Scratch Six Appeal Original Design / Scratch Built

Scratch - Six Appeal {Scratch}

Contributed by Dave Rose

| Manufacturer: | Scratch |

(Contributed - by Dave Rose - 10/20/01)

(Contributed - by Dave Rose - 10/20/01)While attending our first LDRS this year, my son Chris, my wife Kathy, and I, witnessed the most impressive display of large rockets we had ever seen. The launch site in Orangeburg, South Carolina was unlike anything we have access to in Pennsylvania. The wide open, flat, grassy launch site was almost too good to be true. Couple that with a 10,000 foot above ground level FAA waiver, and you have a high power rocketeer's dream. Throughout the four day event, we watched rockets of every conceivable size and weight, powered by a variety of motors from "A" through "M", take to the clear, blue, South Carolina skies. When the announcement was made at Sunday night's banquet about the location of LDRS 20, Chris and I almost immediately started making plans to attend.

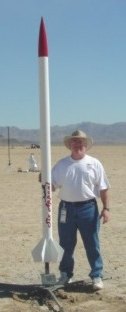

In addition to planning the trip to Lucerne Dry Lake, California, I started planning a rocket project to take along. Since I achieved my Level 2 certification this past August 5th, a powerful, 54mm motor based, dual-deployment rocket was a must. I decided to modify a plan I had been working on for some time, which resulted in a 4 inch diameter, 8 1/2 foot long rocket. The six-fin design which originally was called the "Six-shooter", had now become "Six Appeal".

The rocket was built using 4" PML

Quantum tubing and a PML nosecone. The fins were cut from .093" G10

fiberglass and will go through the airframe and mount to a PML extended

Quik-Switch 54mm motor tube. I cut the fin slots myself by marking the tube,

drilling a 1/8" hole at each end of the slot, and using a steel straight

edge and an X-acto knife. The Quantum tubing was only slightly more difficult

to cut than normal phenolic tubing.

The rocket was built using 4" PML

Quantum tubing and a PML nosecone. The fins were cut from .093" G10

fiberglass and will go through the airframe and mount to a PML extended

Quik-Switch 54mm motor tube. I cut the fin slots myself by marking the tube,

drilling a 1/8" hole at each end of the slot, and using a steel straight

edge and an X-acto knife. The Quantum tubing was only slightly more difficult

to cut than normal phenolic tubing.

A 10" section of coupler tubing and

3/16" plywood was used to build the avionics bay that will house a Missile

Works RRC2 altimeter. The altimeter, by the way, was won in a raffle at the

LDRS 19 banquet. The ejection charge holders were made using PVC pipe plugs

epoxied to each end that will hold Robby's Rockets ejection canisters.

A 10" section of coupler tubing and

3/16" plywood was used to build the avionics bay that will house a Missile

Works RRC2 altimeter. The altimeter, by the way, was won in a raffle at the

LDRS 19 banquet. The ejection charge holders were made using PVC pipe plugs

epoxied to each end that will hold Robby's Rockets ejection canisters.

The recovery system is a 20" Sky Angle parachute for the drogue and a 52" Sky Angle parachute for the main. Twenty-one feet of tubular nylon for shock cords at each end of the avionics bay, along with Nomex heat shields and shock cord protectors.

After priming and painting with gloss paint, I applied custom made vinyl graphics. The finished rocket weighs in a just under 10 lbs empty. The picture (above and right) was taken at LDRS XX just prior to a successful first flight, to 5,958 feet on an Aerotech K550.

|

|