Scratch Great Googly Moogly Original Design / Scratch Built

Scratch - Great Googly Moogly {Scratch}

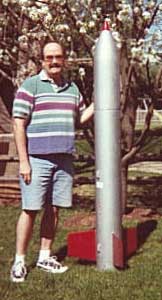

Contributed by Dick Stafford

| Manufacturer: | Scratch |

Brief:

Brief:

The Great Googly Moogly is a 8" x 75" scratch built rocket that I

used for my TRA Level 2 certification at LDRS 19 in Orangeburg, SC. However, I

began building it almost a year earlier, before even getting my Level-1 cert.

Many of the building techniques used were new to me, and a few were

unconventional. However, the results have been satisfying.

Construction:

This fat stubby rocket has one 8" body tube, a large glassed Styrofoam

nose cone, three semi-removable (see below) plywood fins, an altimeter bay, and

a 3" motor mount and held in by 3, 1/2" plywood centering rings. The

recovery system includes 25' of 3/4" tubular nylon, a Rocketman R12C

chute, and (optionally) a Pratt G-Whiz Deluxe accelerometer/altimeter. For my

L2 cert, I built a 38mm motor mount adapter.

Airframe: This is what started it all. I discovered an

8.125" x 48" section of Quik Tube (I think that was the name) at Home

Depot. I did a LOT of sanding to get rid of the spirals and the results were

not too bad. The fin slots were routed with a Dremel. Later, I fiber-glassed

the top foot of the tube to protect against zippering. Probably should have

done the whole tube to start with. So far, this has proven to be unnecessary

structurally, but finishing would have been easier. The launch lugs are

3/4" Acme conformal lugs for 7.5" tubing. I sanded these to fit the

larger airframe and glued them on with CA.

Airframe: This is what started it all. I discovered an

8.125" x 48" section of Quik Tube (I think that was the name) at Home

Depot. I did a LOT of sanding to get rid of the spirals and the results were

not too bad. The fin slots were routed with a Dremel. Later, I fiber-glassed

the top foot of the tube to protect against zippering. Probably should have

done the whole tube to start with. So far, this has proven to be unnecessary

structurally, but finishing would have been easier. The launch lugs are

3/4" Acme conformal lugs for 7.5" tubing. I sanded these to fit the

larger airframe and glued them on with CA.

Nose Cone: The nose cone was fabricated from slabs of pink foam insulation that were glued together with polyurethane glue. I learned to be sparing with this stuff as it expands quite a bit while it cures. Despite placing weight on this "sandwich" while the glue dried/cured, the slabs separated in places by as much as ~1/8". On both ends, I glued in sections of 1/2" dowel and, on what was to be the back end, a home made plywood bulkhead was epoxied on. The shape was partially roughed-out by hand but the majority of the shaping was performed on a lathe at a local high school (my thanks to Dean and his students!). The tip of the nosecone didn't turn out well so I epoxied on a section of a Styrofoam cone purchased from a craft store. The whole nose cone was then covered with a layer of heavy fiberglass (weight unknown) from a hobby store. This was my first try at fiberglassing anything of any size and it was a mess. I gave up on making the cone really smooth but did fill the weave and some of the imperfections with Elmer's Fill 'n Finish. Later, to adjust the CG, I screwed 4 large lag bolts into the side of the nose. The remnant holes were filled with Fill 'n Finish, and then patched with fiberglass. An 8" eyebolt was epoxied into the center of the bulkplate.

Motor mount: I wanted to be able to use several sizes of motors

so I opted for a 3" x 30" main motor tube. A full 36" tube

didn't appear to leave enough room for the chute, so I went for 30". This

tube, along with three 7.5" x 1/2" centering rings (CRs) were bought

from Giant Leap. The front CR is at the top of the motor tube and the bottom

two frame the fins. Since these CRs did not fit the airframe, some improvising

was required. For the front ring, I built up the edge with a many wraps of

fiberglass (honeycomb) wall board tape. This structure was filled with epoxy.

This tape has a lot of void space so a lot of epoxy was required. The result

seemed very sturdy, but was quite heavy. For the rear two rings, I glued wooden

shims to the inside of the Quik Tube using carpenter's glue. The middle ring

was epoxied in and the rear one was held in with wood screws.

Motor mount: I wanted to be able to use several sizes of motors

so I opted for a 3" x 30" main motor tube. A full 36" tube

didn't appear to leave enough room for the chute, so I went for 30". This

tube, along with three 7.5" x 1/2" centering rings (CRs) were bought

from Giant Leap. The front CR is at the top of the motor tube and the bottom

two frame the fins. Since these CRs did not fit the airframe, some improvising

was required. For the front ring, I built up the edge with a many wraps of

fiberglass (honeycomb) wall board tape. This structure was filled with epoxy.

This tape has a lot of void space so a lot of epoxy was required. The result

seemed very sturdy, but was quite heavy. For the rear two rings, I glued wooden

shims to the inside of the Quik Tube using carpenter's glue. The middle ring

was epoxied in and the rear one was held in with wood screws.

I originally built a 3 x 29mm motor adapter, but quickly realized that 3 G80s would not lift this beast. I then built a 38mm adapter from centering rings and phenolic tubing. This adapter has positive retention (bolts and washers) to the rear CR, and itself holds aluminum motor retainers for the 38mm RMS casing. To support the adapter, I installed a 38mm centering ring and a short section of coupler tube in the top of the 3" motor tube.

Fins: The fins are 1/4" plywood that was scrap from the high school wood shop. I was worried about breakage upon landing, so I mounted them so they were easily replaceable. They are bolted to brackets on the main motor tube but are epoxied to the airframe, with inner and outer fillets. If a fin needs replacement, I can cut the fin out of the airframe, remove the rear CR, and unbolt the remaining section of the fin. There is just enough room between the motor tube and the airframe to reach the innermost bolts. As with the airframe, I probably should have glassed the fins. They are recessed from the aft end of the rocket and are swept slightly forward. So far, the large Rocketman chute has done its job and the fins have survived.

Altimeter bay: I found a 2" mailing tube with an inner

telescoping tube. I cut a section of the outer tube and epoxied it against the

airframe and front CR. I then used a section of the inner tube to build an

altimeter bay. A plywood bulkhead is epoxied on one end of the tube. A section

of All-Thread is bolted to this plate and runs the length of the bay and

through the top bulkhead cap. This All-Thread is off-center to provide more

space for the electronics, which in this case is a G-Wiz deluxe altimeter

purchased from Pratt Hobbies. To mount the altimeter, I cut a rectangular

section of G10 that slides into the bay. I attached a 9V battery holder and an

expended 13mm motor casing. The latter slides over the all thread to give

additional support. The top cap also holds screw terminals (banana plug type).

A wing nut tightens the assembly together. When closed tightly, the electronics

are fully isolated from ejection gasses.

Altimeter bay: I found a 2" mailing tube with an inner

telescoping tube. I cut a section of the outer tube and epoxied it against the

airframe and front CR. I then used a section of the inner tube to build an

altimeter bay. A plywood bulkhead is epoxied on one end of the tube. A section

of All-Thread is bolted to this plate and runs the length of the bay and

through the top bulkhead cap. This All-Thread is off-center to provide more

space for the electronics, which in this case is a G-Wiz deluxe altimeter

purchased from Pratt Hobbies. To mount the altimeter, I cut a rectangular

section of G10 that slides into the bay. I attached a 9V battery holder and an

expended 13mm motor casing. The latter slides over the all thread to give

additional support. The top cap also holds screw terminals (banana plug type).

A wing nut tightens the assembly together. When closed tightly, the electronics

are fully isolated from ejection gasses.

Finishing:

I painted the body and nose cone with Rustoleum 'hammered' silver to hide some

of the finishing flaws. The tip of the nose is painted red. The fins were

covered with burgundy Monokote. This was the first time I had used this

material. From a distance, the rocket looks pretty good.

Flight:

The recovery system includes 2 u-bolts on the front centering ring, connected

with a section of 1/2" tubular Kevlar® (Giant Leap). The shock cord is 25'

of 3/4" tubular nylon. All of these components are connected with

quick-links. The chute is a Rocketman R12C. Recovery protection is provided by

Nomex® pads and a Nomex® shock cord cover (also from Giant Leap). This all packs

easily in the large airframe. As mentioned above, the use of an altimeter is

optional.

Flight #1. The first flight was on an I211-S under the name 'So-So Fat', and was quite underpowered. The rocket rose to only a few hundred feet and the NC drag separated. The motor ejection charge fired shortly afterwards. Recovery was nevertheless perfect - but everyone laughed at how underpowered the flight was. This prompted me to rename the rocket 'Needs Viagra'.

Aside: While planning my trip to LDRS and my Level-2 attempt, I picked up a copy of an old Frank Zappa album (Apostrophe) on CD. This in turn prompted me to rename the rocket 'Great Googly Moogly'.

Flight #2. The second flight was on a J350-M and made use of my G-Wiz Deluxe altimeter. The motor ejection charge was a backup since this was the first attempt at altimeter-based deployment. I also used an ejection canister from Pratt Hobbies. This consists of a small plastic container with an integral cap and includes an electric match with about a yard of lead wire. The canister was inserted into a short section of copper tubing, which was installed in the top of the 3" tube. One leg of the lead wire was run through a hole in the airframe, cut, and stripped. At the pad, this connection was twisted back together and reinserted into the airframe.

On the first push of the button, the igniter failed. On the second, the Great Googly Moogly rose majestically into the sky. The chute ejected at apogee and it returned safely. The altimeter reported 1531 feet. Level-2! YES!

Summary:

Summary:

The main Pros of this rocket are: overall looks (I love FAT rockets);

flexibility (38mm - 76mm motors, optional electronic ejection); maintainability

(fins easily replaced); can see the entire flight on a J350.

The Cons are: fins may not hold up to bigger motors

Other:

This large scratch project was completely successful and taught me a lot. One

thing that it taught me is that big rockets are expensive. Even though I got a

cheap airframe, built my own nose cone, got free fin material, I still spend a

bucket of money. Big chutes are expensive!

|

|