Scratch Baron Von Gofast Original Design / Scratch Built

Scratch - Baron Von Gofast {Scratch}

Contributed by Mitch Marchi

| Manufacturer: | Scratch |

Brief:

For my entry to the Essence Model Rocketry "Design This Spaceship" contest, I chose the Cool Rockets

"Racer" model. I thought this was a great design, and it really appealed to me.

I started by printing out the picture, and I also got 2 other views of the rocket off of the Cool Rockets web site. I then scaled these pictures to form some basic dimensions. Obviously this is a short, fat rocket with the body tube being a continuous curve. This really was going to be a challenge!

I took a little artistic license with my model versus the example, and I would like to explain why right off the bat. First, my model has 4 fins versus the Racer's 3 fins. I chose to do this for two reasons: one being that I have absolutely no experience with a 3 fin rocket that has its fins in an "airplane" configuration, and the other being that this model has very little fin area. This needed to be a flyable rocket, so in an effort to move the Center of Pressure as far aft as possible, I went with the 4 fin configuration.

The other major deviation is the pilot character. This was a personal decision: I really didn't like the example and thought the proportions to be way off. Add to this that a Racer needs someone to race against and Baron Von Gofast was born!

Construction:

To begin construction, I searched for a long ogive nose cone and a long boat tail section. I found what I needed in

the Estes Canadian Arrow kit. With a 2.6" diameter body tube, my model would scale out to be 18½" tip

to tail.

I started with the tail section. I cut down the coupler area of the boat tail to ½". This rocket was going to be much shorter than the stock Canadian Arrow, so I planned to shorten the motor mount tube and have my forward centering ring mount flush with the front edge of the boat tail. On the aft end, I left ½" of the excess stock, forming a nozzle. I then cut and cleaned only the rearward 4 through-the-wall fin slots. The fins would not have a long enough root edge to incorporate both through-the-wall provisions.

Then the motor mount tube was cut down approximately 1" to make it ¼" longer than the boat tail. After installing an E engine hook and motor block, I glued on the aft centering ring ½" from the business end of the motor tube. This centering ring then had the outside diameter sanded down until it fit snugly inside the boat tail and the motor mount tube was flush with the end of the nozzle. I glued this assembly into the boat tail using the forward centering ring to keep things aligned, but at this point the forward centering ring was not glued in place. After things dried, I removed the forward centering ring and applied a glue fillet to the aft centering ring.

To facilitate my shock cord, which is Kevlar string tied around the motor mount tube, I drilled a 1/8" hole through the forward centering ring. Passing the string through the hole, the ring was finally glued into place.

Using my scale dimensions, I determined that the body tube would need to be only 3" long! This rocket was almost all nose and tail cone! I cut the stock tube down and glued it in place.

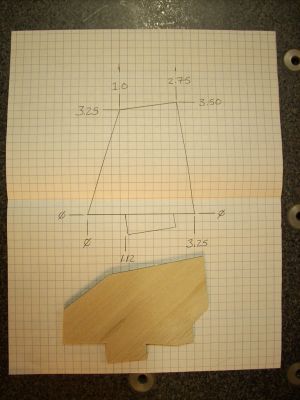

Next were the fins. I went with a double-swept design derived from my scale dimensions. I cut my fins out of 1/8" balsa, not only for the added strength, but the 1/8" fits the through-the-wall slots much better than 3/32".

I then sanded smooth radii into the leading and trailing edges of the fins to replicate the model more closely. This also greatly enhanced the look of the model. A large amount of fin surface area was lost due to this though.

Once all the fins were test fit and sanded smooth, I epoxied them into the boat tail. I added fillets which encompassed the forward through-the-wall "bump." At this point, all 4 fins were the same. To give it more of the "airplane" look, I cut the top 1" off of two opposite fins. I then fabricated the fin pods. The top and bottom pods were made from ½" diameter birch dowel rod with simple rounded ends. The 2 side pods were made from 5/8" dowel with the forward end being rounded and the aft end being tapered. I machined a 1/8" slot into these pods and glued them to the ends of the fins. The booster section was finally starting to look like something!

But I still needed a pilot! I had a few figurines that were intended for R/C airplanes that I had mocked up, but none of them looked that good. Finally, while scouring my local hobby shop, I found Baron Von Gofast! Originally intended to be affixed to a pine wood derby car, he was complete with a cockpit and canopy!

The size and scale were perfect! I epoxied him to the airframe and started on the filling and finish work. I filled the large gap around the cockpit and the grooves on the pods with Micro-Fill balsa wood filler. I followed this up with Evercoat polyester body filler (an automotive refinishing product).

It took several coats and lots of patience, but the contours were turning out really nice. I also used the body filler to smooth the forward through-the-wall bumps directly into the fin fillets.

In the meantime, I started on the nose cone. For starters, I cut the tip of the nose off and epoxied on a golf tee which had been sanded to blend the contours. Before gluing this on, I drove a small screw into the golf tee on the ball end. This screw would help to hold the tee on, as it would be engulfed in the epoxy which would later be added to the nose to hold in the ballast lead. I also cut off the aft end of the nose, not only to make it easier to add ballast but to add a little room to the payload bay. I would later add a fiberglass bulkhead plate inside to affix the shock cord to.

With the nose cone roughed out, I could assemble the rocket and determine the Center of Gravity. I did this using the "balance on the edge of a ruler" method. Not very scientific, but it works! Having done some math and roughly approximating the Center of Pressure to be 2" from the aft end of the rocket, I kept taping weight to the nose until the CG was 6 ½" from the aft end (1.75x body diameters in front of the CP).

Once I determined how much weight I needed to add, I was really glad that I had modified the motor tube for an "E" engine! It took a whopping 3½ ounces to balance out properly! I used #8 lead shot and epoxied it into the tip of the nose cone. In hindsight I could have added a little less, but an overstable rocket it better than an unstable one! The rocket ended up weighing 12.4 ounces ready-to-fly with an "E" engine in it.

Finishing:

In keeping with the "Baron Von Gofast" motif, I elected to go with "Red Baron" colors on this

machine. But since this was a spaceship, I "futurized" the typical red, white and black! My base colors were

pearl silver, pearl cranberry, and pearl black. All were Glasurit 54 series basecoats. I hand painted the cockpit with

Testors enamels and followed up with 3 coats of PPG DAU 82 clear coat for the entire rocket. The finishing touch was to

glue on the cockpit canopy!

Well, it was done. Almost. I've got to see if it will fly! I attached a 16" nylon parachute to the Kevlar shock cord and headed to the launch field!

Flight and Recovery:

Conditions were less than ideal, but about the best that I could ask for on a December day in Michigan! Overcast,

cold (15 degrees F) and only slightly windy (5-10mph). For the maiden voyage I went big and stuffed an E9-6 into it and

readied it for launch.

3...2...1...WHOOSH! You gotta love the sound of an E under heavy load! This is a great rocket to watch! A slow lift-off, followed by a little half roll. The fin pods make it easy to see the roll and follow the rocket. It weathercocked hard and seemed to travel into the wind as much laterally as it did high in a large parabolic arc. After peaking around 800 feet, the nose was pointed down when the chute popped, and it touched down about 300 feet from the pad.

The second flight was pretty much identical to the first although I had readjusted the launch rod and the rocket landed about 200 feet from the pad. For the third flight, I wanted to see what it would do on a "D" engine. Propelled by a D12-5, the flight path was the same as the E9 with the weathercock and arc, but altitude was only about 500 feet, which I expected. What I didn't expect was how late the ejection charge was. It blew at around 200 feet, nose pointed straight down.

It came down fast and hard. Unfortunately its path didn't carry it past the building like

the previous flights, and it made contact with the building about a foot off the ground. Ouch! It broke one fin off,

which can be seen laying right next to the booster, and the golf tee tip on the nose cone was broken from whacking the

frozen ground. Oh well, I was still happy with the results. It flew and was fun to watch!

It came down fast and hard. Unfortunately its path didn't carry it past the building like

the previous flights, and it made contact with the building about a foot off the ground. Ouch! It broke one fin off,

which can be seen laying right next to the booster, and the golf tee tip on the nose cone was broken from whacking the

frozen ground. Oh well, I was still happy with the results. It flew and was fun to watch!

Summary:

I would say that it is very overstable and could stand to have some weight removed from the nose. I am unsure about

whether or not the cockpit area has an effect on the flight path, either due to its weight (over 1 ounce) or perhaps

its aerodynamic drag. Either way, there is not much I can do to fix that. I have already repaired it and am anxious for

the next decent day to fly it again!

|

|