Scratch MicroFoam DARockeT Original Design / Scratch Built

Scratch - MicroFoam DARockeT {Scratch}

Contributed by Scott Turnbull

| Manufacturer: | Scratch |

Brief:

Brief:

Converted a Generic Foam Dart to MicroMaxx Power. I hereby dub thee a MicroFoam

DARockeT.

Modifications:

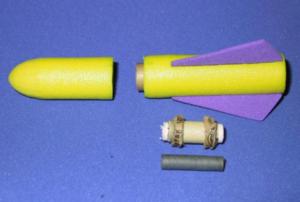

A length of barrel was cut from a round pen to form a motor mount tube. Two

1/8" wide centering rings were cut from the "A" casing. The tube

was wrapped in masking tape until the rings were a snug fit. The centering

rings were CA'd to the MMT. The end plug from the pen was inserted into the MMT

to provide blockage for positive engine ejection. The MMT was CA'd into the

tail of the foam dart. The forward third of the dart was cut off with a razor

knife to provide access for nose weight. A 1" length of "A"

casing was used as a coupler of the dart tip to the tail section. A length of

ink tube from the pen was cut and taped to the side of the MicroFoam DARockeT

to serve as a launch lug.

Construction:

This Custom Modification includes:

- Generic 4.5" hollow foam dart with fins

- Round Barreled BallPoint Pen

- Spent "A" Class Engine Casing

- CA Glue

- Clay

- Cellophane and Masking Tape

This was a seemingly simple

conversion, but not without its challenges. The centering rings were so narrow

that they started to unwrap during handling. They were kept small to reduce the

overall weight and optimize performance from the MicroMaxx engines. Gluing the

forward ring in place within the main body was unreliable, so extra CA was used

to bond the rear ring thoroughly to the foam tube. The ink tube launch lug was

a perfect diameter for the MicroMaxx Launch System Rod. Finding a glue to hold

the slick lug to the foam proved problematic, but a piece of cellophane tape

made for a secure mount.

This was a seemingly simple

conversion, but not without its challenges. The centering rings were so narrow

that they started to unwrap during handling. They were kept small to reduce the

overall weight and optimize performance from the MicroMaxx engines. Gluing the

forward ring in place within the main body was unreliable, so extra CA was used

to bond the rear ring thoroughly to the foam tube. The ink tube launch lug was

a perfect diameter for the MicroMaxx Launch System Rod. Finding a glue to hold

the slick lug to the foam proved problematic, but a piece of cellophane tape

made for a secure mount.

Flight:

Flight:

The new, more powerful, MicroMaxx Motors were used. These are listed as 300 Mil

N-Sec, and claim 120 feet Max Altitude. This proved too much thrust for a

MicroFoam DARockeT without additional nose weight. It rose about 10 feet and

flopped about before ejecting the engine and safely executing a Boink recovery.

Clay was used to fill the "A" casing nose coupler, and a second

launch yielded a stable thrust with a slight arc-over. The engine ejected, and

the DARockeT coasted to spec-busting altitude. The DARockeT crossed over the

road and landed on the neighbors front stoop. The nose piece separated during

the Boink maneuver. For the third flight, a piece of cellophane tape was used

to bind the tip to the tail. Another stable thrust and ejection sent the

DARockeT soaring over the neighboring trees. The streamlined nature of the

BOINK recovery system allowed the DARockeT to slide through the dense foliage

and land unharmed.

Summary:

In summary, this modification explores the top end of the performance envelope

defined by MicroMaxx Motors. The BOINK recovery system provides maximum

altitude via ballistic coasting, while maintaining a sleek profile for foliage

foiling. To sum it up in two words. It's FUN!

|

|