Scratch Flatblack Original Design / Scratch Built

Scratch - Flatblack {Scratch}

Contributed by Larry Brand

| Manufacturer: | Scratch |

Brief:

Brief:

I designed Flatblack for the 2004 BRS contest. It is a tubefin rocket that

introduces epoxy-laminated, high-aspect ratio tube fins (wider than they are

long) to take advantage of an aerodymanic trick to power a short, light

airframe with heavy motors. This feature allows the small (18' long, 75 gram)

to fly well on any B-C-D-E-F motors without nose weight worries.

Construction:

Construction is mostly "Estes-like", using the following parts list

as currently available from the BRS website (see "kit" photo):

- 18" BT55 tubing ($1.07 from BRS), cut into a 12" body tube and 6x1" tube fins

- 3x2" BT55 tube couplers ($0.40 from BRS), cut into 1" pieces

- Estes BT55 conical nose cone (the "Black Brant" nosecone), available in the Estes "BT55" assortment pack

- Estes 24mm x 4" motor tube, two 24mmxBT55 "green" centering rings, and 3.75" E-size motor hook (total $1.60 individually from BRS, or purchase the Estes "D&E Engine Mount Kit", which prepackages an assortment

- 24" Kevlar® thread and 3/8" x 36" elastic (total $0.95 from BRS)

- 1/8" launch lug (not larger!)

- 10-12" Mylar or Nylon parachute (the latter a must for E-F power, either as available from BRS

A word about the choice of "high aspect-ratio" tube fins for Flatblack:

This

small rocket has flown successfully on about every choice from B4-2 to F21-6,

with no ballasting or balance adjustments. How is this possible?

This

small rocket has flown successfully on about every choice from B4-2 to F21-6,

with no ballasting or balance adjustments. How is this possible?

Because a tubefin rocket has such a far aft center-of-pressure (Cp), a long heavy motor can actually improvve balance as it moves the CG more forward and further above Cp. With a conventional finned rocket, usually the entire motor casing is below Cp, dropping CG further aft as bigger motors are used, and requiring added nose weight to balance the rocket.

Cp of Flatblack (less than 1" from the tail end) is even further aft than typical for tubefin rockets, by use of the short, high aspect ratio fins.

Nearly all tubefin rockets use low aspect-ratio tubefins; you can see several on the ERMM website. The reason? Short,wide (= high aspect-ratio)

tube fins are flimsy and crush easily unless made of stronger stuff than paper tubing. The tube fins on Flatblack are simple epoxy laminations that are light yet strong, preserving easy construction and the good flying qualities of tubefin rockets while taking advantage of the better performance and motor versatility made possible by high aspect-ratio. Try it and you'll become a believer!

Now, on to Construction:

1) Five minute 2-part epoxy is used throughout. No Elmer's. No Crazy Glue!

2) Assemble the tube fins by epoxying a 1" coupler piece into each 1" BT55 tube fin; these epoxy-laminated tube fins are the key to Flatblck design.

3) Assemble the Estes E-size motor tube per their usual instructions, motor hook inserted into a small slit 3" from the bottom of the tube, sliding the "green" centering rings over the motor hook and epoxying in place 1/4" and 1.5" from the lower and upper ends, respectively.

4) Attach the 6 completed tube fins to the body tube in pairs in self-jigging fashion: glue the first two to the left and right sides, even with the bottom of the body tube, add next pair to the top, and finally the last pair to the bottom, gluing the fins to their neighbors as well as to the body tube. Note: the launch wire has to pass freely through one of the triangular spaces between two of the tube fins, so don't slop these closed with excess epoxy (see unpainted photo)

5) Insert motor tube assembly into body tube, attaching with ample epoxy.

6) Epoxy on the launch lug tube 1.25" above the tube fins and exactly in line with one of the triangular spaces between 2 tube fins (1/8" launch wire required)

7) Use "Estes method" to attach the recovery system to the rocket: tie a small loop (1/2") in the bottom of the Kevlar® section of the shock cord, and epoxy this beneath a small piece of BT55 scrap 1.5" below the top of the body tube; tie the elastic section to the other end. Or, you can use whatever method of attachment you prefer -- if you want to attach the Kevlar® end to the motor mount, you need to do this before gluing the latter in place.

8) Attach the parachute and nose cone to the shock cord 9" apart, in the usual fashion; as always, avoid the preformed loop on the nose cone, and drill a new, second hole in the cone base for secure shock cord attachment.

If your Flatblack will be used even once with 24mm Aerotech motors, you MUST substitute 6' of parachute cord for the 3/8" underpants elastic, and use only the nylon parachute options; Aerotech motors use much stronger ejection charges that Estes products, and will break thin elastic shock cords (See photo of recovery system)

9) Finishing: Flatblack was spray painted with -- what else -- Testor's Flat Black. Mylar lettering spelling out "flatblack" was obtained from Office Depot. (see finished rocket and pad photos)

Flight:

The beauty of Flatblack is its amazing versatility -- It has been flown to date

on Estes B4-2, C6-5, C11-5, D12-5 and E9-4/6 motors, and on AT F21-4 and F21-6

Econojets. What other rocket do you know of (kit or plans) that flies

interchangeably on this range of motors with no ballast changes needed? Just

load it up and fly!

The prefered motor for Flatblack is the Estes E9-4, which gives a fast, straight boost to 1000+ feet even with a bit of wind blowing. Not bad for a slow initial thrust, 62 gram motor in a 75g rocket -- with not a bit of nose weight! The E9-6 is fine also, just gives ejection a touch nose down.

I admit to loosing my first drag race with it, sneaking an E9-6 into the little Flatblack against a kid's C6 model -- musta been a delayed ignition (see photos). But Flatblack kept going and going and going after the C6 ejected.

Using an 18mm adapter (Vaughn Bros.), Flatblack has flown on as small as an Estes B4-2, giving a slow but straight clim b to about 175' with perfect ejection.

Out in the desert, Flatblack was flown on AT F21-4 and F21-6 motors -- screaming climbs out of sight (my sight, anyway) to at least the 1350' and 380 mph predicted by sims. I love that huge F21 flame!

For smaller fields, Flatblack files perfectly on C11-5 and D12-5 24mm Estes motors, ejecting perfectly and in good agreement with the 375' and 625' boosts predicted by sims.

Incidently, a drag

coefficient of 1.7 was used for the simulation software, based on an identical

value obtained using altimeters with Flatblack's similar big brother,

Fahrenheit

62/5.

Incidently, a drag

coefficient of 1.7 was used for the simulation software, based on an identical

value obtained using altimeters with Flatblack's similar big brother,

Fahrenheit

62/5.

I haven't tried any of the 24mm, AT reloadable motors yet, but based on their weight of 60 grams, good choices should be: E18-4/7, F24-4/7 and especially the F12-5, according to sims.

After more than a dozen test flights, Flatblack shows not a bit of damage (see landing photo). This little guy is a lot of fun, and you can fly it on anything.

Summary:

PROs: Novel looks, good performance and low-cost construction. Easy to scratch

build, even for beginners. Durable, fins don't break off. Good stability and

wind resistance. Amazing range of motors possible, B-C-D-E-F with no balance

worries. Doesn't go so high on F-power that loss is likely.

CONs: The price of all the PROs is the twice the drag of a "normal" rocket, although Cd=1.7 is still pretty darn good for a tubefin.

Sponsored Ads

-

Vintage Estes Mini-Engine

Adapter - eBay Auction -

Current Bid: $0.99 (Bids: 0) -

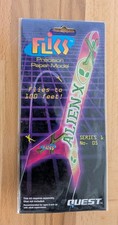

Quest Flics Paper Rocket

(OOP) - eBay Auction -

Current Bid: $0.99 (Bids: 0) -

Estes Alpha VI (OOP) - eBay Auction -

Current Bid: $20.50 (Bids: 17) -

Estes Screaming Eagle #2117 New Flying Rocket

Kit - eBay Auction -

Current Bid: $25.00 (Bids: 13) -

Eagle Aerospace Systems Vintage Advertising

Letter - eBay Auction -

Current Bid: $0.99 (Bids: 0) -

Semroc Micron (OOP) - eBay Auction -

Current Bid: $6.50 (Bids: 3) -

PNC-80K Plastic Nose Cone (Package Of

10) - eBay Auction -

Current Bid: $22.50 (Bids: 8) -

Estes Space Racer (OOP) - eBay Auction -

Current Bid: $2.99 (Bids: 0) -

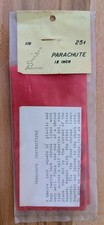

Vintage Estes Plastic

Parachutes - eBay Auction -

Current Bid: $0.99 (Bids: 1) -

Space Age Industries Vintage Plastic

Parachute - eBay Auction -

Current Bid: $0.99 (Bids: 1)

|

|