Scratch Moldy Crow Original Design / Scratch Built

Scratch - Moldy Crow {Scratch}

Contributed by Peter Smith

| Manufacturer: | Scratch |

Brief:

Brief:

A 29mm minimum diameter rocket.

Construction:

- one 30" length of PML 29mm tubing

- one 29mm PML conical nosecone

- one "Econo-Jet spacer" for motor block

- a small sheet of 1/32 inch G10 fiberglass

- 7' of small tubular Kevlar® from Pratt

- one 40" by 2" Mylar streamer

- one 6" square Nomex® heat shield

I wanted to make rocket that could break the sound barrier using a G motor like the old Rocketvision Mach Buster. Unfortunately that kit is no longer available and the G55's that boosted it are hard to find so there was no point in cloning it. I then tried looking for a G125 motor; however, I couldn't find any for a reasonable price so I decided I would have to design a minimum diameter rocket that could break the sound barrier on a G80 motor.

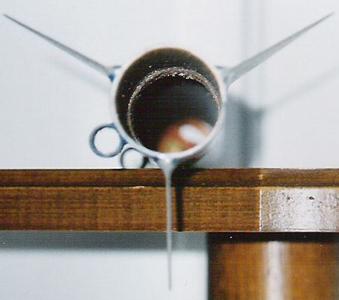

I fired up RockSim and soon I came up with a good high performance design that would be 30" tall by 29mm diameter with little three sided fins. I decided to use a Public Missiles 29mm nosecone and airframe because they were already compatible with each other without any sanding. Also, I needed that heavy 2oz resin cone to keep this thing stable (RockSim actually says it's over stable with a G80 loaded). I just had to cut the tube to 24" in length and it was good to go.

I then bought a sheet of 1/32" thick G10 fiberglass from Vaughn Brothers for the fins. I took the fin measurements from RockSim (3.5" length by 1.5" height at the tip, which is .75" from the back) and drew it on the fiberglass. I used my Dremel with a right angle attachment and a cutting wheel and soon I had three nicely cut triangle shaped fins. I then put a sanding drum on the Dremel and put a sharp double wedge airfoil on them.

Next I filled the airframe spirals with Fix-It epoxy clay which took a while because it was rather slow going. Once all the spirals were filled I sanded the airframe and marked it for three fins using the fin alignment page in the Handbook of Model Rocketry. I then attached the fins using USA Gold CA after which I filleted them with West System Epoxy with colloidal silica. At the same time I epoxied the Econo-Jet spacer come motor block into the rear of the airframe using a G80 casing for spacing. I wanted the motor as far up as possible to keep the rocket stable, although I had it stick out a 1/4" just so you had something to grab onto for removal.

After that I used about one foot of the Kevlar® and some epoxy clay to make a "LOC style" shock cord mount. The rocket was essentially done after that, I just cut a 40" by 2" section of the Mylar that I bought from Apogee Components and cut a small 1/8" slit at the top and stuck a hole reinforcement on both sides of it. I then tied a loop of Pratt micro-braid Kevlar® through the slit and I had a streamer.

For the launch lugs I cut two 1" sections of the quarter inch tube that Aero-Tech puts igniters in. I was going to use ACME conformal lugs but they seemed too big for a little rocket like this. I CA'ed one lug in between two fins 1 1/2" from the bottom of the rocket. I then put a 1/4" rod through the bottom lug and lined it up with the tip of the nose cone and marked lines on either side of the rod with a pencil. I removed the rod and CA'd the upper lug between the two lines I just made and 9" up from the bottom lug. I also put small West System fillets on them for reinforcement and to reduce drag.

Also, I didn't think about it until I was almost done but due to the speed/altitude factor there was a possibility that the nosecone might pop off due to the rapid decrease in air pressure. So to prevent this I simply drilled a 7/64" (any similar size would work) hole in the airframe and lightly sanded it to remove any burrs.

I painted the rocket with Krylon Regal Blue and Stone Gray (my signature colors). I made the airframe blue and the nosecone and fins gray; very simple. I dubbed the rocket the Moldy Crow as a joke.

Flight:

Flight:

I didn't have long to wait to launch it, because the next PARA launch a was

perfect; low wind and few clouds which is rare in Pennsylvania. I decided to

use some marking chalk in the it due to its RockSim predicted altitude of

4,500' at a speed of 900 mph. I used some red chalk line type chalk which I put

in a tissue and twisted the ends to make a little pouch that would keep the

mess in the air (it stains everything).

Once I launched another rocket to test the wind conditions I put a G80-10T with Magnelite in the Moldy Crow and set it up on a pad. As the LCO called out the motor, people looked at the little rocket which looked like it was designed for Estes D12's at most. And with a name like "Moldy Crow" and the fact that it was the first flight, people were not sure what to make of it. When the LCO pressed the launch button the Crow exploded off the pad and all I saw was a light gray smoke trail that just kept going. I couldn't hear a sonic pop but at that speed I'm sure it broke Mach 1 like RockSim said.

People were pretty impressed by that flight, especially some of the newer members. Although there was still the matter of getting it back, which was the second thing in mind when building this kit. I could clearly see the red cloud of chalk which was slowly drifting down range. It was then I caught a glimpse of light reflecting off of the streamer. The occasional shine of light was the only way I knew where it was because it was too high to see the rocket or even the entire streamer. It gradually came down to where you could see it clearly and you could see how fast it was going (approx. 40fps).

Then I lost sight of it behind the line of trees I was standing next to, but I had a good idea where it went. I walked along until I came to the end of the trees and I could see into the cow pasture and there it was sitting right on top of the churned up dirt. I slipped through the barbed and electric wire fence and retrieved the Moldy Crow, luckily the cows were in the barn at the time or they may have been a problem. But I got back through the fence and inspected the rocket. It was cover in mud and red chalk but besides that it was in fine condition, however half of the streamer's length was tattered to nothing but little shreds of Mylar. I figured this must have been do to its high speed decent. Overall this was a very successful flight.

Summary:

Pros: relatively easy to build very rewarding to fly

Cons: PML nosecone makes this an expensive loss, takes a while to fill airframe spirals, hard to spot in the air, hurts neck to watch it launch.

Other:

I think this is a great rocket for those of you who love high speed/altitude

flights. If you wanted more speed less altitude you could use a G40 motor. I

also built a cheaper version using LOC 29mm tubing and an Estes NC-55 nosecone.

Although, you have to cut the shoulder and a lot of the cone off to make it

flush with the LOC tubing. I made the new shoulder out of a Econo-Jet spacer. I

then had to add 1.8oz of BBs and clay to make it equal to the PML nosecone.

Other than those changes it is the same kit with the same performance but it is

a little cheaper.

|

|