| Manufacturer: | Rocket Pad |

![[Picture]](/images/archive/images/ratings/rating_rp_shark.gif) (08/01/04) There started to be some chatter about a "new" rocket kit manufacturer called Rocket Pad,

but the online community only saw kits listed on eBay. The auctions would be

one kit and then you might see another kit later on. One thing that caught my

attention was the variety of kits. There are those controversial

"clone" kits of old Estes and Centuri models, which I personally

avoid. Then there are unique kits such as the USSC Shark, which caught my

attention. I actually lost the bid (couldn't stay up that late), but e-mailed

the seller and he told me he had another, so I matched the price.

(08/01/04) There started to be some chatter about a "new" rocket kit manufacturer called Rocket Pad,

but the online community only saw kits listed on eBay. The auctions would be

one kit and then you might see another kit later on. One thing that caught my

attention was the variety of kits. There are those controversial

"clone" kits of old Estes and Centuri models, which I personally

avoid. Then there are unique kits such as the USSC Shark, which caught my

attention. I actually lost the bid (couldn't stay up that late), but e-mailed

the seller and he told me he had another, so I matched the price.

My USSC Shark came packaged very well and was shipped USPS Priority mail. Being my first exposure to a Rocket Pad kit, I readily jumped into the building experience. In general, I have been pleased, but follow along with this review.

The rocket includes a 14" long, 2.6" diameter, white paper body tube for the main body and a plastic nose cone to make up the 22 3/4" length. The kits includes three (3) sheets of 3/32" basswood for the fins, two (2) 1/4"x1/16" balsa strips for detail, two (2) 3" dowels, and cardstock fin cutting templates to make up the fins. There are two (2) plywood centering rings, a 24mm motor tube, thrust ring, and a retainer hook to make up the motor mount. The recovery system made up of a Kevlar® shock tether, elastic shock cord and an ASP 18" mylar parachute. To finish things up there is a 3/16" Launch Lug, a bag of clay for nose weight, and some water slide decals. The parts list said there was a "Green Spacer for "D" motor use", but my kit did not have one in there.

CONSTRUCTION:

The instructions are printed on 5 pages of 8½ x 11" paper. They include a single page with just the parts list, a specs sheet and then 3 pages of written instructions. There are no pictures or illustrations in the instructions, however, attached to the back of them are 3 pages of B&W photos of the motor mount, the rear end detailing where the motor hook should be aligned to, and the upper fin detailing where the balsa strip should be. There is also a 4th page with an illustration showing how to put the clay into the nose cone. In addition, there is a generic tube marking guide (for 1.637" and 2.6" tubes for 3 and 4 fins), and three (3) fin templates on cardstock paper.

The instructions were adequate for building the rocket, however there are quite of number of grammatical/spelling errors. There was also a few mistakes, such as on step #7 it says, "Mark the body tube (2.6" diameter) useing the enclosed marking guide. Use the marks with black dots only!". So this is a good idea since a general tube marking template is provided, however, there were no black dots on the Tube Marking Guide.

The rocket build was fairly typical, starting with the motor mount first. The retainer hook assembly is typical, but uses masking tape to secure its position in the center of the tube. The thrust ring is glued in behind/on top of the motor hook. The fit of the plywood centering rings was perfect and didn't require any sanding. The Kevlar® shock tether is threaded through the top centering ring (two small holes) and tied in a double knot. Once this is done, the motor mount is glued into the rocket body.

The Parts List provides a note on which basswood sheet to use for fin template #1 and #2. So after cutting out the templates from the cardstock, they are placed on the basswood sheets. There was a problem fin template #2. There was not enough basswood to make two fins by ~1/4". I simply made each fin 1/8" shorter so I could finish it up. There were no size problem for fin #1 and the top tail.

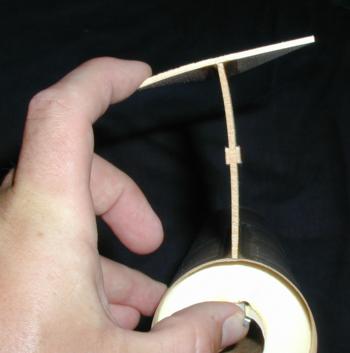

The potential problem for the upper fin is the direction of the basswood grain. First off, it is a good thing that it is basswood because these fins would not survive if they were balsa. However, the grain on the upper fin is parallel to the body tube verses the best known method of having it parallel to the leading edge. Notice the flex in the upper fin? Will it snap? Time will tell.

Once the fins are cut, sanded (rounded or airfoiled) as you deem necessary, they can be attached to the body tube. I used wood glue to do this and then used 5-minute epoxy for the fillets. I also fillets on the underside of the top tail.

The instructions are to add the Launch Lug 1 1/2" up from the bottom between the upper tail fin and a side fin. I didn't like this for two reasons: 1) typically and where possible the Launch Lug should be attached the CG of the rocket, and 2) I felt it should be on the bottom, between the two side fins for looks. I took action based on these two reasons and placed it 7 3/4" from the bottom.

The clay is squeezed off into smaller chunks, fed through the hole in the plastic nose cone and then tamped down with a dowel to make it stay.

I used my typical techniques for preparing the body tube and nose cone for painting. The basswood fins only took a couple coats of Plasti-Kote primer as well. After it was ready, I primed the primer with Krylon White Primer. I did this because I decided to use up the Krylon Yellow and Blue paint that I had to buy to fix the Tour De Deuce rocket. (You should use white primer under lighter colors like Yellow). I am personally not a huge fan of Krylon paint, but it turned out looking okay. I even painted the tip of the dowels with bright orange (instructions suggested red).

There are water-slide decals provided with the USSC Shark. I found these to require a longer soak period (closer to 60 seconds) to be able to slide. I also found these to be much less fragile (thicker) and actually a pleasure to work with. Bravo! I would have liked to see some blacken window decals included, but ended up cutting my own from some vinyl. Lastly I clear coated the rocket.

Overall, for CONSTRUCTION I would rate this kit 2 ½ points. It is a fairly straightforward kit to build, but the instructions need some work. The parts fit nicely and I'm pleased with the quality of parts such as plywood centering rings, basswood fins, and plastic nose cone (glad to not have to finish another balsa nose cone). The fact that the kit provided motor retention, is Estes "E" capable and has decals (nice ones too!) are huge bonuses. Missing one part, and not enough stock to cut out the fins, and that upper fin grain being parallel to the body tube forces me to rate this slightly below average. If you're experienced, consider these items and then go get the kit... if you can find one!

FLIGHT/RECOVERY:

Rocket Pad recommends the D12-3, D12-5, E9-4, and E9-6 motors.

My rocket weighed in at 8.4 ounces.

I was pleased with my finish and looked forward to flying this rocket since it is right in my favorite weight zone for 24mm rockets. D's are great for low altitude (my small fields) and E's and F's give the bird some altitude. This rocket weighs just about the same as my favorite Nordic Meanie.

My first

flight was on a D12-3. I had added a piece of Nomex shielding so that I didn't

need wadding. Everything was ready... 5, 4, 3, 2, 1... Lift-off! Yes, nice and slow, then picked up speed, then turned ever so gently, then reach apogee, then

ejection and full expansion of the silver parachute. Descent was a good

speed.

My first

flight was on a D12-3. I had added a piece of Nomex shielding so that I didn't

need wadding. Everything was ready... 5, 4, 3, 2, 1... Lift-off! Yes, nice and slow, then picked up speed, then turned ever so gently, then reach apogee, then

ejection and full expansion of the silver parachute. Descent was a good

speed.

Well, as I had anticipated, the upper fin cracked! Had I not been planning a "kit" review, I would have laminated this or got some larger basswood and cut it so the grain was parallel to the root edge. However, with kits, I like to try to build them exactly according to instructions.

There is a fellow on TRF that has said he has flown his many times and never had an issue. Great for him and that is why we say the reviews are only for information and that different rocketeers have different experiences. My seems to be what one could expect.

I was able to repair the upper fin and decided that I would strengthen it with some balsa pieces. After sanding and painting it looked pretty good. (colors are the same, one taken inside, other outside)

I was able to get out for a second flight (pictured above) on a D12-3 again. The flight looked great, like the first, and I really enjoyed it. After, ejection the rocket started to descend back toward me and so I snapped off a couple of pictures. I did this because it looked just like the first flight and fell with the tail cone angled for impact. And sure enough, it cracked the upper tail.

Since I cracked another tail fin I started

thinking about this and here are my observations. First, I noticed that as the

rocket descended (on both flights) the parachute leads the rocket body. The

rocket body hangs with the tail fin facing the direction that it is descending

and therefore it would hit the ground first. Upon inspection of my build, I see

where the Kevlar®

shock tether is attached to the upper centering ring is positioned down

(opposite side as the tail fin) and therefore it has a tendency to lean this

way.  I did a static

test at home and feel this is a strong argument, however, the lower fins may be

causing the drag that forces the rocket in this direction as well. I will test out my hypothesis by attaching it to the opposition side and flying it again,

but I'm convinced this is why my tail fin leads the rocket on descent.

I did a static

test at home and feel this is a strong argument, however, the lower fins may be

causing the drag that forces the rocket in this direction as well. I will test out my hypothesis by attaching it to the opposition side and flying it again,

but I'm convinced this is why my tail fin leads the rocket on descent.

I'll update this later once I can test it. If you have one of these kits and are not breaking the tail fin, can you please tell me where your shock tether is attached? (I have learned that the fellow on TRF is attached up, the same side as the upper fin and his does not break)

For FLIGHT/RECOVERY, I would rate this rocket 4 points. How could I rate this kit a 4 for flight when I have had two flights and both ending in damage? Because I dinged the kit's Construction rating for what is actually causing the breakage. Flight-wise, I love this rocket. Slow lift-offs and has the ability to fly on D12's and E9's. The parachute is sized right. I have some concern about the Kevlar® shock tether over time, but need some flights to test that out.

I give the rocket an OVERALL rating of 3 ½ points. The kit has great looks and is just the right size and weight for Estes D and E motors with smaller fields. I would recommend this kit to experienced builders and suggest they take precautions against the items I've highlighted. Wish we could get Rocket Pad kits from a website dealership, rather than having to pay for eBay and Paypal charges (which are no doubt built into the pricing) as well as them being in limited supply. Individual shipping and handling charges are high on these rockets as well, so maybe with more time, Rocket Pad will get a website together to offer these kits at a lower cost.

|

|