Scratch Elevate 11 Original Design / Scratch Built

Scratch - Elevate 11 {Scratch}

Contributed by Hans "Chris" Michielssen

| Manufacturer: | Scratch |

Brief:

Brief:

A few years back I was put in charge of finding entertainers for the new Key West area at Sea World in Orlando, Florida. When the word got out, I was getting calls from (too) many entertainers wanting work. One street entertainer drove all the way from Key West for a one-on-one audition. He introduced himself as "Mr. 21." His entire act was based on numerology found on a one dollar bill. He went on and on about how many twenty-ones you could find on a dollar--I couldn't shut the guy up! It was the worst act I've ever auditioned, and it became the inspiration behind my Elevate 11 design.

How many Elevens could I possibly incorporate into a model rocket?

I didn't start with a pencil, paper and ruler to design this project. Initially, I came up with a few obvious "11" ideas. But, I let things stew for a while and kept track of (maybe too many) workable "11" themes.

Construction:

There are 33 "Elevate 11 features":

- Rocket built using an specially designed 11" long ruler, all inches divisible by 11.

- Every rocket component (except for screw eye) Incorporates the number 11, in measurement or markings.

- All rocket construction dimensions divisible by 11.

- 11 sided parachute.

- 11 inches in diameter.

- 11 shroud lines.

- Each shroud line is 11 inches long.

- Tape "disks" were cut from white adhesive backed paper. All pieces were cut to 1.1" x 4/11" long.

- Add 11 streamers down shock cord.

- Each Streamer is 1" x 11" long.

- Each streamer is attached to the shock cord by an masking tape tab that is 1 1/11" square.

- The main body is made up of two Series 11 tubes.

- Both tubes are 11 inches long.

- The tube coupler is 1 3/11" long

- Two launch lugs, both 1.1" long.

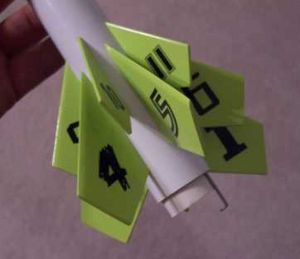

- 11 fins.

- All 11 fins are different sizes

- Fins made from 11 ply cardstock and paper overlays.

- All fins are numbered "countdown" style with decals, 11 to 1 going towards engine end. Fins glued in a spiral pattern.

- 11 Different Fonts, one font style on each fin.

- Engine mount Centering "Ring" is 11/11" long.

- Engine Block is 2/11" wide.

- Engine sticks out back of model by 3/11".

- 11 inches of Kevlar tied to.

- 44 inches of shock cord (four pieces of 11-inch elastic tied together.

- Rocket trim color is light green. On a standard Color Wheel, the color at the 11 O'Clock position is light green.

- Decal stripes beneath Nose Cone joint is actually an eleven applied on it's side.

- Another 11 is included in the EMRR Elevate 11 decal.

- Launch with C11-5 Estes engine.

- Launched on May 2, 2009 at 11:11:11am.

- Count down from eleven.

- Launch button pressed by an eleven year old girl named Emily. (R.O.C.K. section family member.)

- All rocket features--33 in all--are divisible by 11!

(Gawd, do I need a life!)

I ordered one 18" length of the ST-11 tubing from Semroc. Originally the main body of the model was going to be 18" long. I decided to order another ST-11 to make the main tube from two 11" sections of tubing. The outside diameter of the ST-11 tubing is 1.1".

11 ply fins were started. The interior, center-most ply is cereal box cardboard. I cut a straight edge on all sides.

I folded 20lb copy paper down the middle and laid that fold tightly over both sides of the cereal box board. A thin coat of white glue was applied on one side then smoothed with the back edge of a razor blade. I laid down that side and smoothed out the surface with an expended engine casing.

I turned it over and repeated with the other side. All were set between waxed paper and left to dry under heavy books.

By the time I got to the seventh and ninth layers, there was some air bubbles and a little creasing on the smooth surfaces. I plugged in an iron at high heat and I dry pressed the flat sides of the fin material. It helped re-seal the glue layers and get rid of the imperfections.

The fin shape will be cut from the finished 11 layer ply fins. From the middle out:

- Center Layer 1 = Cereal box cardboard

- Layers 2 & 3 = 20lb copy paper folded over leading edge

- Layers 4 & 5 = 20lb copy paper folded over leading edge

- Layers 6 & 7 = 20lb copy paper folded over leading edge

- Layers 8 & 9 = 20lb copy paper folded over leading edge

- Layers 10 & 11 = 110lb cardstock folded over leading edge

The 11" ruler (each inch divided into elevenths) was printed on cardstock and glued over a standard wood ruler. All measurements and construction will be based on the "Elevenths Ruler".

While working on income taxes, I started the engine mount. I cut a scrap BT-50 to 3" long. I cut a notch for a standard engine hook 2-5/11" from the rear of the tube. With the engine hook in this position, the engine will extend 3/11" out the back of the engine mount.

The 2050 centering ring was sanded down to a 2/11" width for the engine block. Kevlar was tied around the end of the engine hook with a tight loop. The knot was set with a drop of glue. After placing the engine hook in it's slot, the 2050 ring was slid into the engine tube from the front. I laid a heavy fillet around the top of the 2050 ring gluing it in place.

Because the ST-11 tube isn't a standard size, no centering rings are available for it. I decided to wrap cardstock around the tube (and engine hook) until I achieved a slide fit into the ST-11 tubing.

A cardstock strip 1-2/11" wide was cut. The wrap was started at the side of the engine hook and 9/11" back from the front of the engine tube. After the wraps were in place and dry, I used a dry, hot iron over the wrapped cardstock to smooth and seal the "centering ring".

There isn't much clearance to pull aside the engine hook out and slide in an engine. I'll glue the engine tube so 4/11" of the tube is out side of the main body. On was made from the remaining ST-11 tubing. I cut a piece 1-3/11" long. The tube was split and slid into the main tube and marked the overlap. I cut off the difference of 3/22" for a slip-fit coupler.

When measured with the eleventh ruler, the BC-1135 nose cone total length (with shoulder) is 4-4/11" long.

The fin ply stock was dry and ready to be cut. I decided on a simple design with each one getting smaller as the eleven fins spiral up the body tube.

The decal design was another story. 11 different type fonts were chosen, one style font for each numbered fin. Every font has a different weight or "boldness". It took some sizing to get all the different styles and numbers visually big enough and balanced on the fin templates.

I'll incorporate a small EMRR Elevate 11 logo copied from the website. The large Elevate 11 name will be set in large capitals running vertically down the length of the body.

A fin spacing template was made in Corel Draw to fit the ST–11 tubing for fins. The uppermost fin will be numbered 11 on top, counting down to number one 1 at the engine.

The fins were cut out--11 layer fins were hard to cut out. The edges were squared with a sanding block. The leading edges were already rounded from folding and laying the overlays over the leading edge. 11 layer fins are almost 1/11" thick and very strong.

The fins got their first coats of gray primer. There is plenty of fuzz to sand off the paper surfaces.

White undercoats were started and work progressed on the decal sheet. I added stripes to the decal sheet art for extra trim, just to be sure. Two of the stripes are actually the elevens from the Elevate 11 font set to run down the body of the rocket.

All eleven streamers were cut. I cut eleven 11" x 1-1/11" crepe paper streamers. With the single parachute, all will be placed side by side down the elastic shock cord.

I was having some problem finding the C11-5 engines. Orlando's biggest hobby store didn't have any in stock. I didn't know that Estes had quit making them. I guess I'm too old school, I fly C6 engines and the next power is a D12. The C11 engines don't come immediately to mind.

I did a few web searches and finally found C11s at the Rocket Garden website in their Estes OOP page. I ordered C11s and a package of B6-6 engines for a staged model in the EMRR Challenge.

Another 11" Kevlar cord was tied to the screw eye in the nose cone. The 44" (total length) shock cord was tied to the upper Kevlar attached to the nose cone. Since this is a mid-body separation, the nose cone is glued into the upper 11" body tube. The nose cone/body tube joint will be filled and sanded for a smooth seam.

The fins are sprayed with gray primer and sanded smooth. White undercoats followed and then Rustoleum Key Lime Green on all. (Key Lime Green is almost the color at the 11 o'clock position on a standard color wheel.) The fins are painted and decals will be applied before gluing to the body.

Two 1-1/11" launch lugs were glued to the body. One at the rear of the lower tube between two fin positions. The upper lug is glued at the base of the upper tube separation.

The main tube and nose cone was sprayed with gray primer and sanded.

Decals were printed. Four coats of clear sealer were applied throughout the day.

Gloss white coats have been applied to the main body. I continued to sand the rough spots on the nose cone before using the green on the top of the rocket.

The 11" parachute was finished and tied to a snap swivel.

The body was masked for the green nose cone. I lowered the masking line below the nose cone/body tube seam (at 5-2/11" from the nose cone tip) to give the illusion of a longer nose cone.

Decals were applied to the body tube and fins. The long Elevate 11 decal was applied in one piece and then cut at the mid-point separation.

Marking the body tube took a little more planning than usual. I wanted the fins to spiral up the body tube.

The main body tube was already finished in white gloss. I marked the body tube for the fins. Using each fin's root edge for a measuring guide, I scraped off a line where the fin would be glued.

The first fin (decaled #1) was glued even with the end of the body tube. I skipped every other alignment line for the rest of the fins. Fin #2 was glued 2/11" up from the rear of the tube. Fin #3 is glued 4/11" from the rear and so on.

There won't be any room to make fillets. Initially I tacked the fins in place with white glue. A bead of CA was run down the joint in place of a fillet.

The assembly drawings were finished. Clear coat was applied over the decal surfaces. All that is left is to attach the parachute and 11 streamers. Launch is scheduled for May 2.

[Click on the following links to download PDFs of the rocket, fins, and ruler.]

Flight:

Flight:

Launch was coordinated with the local Orlando R.O.C.K. NAR section #622 on May 2, 2009. The model was set on the pad 15 minutes early. We would cut into regular launches if necessary, trying to launch at 11:11:11am.

I asked Emily, the only 11 year old at the launch, to press the launch button.

Countdown from eleven was started at 11:10:59am. I instructed Emily to press the button at the word "Launch", not at "one". This would guarantee the ignition would be at 11:11:11am.

I was surprised by the rotation of the rocket body during boost. This had to be from the spiral pattern of the 11 fins.

Boost was straight and ejection was at apogee. The 11" chute opened, but the eleven side-by-side streamers were rolled around the shock cord a bit. No damage on landing.

Summary:

PROs: It was fun coming up with all the Eleven tie-ins. Some may think I went overboard, but wasn't that the idea?

CONs: 11-ply fins are tough to get smooth. There is just too many thin layers. Thin copy paper wrinkles when using white glue. I haven't had this problem with 110lb cardstock fins. 20lb copy paper is harder to work with.

Looking back, I should have done a standard nose blow parachute recovery. Being the body is so long, the recovery system will want to slide inside the main body at launch. This could change the CG/CP relationship. It's hard to load a 11" parachute and 11 streamers in the upper section.

|

|