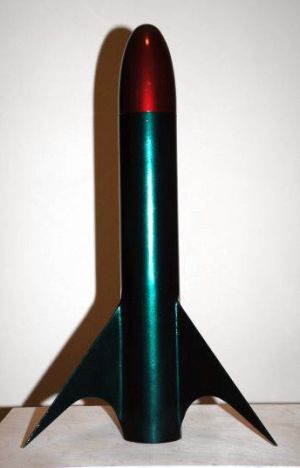

Scratch Dragon's Claw Original Design / Scratch Built

Scratch - Dragon's Claw {Scratch}

Contributed by Joe Policy

| Manufacturer: | Scratch |

Brief:

This rocket was based on a submission for Virtual Contest #4 in the low stress

category. It is easy to build and it is a great flyer.

Construction:

The parts list

- EST 3168 - PNC-80B nose cone

- EST 3090 - BT 80 body tube, 14.25"

- 1 set of laser cut 3/32" birch plywood fins by BMS

- 3 engine tubes, 4" long

- 3 engine blocks

- 2 3/32" birch plywood centering rings for 3 motors

- 2 1/4" x 1" long launch lugs

- 1 24" rip stop nylon parachute from Thrustline Aerospace

- 1 4" square Nomex® heat shield

- 1 24" Kevlar® shock cord

- 24" elastic shock cord

I used Ponal Express 3 white glue for the entire construction with the exception of the epoxy I used for the fin fillets and inside the nose cone.

I needed to add weight to the front end of the rocket to make it stable according to RockSim so I added 8 ounces of sand to the nose cone. I then mixed up 2 ounces of West Systems Epoxy and poured the mixture on top of the sand. I left the nose cone standing vertically while the epoxy cured.

Construction of the actual rocket started with the 3 motor cluster mount. The

rings I purchased from BMS were laser cut, however, I did need to do a little

sanding to get the motor tubes to fit properly. I glued the engine blocks into

the motor tubes so that the E motors would have a 1/2" overhang when

inserted. I then glued on the centering rings 1/2" from the top and bottom

of the cluster. There was a little gap between the 3 motor tubes, I added glue

down the middle to make a perfect seal.

Construction of the actual rocket started with the 3 motor cluster mount. The

rings I purchased from BMS were laser cut, however, I did need to do a little

sanding to get the motor tubes to fit properly. I glued the engine blocks into

the motor tubes so that the E motors would have a 1/2" overhang when

inserted. I then glued on the centering rings 1/2" from the top and bottom

of the cluster. There was a little gap between the 3 motor tubes, I added glue

down the middle to make a perfect seal.

I drilled a small hole in the upper centering ring through which I threaded the Kevlar® shock cord. I tied the Kevlar® around the motor tubes and added glue to the knot. I then inserted the shock cord through the body tube and I glued in the motor mount.

I marked the body tube off for three fins. I glued them 3/4" up from the bottom of the body tube because I did not want the rocket resting on the fin tips. For the fillets, I turned to EMRR Fiberglassing Tip #1 because I wanted really strong fins but since this was not an HPR, I really did not want to go through the trouble of glassing. I purposely made the fillets rather thick so I was able to sand them down to what looked like a sculpted fillet. I think they came out great!

All that was left to do after that was to glue on the two launch lugs, attach the elastic shock cord to the Kevlar®, attach the Nomex® heat shield, add the parachute with a snap swivel, and then attach the nose cone.

Overall, this was about a skill level 2 due to the complexity of the fillets.

Finishing:

To fill the spirals in the body tube, I used Spirals tip #6 from the EMRR tips

database. I added a little water to the Fill 'n' Finish and used my finger to

fill the spirals. After it dried, I used 220 grit sand paper to remove the

excess. There was not a spiral to be seen on the finished product. I used wood

sealer on the fins which required a light sanding and a second coat before I

was happy with the smoothness of the fin surfaces.

I used three coats of Krylon dark gray primer with a 600 grit wet sanding in between coats. I then sprayed the body of the rocket with K Brand Audi Dragon Green metal flake automotive paint. Only one coat was required. I used BMW Red metal flake paint for the nose cone. Once this had dried, I added one coat of K Brand automotive clear coat. The end result was quite nice.

Flight:

Launch day was cloudy with winds at about 2-4 mph. Although I designed this

rocket to fly on E motors, I wanted a shakedown flight using D motors, so I

loaded up 3 D12-7s using spacers in each motor tube. I put a layer of masking

tape on each motor for friction fit. On the first launch all motors lit and it

had it a fast, straight boost to almost 1000 feet. Ejection was very close to

apogee. The parachute deployed and it landed about 200 feet from the pad. No

damage, ready to fly again.

Second flight was with 3 E9-6s. This was a great motor combination for this rocket and it shot to at least 2000 feet with a very straight boost. I lost it in the clouds so I am not sure when ejection occurred. I caught site of the parachute and had a perfect landing about 600 feet from the pad.

It started to rain a bit, so the last flight was back to the D12-7s since I did not want to take a chance on losing it. Last flight of the day was as perfect as the first one!

Recovery:

The Nomex®

heat shield did a great job protecting my nylon parachute.

Summary:

It looks mean but it sure flies well.

PROs: Easy to build cluster rocket and looks good!

CONs: It needs more power so the next one will be 3 x 29mm!

|

|