aeroshell, sans motor ring, a second time with an E9-4, and it worked quite nicely.

Since we had plenty of time to play, we decided to see how the Aeroshell would perform with an Aerotech F12. The motor was built without an ejection charge, as I had no desire to lose my RMS casing. Wadding was inserted into the delay well and a small piece of tape used to hold it in place. The boost, this time, was very squirrely; I suspect the weight of the motor was a bit much, relative to the thrust. The problem may also have been caused by the motor sitting too far to the rear of the cone, since the forward closure of the RMS casing would not fit down inside the engine block I used. The casing was held in place with a strip of masking tape, as a precaution against losing it.

As a final test, I wanted to see if it worked better with the motor closer to the front of the cone. So, I whipped out the rocketeer's miracle tool (known as a "Leatherman" to people who waste tools on hunting and fishing) and cut approximately 1" from the front of the motor tube. A little masking tape and the tube was back in place again. Since the E9 had worked so well, I installed my last one. This flight was rather squirrely and reached nowhere near the stunning 75' - 100' feet that the first two flights reached. Obviously, the longer motor tube works better.

Conclusion

The Quasi-Scale PEPP Aeroshell proved itself a success, and an entertaining rocket to fly! An E9-P is what I will likely use next time, as the ejection charge really serves no purpose. I may also experiment with some additional RMS motors, if I can find anything that comes close to the E9 in simulations.

I also plan on building something a bit closer to scale, in terms of the motor ring and its attachment. The first one flew amazingly well and behaved itself quite nicely.

Credits

Thanks to Peter Alway for posting that original picture which gave me the idea for this project in the first place. Peter also deserves a tremendous amount of credit for his totally awesome Rockets of the World and all of its follow-ons. If you haven't bought them yet, you need to! I know I still need to complete my collection.

Thanks also goes to Kevin Rich for helping me out when I feel the urge to fly some oddball DESCON entry. He's also the bane of my wife's sanity by encouraging me to fly more, more, more motors!

Finally, a finger should probably be pointed at Mark Simpson for teaching me that when it comes to rockets, different is definitely better!

Sponsored Ads

|

|