| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstar_borderstar_border |

| Published: | 2010-08-02 |

| Manufacturer: | Edmonds Aerospace |

Brief:

Out of the bag and into the air in minutes. You do have to wait for the glue to dry. Like all

Edmonds' kits, an excellent design, laser cut premium balsa and clear instructions make Elcie a great introduction to

boost gliders.

Construction:

Parts consist of:

- Laser cut sheet of balsa - usual high quality.

- BT 5.

- Balsa nose cone - really bad quality.

- Crepe streamer.

- Kevlar® (R)cord.

- Tape.

- Launch lug.

- Screw eye.

- Instructions.

- Marking guide for tube.

First

thing was to try and sort out the nose cone. The balsa was soft and flakey. It was too large for the body tube and had

a very large shoulder on it.

First

thing was to try and sort out the nose cone. The balsa was soft and flakey. It was too large for the body tube and had

a very large shoulder on it.

After sanding it down to fit the body tube and then sanding the outside until it was flush with the outside of the bodytube, the nose cone was given three coats of thick sanding sealer. The Balsa is very soft and I had concerns over the screw eye holding into such soft material; in hidesight I should have just got a better nose cone from my parts box.

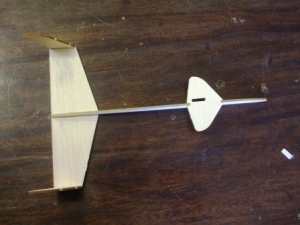

The glider is just five parts. In usual Edmonds quality, the laser cutting is perfect. The parts fit easily together. I tacked everying together with CA gel and then added wood glue fillets.

The

slot in the forward canard has square edges, I removed the edges that are forward bottom and rear top, so that the tab

on the booster slips easily on and off.

The

slot in the forward canard has square edges, I removed the edges that are forward bottom and rear top, so that the tab

on the booster slips easily on and off.

With a few of Edmonds gliders flown before, I have learnt to do nothing else to the glider, no sanding of leading or trailing edges, or lifting surfaces made, not even a coat of sealer, usually because they fly well straight off the table, and if it isn't broken - don't fix it.

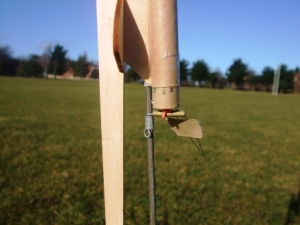

The pod build is easy. The tab that holds the glider is glued to the body tube. A marging guide is provided to help get it on straight. The shock cord is then glued into the seam between the tab and the body tube.

The

cord then extends up the length of the body and is held at the top by a strip of tape.

The

cord then extends up the length of the body and is held at the top by a strip of tape.

The launch lug is then glued over the seam where the cord went.

An eye screw is screwed into the base of the nosecone and then the shock cord is attached.

A crepe streamer is attached to the cord with a piece of tape that is supplied.

What isn't supplied is an engine block or any type of motor retainer. Both jobs are done by a bit of tape.

Construction Rating: 4 out of 5

Flight:

I used Odd'l rockets raise to hold the pop pod up on the rail - I would heavily recommend this

piece of kit at anyone.

First flight was on a 1/2A3-2T, good boost, clean separation of the glider.

The glider sort of fell flat for several seconds, and then shot off in a glide, gave a wide circling flight path,

a good glide.

The Kevlar® cord however cut through the tape holding it at the top. Pod recovered fine.

Second flight was on a full A. high boost.

Glider and pod failed to separate, as the nose cone and eye screw separated, despite being screwed and glued.

Nosecone and glider/pod both recovered without damage.

Flight Rating: 4 out of 5

Overall Rating: 3 out of 5

|

|

Flights

|

|