Scratch Phoenix BT-60 Original Design / Scratch Built

Scratch - Phoenix BT-60 {Scratch}

Contributed by Marlin Meyer

Brief:

Single stage BT-60 version of Launch Pad's Phoenix missile. Recovery via parachute.

Construction:

These are all Semroc numbers:

- BNC-60V balsa nose cone

- SE-3 screw eye

- BT-60 body tube - 13.2 in long

- RA-2060 centering ring used as a parachute shelf

- 2 LL-423 launch lugs - 1/4 x 2.25

- BT-20 engine tube - 3 in

- 2 RA-20 60 centering rings

- EH-28 engine hook

- EB-20A engine block

- 12" RocketChutes Rip stop nylon parachute

- 100 lb Kevlar® shock cord

All parts were ordered from Semroc. Nothing fancy about the build. Here's the sequence I use:

- build the engine mount

- apply sealer to nose cone - I use Elmer's

- print fin pattern from Rocksim, glue to cardboard, cut with Xacto

- use pattern to mark fins

- cut fins, sand in a stack, then paper both sides. I'm a big fan of this because it is easier and makes the fins stronger. I sandwich the fins between two pieces of glass and place weight on them over-night.

- lightly sand the entire body tube and mark 4 fin pattern line the entire length of the tube. Also mark lines to show where back of forward fins are to be placed - 54mm from base (optional: drill 4 1/8" holes on the fin lines to allow for altimeter)

- attach shock cord to engine mount and glue engine mount in place

- trim paper around fins and sand edges

- glue rear fins

- glue forward fins

- fillet all fins

- cut launch lugs to 1 inch length and then each end to 45 degree angle

- glue launch lugs at the fin/body tube seam.

- fillet launch lugs

Finishing:

- entire rocket primed with Rustoleum sandable auto primer and left to dry over-night.

- entire rocket sanded using #300 paper. Pay careful attention to fin edges!

- Three coats Krylon white. I've built some Phoenix rockets with gray body, but I wanted the decals to really stand out, so I went with white on this one.

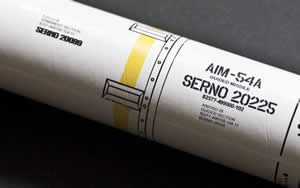

- I purchased a set of decals from Stickershock specifying them to be scaled to fit BT-60. The decals were beautiful. Even the smallest lettering was clear.

- I attached a small fishing swivel to a 12" chute and made two loops in the shock cord. One for parachute attachment and the other for Altimeter One attachment.

Flight:

The 12" chute brings the rocket down about 21/fps. I flew only Estes black power motors.

All three flights were on the same day. Sunny, 80 degrees, and very still. "Dog barf was used for wadding. On all

three flights the rocket flew quite straight with very little roll. Here are the results of the three flights:

|

Motor

|

Altitude

|

Velocity at Deployment

|

|

A8-3

|

106 ft

|

31 ft/sec

|

|

B6-4

|

272 ft

|

21 ft/sec

|

|

C6-5

|

110 ft

|

20 ft/sec

|

Perhaps the worst flight was A8-3. The chute was quite late.

Rocksim shows the following results with AT 18mm reloads:

|

Motor

|

Altitude

|

Velocity at Deployment

|

|

D13-7

|

1206 ft

|

42 ft/sec

|

|

D21-7

|

1171 ft

|

34 ft/sec

|

|

D24-7

|

1137 ft

|

36 ft/sec

|

If built with a 24mm motor mount, Rocksim shows:

|

Motor

|

Altitude

|

Velocity at Deployment

|

|

E15W-7

|

2010 ft

|

28 ft/sec

|

|

E30T-7

|

1761 ft

|

19 ft/sec

|

|

E24W-7

|

2134 ft

|

12 ft/sec

|

Recovery:

100 lb Kevlar®

was used for a shock cord. I like to wrap tape around it where it meets the top of the body tube to help prevent

zippering. Parachute deployed just after apogee on all three flights. Rocksim shows the delays chosen as the best

match. After the three flights, the rocket still looks like new.

Summary:

I love Phoenix rockets and have built lots of them. This one was fun to design, build, and fly.

PRO's: Unlike the 2.6" diameter Phoenix from LP (or the former Estes kit), this one doesn't seem to break fins as easily.

CON's: If I build another one, I think I will try to use a 24mm motor mount. If you do this, leave

out the motor hook and block and you can also fly with an 18mm adapter.

|

|