Scratch Circle Jerk Original Design / Scratch Built

Scratch - Circle Jerk {Scratch}

Contributed by Drake "Doc" Damerau

| Manufacturer: | Scratch |

Brief:

Brief:

A simple LPR single stage, motor deployed chute recovered tube fin rocket.

Construction:

1 - 24" x 3" BT, 1 24" x 3" BT for fins, 1 chute, 29mm MMT

and 2 CR's, a nose cone, shock cord and a launch lug.

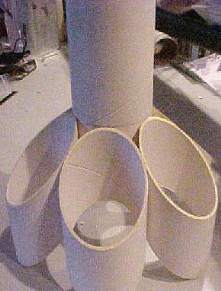

I was asked to write a review on my scratch built Circle Jerk. I hadn't documented any of the construction, so I decided to build another one, but this time I documented the process.

For both birds I used 3" USR "whitewall" tubing because of its thickness. It's twice as thick as any other tubing. I felt that it gives a better appearance to the tube fins.

I cut all of my tubing with a 12" DeWalt compound miter saw. I use a special ripping blade that has more teeth than most blades. This gives a smooth cut that needs very little work. The softer paper tubes do fray a little but that is solved by soaking the ends of the tubes with thin Cyanoacrylate or thinned wood glue. When the glue hardens, just sand the ends to the finish you need. For phenolic tubes, it gives a factory like finish.

The first picture shows the tube being cut and the jig I used. For this

rocket, I made all cuts at a 45-degree angle. The original had just the forward

cut at a 45 and the aft cut at a 90. I just wanted to do something different

this time.

If you use the same diameter tubing for the fins as the body tube, you will need 6 fins. All tube fin rockets work this way. (Do the math) Attaching the fins is elementary. Draw a line around the tube where you want the forward tip of the tube fins to be. Put a bead of glue (I used wood glue) on the first fin and align it on the BT. If you lay it on its side on a table they will be parallel to each other. No more thinking will be necessary because the subsequent fins just lay on the last fin and the BT. For the next fins, just find where the tubes touch, draw a line and put the glue there. The final fin will snuggle up between the last fin applied and the first fin. Use fillets as you see fit, but they are not necessary for strength because each fin is glued at 3 points.

It's tough to find the CP on tube fin rockets like this but it's safe to say that its somewhere in the fin section ;-) Just make sure the CG is forward of the fin section with a motor installed.

Flight:

Flight:

For the original rocket, I used a standard 29 mm motor mount tubes cut to 6

inches. The centering rings (2 of them) were just 5 ply rings I had laying

around. The 32" parachute and the shock cord was from a lawn-darted

Aerotech Astrobee D. The nosecone is a 3" PML. The launch lug is just a

¼" Aerotech igniter tube. (OK, yeah I'm cheap) The final weight is

about 24oz.

For flying, I always use dog barf and friction fit motor retention. She flew straight as an arrow on several F and G motors. Fun to fly.

Summary:

This is a quick and easy rocket to build. Its different than most tube fin

rockets and draws a little attention. Not counting the paint, it took all of an

hour to build.

|

|