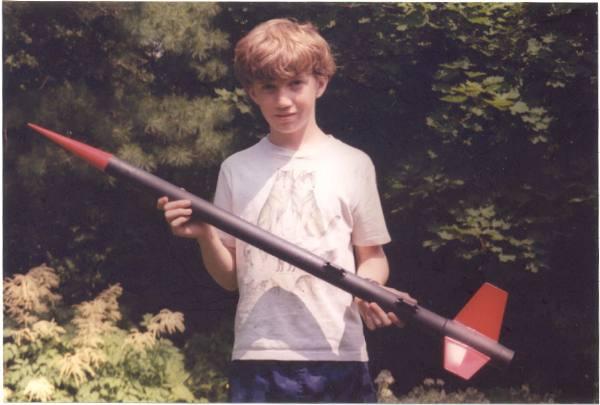

Scratch Mach Buster 1 Original Design / Scratch Built

Scratch - Mach Buster 1 {Scratch}

Contributed by Neil Thompson

| Manufacturer: | Scratch |

Brief:

This is a single staged HPR capable rocket. It can use anything from a big E to

a J570. It can easily break Mach 1 on an H, and can reach Mach 2 on a J.

Construction:

The Mach Buster 1 uses a fiberglassed phenolic airframe, PML solid urethane

nose, Acme fin can and launch lugs, Kevlar®

heat shield and shock cord, a Slimline circle ring motor retainer, and an

optional Slimline motor adapter. I suppose you could put a payload section on

for altimeters and dual deployment.

This was a very easy build. I used 2-ton epoxy throughout. I got all the parts besides the nose cone and fiberglass cloth from Giant Leap Rocketry. The nose cone I got from PML, the fiberglass I got from a hobby shop. After I fiberglassed the tube, the fin can fit exactly. The launch lugs liked to slide around while the epoxy is drying, but other wise it was easy. The fins needed no alignment, besides lining up with the launch lug. I taped and epoxied the shock cord to the body tube. After I completed the construction I painted it red and black. Red on the fins, and red on the nose cone, but black on the body tube and part of the fin can and Slimline. Overall, this is a very sturdy rocket — it could survive a tar landing easily.

Flight:

Flight:

I still have not flown this, but I am planning on flying it on labor day 2003.

The first flight will be on an F50-9T, the next on a G35-7W, and the next on an

F20-7W. I put in a home made parachute. It is a very large parachute, but I

will reef it on breezy days. It is over stable, according to Rock-Sim and

SpaceCAD. All simulations show straight flights, high (approx. 3250' on

F’s and G’s), and fast, despite the weight.

I got two flights in on this rocket on labor day 2003. The first flight for this rocket was also my first blue thunder propellant motor, and I was rather impressed by the performance. It could have had more smoke, however. The motor was an F50-9T. The second flight was a G35-7W, and it flew like the wind! And that is saying something, considering the gusts there! At least there are seemingly endless blueberry barrens for the rockets to land in. Both flights were straight as an arrow. It had a Kevlar® heat sheild, eliminating the need for wadding. I also installed a Slimline motor retainer to hold my motor in. This worked very well. There was no damage to the parachute after either flight, however, one of the shroud lines on the parachute got tangled in the screw eye that I used to attach the shock cord to the nose cone, causing a tumble recovery. Hardly even had a scratch in the paint. This is such a rugged rocket. Anything else that size falling from that height I would expect to crumple.

Summary:

Tough as anything. I suspect that thing could be hit by lightning and survive,

or at least it could be stepped on or kicked around.

Pros: I love this rocket. I consider it a work of art. It is easily the best of my fleet (that is saying something). It goes high and fast, can survive hard landings, and requires zero fin alignment (A definite + for me! I hate aligning surface mounts on large rockets). Easy build.

Cons: Price. $80. OUCH if you are 12, and I should know. Worth every penny though.

Other:

DO NOT LEAVE THE AIRFRAME SITTING ON A PICNIC TABLE WHILE THE EPOXY AND

FIBERGLASS IS SETTING! YOUR MOTHER (or wife) WILL NOT LIKE IT.. I learned that

the hard way. It took a lot of sandpaper to get it nice again.

|

|