Scratch Fahrenheit 62/5 Original Design / Scratch Built

Scratch - Fahrenheit 62/5 {Scratch}

Contributed by Larry Brand

| Manufacturer: | Scratch |

Brief:

Fahrenheit 62/5 is a tube fin rocket built simply from PVC plumbing conduit and

designed for durability and good performance on the entire spectrum of APCP

motors having less than 62.5 grams of propellant. It won't fly on any motors

with more propellant than this, or on any Estes BP motors. No, I am not trying

to make a political statement with this rocket. My wife likes this rocket too.

Construction:

Fahrenheit 62/5 is built from PVC plumbing conduit like my larger

F.I.S.H.

design. It is completely waterproof, which puts me at ease when flying it from

our smallish San Diego island launch site. The body is cut from a 17"

section, the optional payload compartment is cut from a 6" section, the

high aspect-ratio tube fins (wider than they are long, unlike most tube fin

rockets) are cut with a 45 degree bevel, 7/8" on the short side and 2

1/8" on the long side. I have been experimenting with tube fin design, and

am finding that high aspect ratio reduces drag while retaining the excellent

stability and balance advantages -- however, high-aspect ratio tube fins create

fabrication problems and have to be made of very strong stuff to resist

crushing. PVC conduit is one way to achieve this. The bevel is partly for looks

and partly to reduce the chance of striking hard ground on a tube fin edge and

cracking it.

Construction of Fahrenheit 62/5 is utter simplicity. There is no motor mount since with some tape fitting, 29mm motors fit exactly into this grade of 34mm OD conduit (24mm motors fit with any of the commercially available adapters).

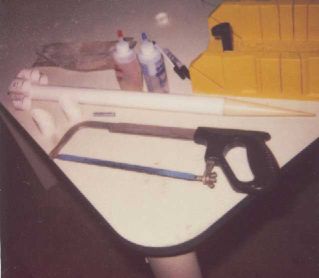

- Using a fine-tooth blade hacksaw and mitre box, cut out the 17" and 6" body tubes and the six 7/8" x 2 1/8" tube fins. Lightly sand the cut edges. Wash the parts with soap and water and then rubbing alcohol to remove any manufacturing residue, which might prevent a good glue/paint bond.

- Rough the attachment areas with sandpaper first. Then attach the 6 tube fins in pairs 1/2" from the aft end of the body tube with 5-minute epoxy (see F.I.S.H. article for specifics on doing this).

- Fabricate the payload compartment "adapter" by affixing an eye-bolt into the nozzle of a spent Aerotech F25 or F50 single use motor. Epoxy this assembly half way into the 6" payload compartment. Cap the payload compartment with a 29mm PML conical polyurethane cone. For flying, both will need a little tape wrap to friction fit perfectly.

- Drill a 1/8" hole about 3" below the top of the body tube and thread 7' of nylon parachute cord through it, securing it with a knot. Cover this knot with a plastic fairing cut from a cigar tube. Secure this shock cord to an eye bolt to complete the recovery and attach a 24" Top Flite chute. Use either a small Nomex® pad or dog barf insulation to protect the parachute.

- Attach a 1/4" x 2" tubular launch lug to a popcicle stick (acting as stand off to clear the tube fin) 3" above the "tube fin can" with it centered with the middle of the tube fin opposite the recovery attachment knot.

Finishing:

I used Testors Lime Pearl spray, which looks great, is easy to find in the

field, but has an "electric" luster that is almost impossible to

capture accurately on film!

Flight:

When flying Fahrenheit 62/5, special attention must be given to preventing

thermal damage to the plastic from the infrared radiant emissions of the

motors. I find that a good way to do this is to simply wrap the motor from top

to bottom in two layers of 3M masking tape before adding the additional tape

wrap needed near the bottom to give the motor a tight fit in the rocket.

Another way to solve this problem is permanently epoxy a length of Estes BT-50

tube slit lengthwise to fit as a liner for the body section. In addition to

friction fitting, I also secure the motor with tape to the inside surface of

each tube fin. I have never spit a motor with this method. I have tested

Fahrenheit 62/5 with the following AT single-use motors: E30-4, E30-7, F21-6,

F20-7, F25-4, F50-6, F50-9, G35-7, G40-7, and G80-10. All of which are good

choices. A drag coefficient of 1.7 +/- 0.1 was obtained was determined using a

Perfectflite Micro altimeter, which is decent for a tube fin design. Maximum

altitude of 2328' was recorded with a AT G40-7 and minimum altitude obtained

was 668' with a E30-4. The rocket can be flown with or without the payload

compartment and no nose weight needs to be added for any motor selection. If

you fly with the payload compartment, secure the nose cone with some masking

tape or the cost advantage of the $2 airframe will be lost along with your

$82.95 worth of altimeter and nose cone.

Summary:

PROs: Fahrenheit 62/5 is a somewhat heavy but great flying sport rocket that

performs on the entire line of Aerotech E-G single use motors. It is extremely

durable and crush proof. Best of all, it goes together in an hour for two bucks

(not counting the $12.95 for the neat PML cone and $8.95 for the chute). It is

waterproof, floats (at least until the vent hole floods the altimeter

compartment!), and is an excellent performer on windy days.

CONs: Weight and inherent tube fin drag limits performance. Where I usually fly, anything hitting 2000' or more will typically splash down in the bay, so this is not an issue for me (F21 or F20 is the largest motor I can use there with this rocket). Length limits motor size, but if you add 3" to the body tube, Fahrenheit 62/5 will accommodate a H128 or H165R, which simulations say will take it to "only" about 2600'. One of these days I think I'll try this.

|

|