Scratch Night Hawk Original Design / Scratch Built

Scratch - Night Hawk {Scratch}

Contributed by Donald Besaw Jr

| Manufacturer: | Scratch |

Brief:

Brief:

This is a rocket that I designed for small fields. It is single staged, flies

on Estes A10-3T motors to about 200 feet and uses a streamer for recovery.

Construction:

Materials required:

- 2 Estes BT-20 body tubes

- 2 Estes NC-20 nose cones (Yankee Style)

- 1 Estes NC-20 nose cone (Viking Style)

- 1 Estes Mini Motor Mount Kit or make your own.

- 1 sheet of medium 1/16 or 3/32 balsa for fins (your choice)

- 1 standard launch lug

- 1 shock cord mount

- 1 shock cord about 2 to 3 feet long

- 1 streamer

- 1 pack clay nose weight possibly

Optional Parts:

- 1 Estes BT-20 tube coupler

- 1 Piece balsa cut to fit inside coupler

- 1 small eye bolt

This rocket is fairly easy to build, however I would rate it a skill level 2 project. If you've built several Estes Beta kits, you should have no problems. Supplies Required:

- White or yellow glue

- Hobby knife with several #11 blades

- Sandpaper #320-400 grit

- Masking Tape

- Pencil

- Ruler

- Sanding Sealer (optional)

- Automotive Primer (white or gray) (recommended)

- Spray Enamel (your choice)

Start by cutting two 4/5/8 sections from one tube and sand the cut ends even. These are now your side pods. The fins will be attached to these later. Now cut the main tube to a length of about 14 inches and sand the ends even.

Optional Step for dual recovery: Cut the main tube in half and sand the ends even. Now glue the coupler halfway into the upper tube. After the glue dries, cut a bulkhead to fit inside the coupler. After the glue dries, carefully screw a small eye bolt into the center of the bulkhead.

Glue the side pods one at a time with the ends flush with the end of the main tube. Once the glue is dry, you can apply glue fillets to the side pods. Make sure to fill as much of the gaps as possible.

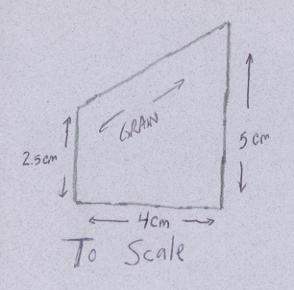

You may want to cut out your

fins at this time. Make six fins with a 1 9/16 inch long root edge, a 1 3/4

inch long leading edge, a 1 inch trailing edge, and a 1 1/2 inch bottom edge.

Take a piece of sandpaper and stack sand the fins to size. Now sand the leading

and trailing edges round.

You may want to cut out your

fins at this time. Make six fins with a 1 9/16 inch long root edge, a 1 3/4

inch long leading edge, a 1 inch trailing edge, and a 1 1/2 inch bottom edge.

Take a piece of sandpaper and stack sand the fins to size. Now sand the leading

and trailing edges round.

Assemble your motor mount at this time. After the glue is dry, insert it with the motor tube flush with the body tube.

You may attach the fins at this time. Three fins are attached to each side pod at an angle of 90 degrees apart like a typical four fin design. Heres a tip to make for an easier attachment. Apply a film of glue to the root edge of a fin, let dry for a minute or two, apply another film of glue then attach. Believe me, this works. Now apply fillets to each fin. I recommend three fillets per fin.

Cut a standard launch lug into two 1/2 inch pieces. Attach one to the bottom of the body tube flush with the end. Attach the other one about 7 1/2 from the other one then align them with a launch rod. If you opted for a dual recovery, apply the last one flush with the bottom of the upper tube. After the glue dries, apply fillets at each lug. I recommend about two fillets per lug.

Cut yourself a shock cord mount from computer printer paper or typing paper. I do not recommend notebook paper. I have used this method on all of my scratch designs and it hasn't failed yet.

You will need a shock cord at least 2 feet long. Now assemble the mount in the traditional manner. Once the glue has dried, glue the mount at least 1/2 an inch from the top of the tube.

Now is a good time to test fit your nose cones. You want a nice snug fit. If they are too loose apply masking tape at the shoulders or glue them in place after the model has been balanced and painted.

Now is an excellent time to balance the model. Balance the model on a straight edge or counter-top. When the model hangs level draw a mark at that spot. Now tie a six to eight foot string to that mark. Swing the model around you and note the results. If the model flies straight its fine. If it flops or wobbles irregularly, chances are that you will need nose weight. My model required nose weight. Add enough weight until the model balances out. That should do it.

Now you are ready to finish the model.

Finishing:

Start by sanding the model smooth. Apply sanding sealer if desired. Sand

between coats. Now spray the model with automotive primer. Sand any

imperfections. Then apply another coat. Sand if needed. Now go ahead with your

planned color scheme. After the paint has dried, you may attach the streamer.

An easier way is to tie a six inch string to the streamer then attach that to

the nose cone insert or the eye bolt. Now lets go to the field and see how she

flies.

Flight:

If built stock, the only motor that I recommend is the Estes A10-3T. This motor

gives the model a nice boost and ejection usually occurs right at apogee. I

used friction fit retention on my model and it worked perfectly. For my

flights, I used the Estes A10-3T motor and two squares of recovery wadding to

protect the streamer. All three flights were perfect and straight with a little

spin but for me that added to the excitement. The model comes down very nicely

with the streamer. I used the dual recovery method. My model bounces on landing

but with all the fillets that I applied, it hasn't sustained any damage.

Summary:

When I designed this rocket and after flight testing, my goal was to share this

design with others. I really have enjoyed this model from planning the design

to pushing the launch button for the first launch.

Main PROS: Small, extremely easy to transport, flies on low cost mini motors, five bucks for four flights is not bad at all. Flies great on small fields.

Main CONS: A lot of components are required but if you buy an Estes Designers Special package, you will get all the components except the main nose cone and the motor kit but you can easily buy these at any hobby shop.

Other:

I also feel that the rocket could be modified to fly on standard 18mm motors or

fly on three mini motors but watch out. Also, use 3/32 fin material if you try

this. Also, more nose weight may be required.

|

|