Scratch Love Boat AKA. Lifeboat Original Design / Scratch Built

Scratch - Love Boat AKA. Lifeboat {Scratch}

Contributed by Ray King

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Scratch |

Brief:

This is my second entry for the EMRR “Spaceship Design Contest – 2009”. The name I had previously used and planned to submit was the “The Lifeboat” because of the intended use of the X-38, but during the launches today my cousin’s kids started calling it “The Love Boat”. So I decide to change the name to: THE LOVE BOAT.

Plans:

I based this design on last year’s design of the FWS rocket where the engine tube sub-assembly ejects out

the rear of the rocket. In this case used an 18mm engine rather than a cluster.

Construction:

Component Description:

- 030” Thick Polystyrene Sheet

- 1 - 1/4” Balsa Sheets

- 1 - 1/8” Balsa Sheets

- 1 – 3/16” Balsa Sheet

- 1 – BT20 - Main Engine Tube – 10.0” long

- 2 – BT20 – Main Support Tube – 6.0” long

- 2 - Yellow Tube – 1.0” long

- 1 - 1/8” Launch lugs

- 36” - 175 # Kevlar® String

- 24” - .375” elastic shock cord

- Nose weight

- 24” plastic parachute

- Fiberglass material & Epoxy

- Mylar Tape

Main Body Tube Assembly

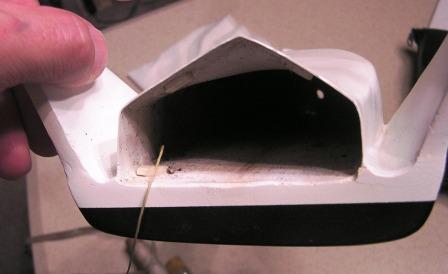

I started by cutting the BT20 tubes to length (2 @ 6.0” and 1 @ 10.0”). I then cut out the bulkhead from 1/8” balsa sheet (see template). I glued the 3 tubes together side by side (see picture). I then slide the bulkhead in place and epoxied it to the tube sub-assembly. Next, I glued a launch lug in the center of the tube assembly. Finally, I attached the elastic shock cord to the main tube using 5 min epoxy to secure it in place.

Vacuum Formed Shells

There are 3 separate vacuum formed pieces in this rocket. The top half, bottom half, and cockpit. The top and bottom halves were vacuum formed use to shaped foam masters. The cock pit is form over a balsa master (see pictures). Also see the Tip on vacuum forming.

Body Assembly

I glued two .125” sheets of balsa on edge to form a 6” wide piece of balsa. I glued the top shell to the 6” piece of balsa. Next I trimmed the balsa to within 3/8” of the shell for the front half and left the back half over hang. I then glued the lower shell to the balsa sheet making sure the 2 halves align as perfectly as possible.

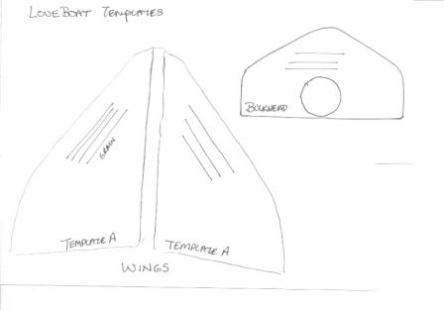

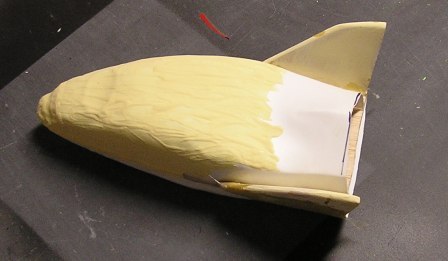

Next, I cut out the 2 side wings (see template A) from the ¼” balsa. I rounded the top and front edges of each wing. Then I sand the angle in each wing to get the appropriate look. I epoxied wings in place and trimmed the excess of the .125” balsa up to the wings.

I used 5 minute epoxy around the outside of the shell and balsa to ensure a good strong joint.

I wasn’t happy with the interface between the body and balsa wood wings so I decided to apply fiberglass cloth to this joint to improve the appearance as well as add strength.

Finally, I trimmed the cock pit section to fit the top of the shell and glued it in place.

Final Body & Tube Fitting

The launch lug hole needed to be cut into the shell – I slid the main tube sub-assembly into the shell assembly and using a lug rod to mark the location of where the hole needed to be cut. I carefully used my Excato knife to cut the hole in the shell.

I marked the location of the tube subassembly so I could add bulkhead supports. I cut 4 - .125” x .25” pieces of balsa and glued them in place to resist the engine thrust on the bulkhead.

Nose Weight

I used 2 old engine tubes and filled each with 1 oz. of weight each and secured it in place with Mylar tape at the very end of the end of the 6” tube.

Finishing Main Body Assembly

I sprayed 2 or 3 coats on the entire shell assembly with Rust-oleum White Plastic Primer #209460. After lightly sanding the primer, I sprayed white gloss (Testors Gloss White #4696 ). Next, I masked the bottom area for the black and sprayed gloss black (Testors Acryl #4695). After the black, I added NASA decals. Finally, I added 2-3 coats of Krylon Crystal Clear Gloss.

Decals

I printed the decals on Experts-Choice clear water slide decal material. I cut them out and applied them as the pictures shows.

Flight:

Flight Prep & Flight Results

I made the first of the 3 flights in March – this rocket was not painted. Today, I planned to do at least 2 more flights today after paint. I did a spin test and found that after paint I needed to add a little more nose weight.

I added dog barf, folded the parachute, and loaded the engine sub-assembly. Once in place I added a C6-3 engine. I

slid the “Love Boat” on the launch rod. 5-4-3-2-1----- blast off. The boost was good, but not as high as I

thought it would have been. The parachute ejected and opened with a good recovery. The second flight (C6-3) was a

little better with more altitude. By the time, I recovered the rocket it was just about dark so I decided to not the 3

flight today, but did get 3 good flights with this rocket.

Summary:

Pro’s – NASA needs a better paint scheme.

Con’s – None

Other:

Thanks EMRR - this was a great project. I enjoyed the design and construction challenges. I am looking forward to

2010’s spaceship challenge.

|

|