Scratch Red Dog Original Design / Scratch Built

Scratch - Red Dog {Scratch}

Contributed by Nick Esselman

I saw a two-motor cluster in "Model Rocket Design and Construction" by Timothy S. Van Milligan that I liked the looks of and decided to build a model with that motor configuration.

The rocket uses a 24mm tube as the main body tube and two 18mm tubes for the motor mounts, one 18mm balsa nose cone and one 24mm balsa nose cone. In addition, you'll need two 18mm motor blocks.

(1) 19 1/2" - 24mm Body Tube

(1) 19 1/2" - 24mm Body Tube

(2) 4 5/8" - 18mm Body Tube

(1) 4" - 24mm Balsa Nose Cone

(1) 1 1/2" - 18mm Balsa Nose Cone

(2) - 18mm Thrust Rings

(2) - Washers

(1) - Eye Screw

1/8" Balsa Stock

Recovery Material to suit your liking

CG=12 3/4" from bottom (10 3/4" from top)

NOTE: I have just noticed that this design is a natural kit-bash of the Estes Gemini DC. The following changes should occur:

- Use (2) of the fins to make the large fins (use this pattern)

- Use the other (2) plus some the of the balsa scrap to make the (4) small fins

- The two plastic noses cones will be cut in half to start with and then sized (about 60% width removed)

- When cutting the 24mm tube, be sure to remove the two exhaust ports

- When gluing the two 18mm tubes together be sure the two exhaust ports are facing each other

- Use clay in the plastic nose cone to get the CG correct.

- My Gemini kit came with (2) motor hooks which can be used for the each of the 18mm tubes

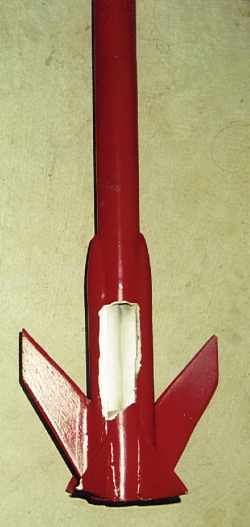

The biggest trick is cutting the main 24mm body tube to accept the two 18mm motor mounts. I glued the two motor mounts together (parallel and even) and then lined up the bottom of the 24mm tube with the tops of them until they were centered. I then marked the 24mm tube at the four points where the two motor mounts crossed it. I then took a tube marking guide and ran four straight lines up the body tube. Then using a hobby knife cut straight lines for the length of the motor mount tubes (4 5/8"). After trimming and test fitting, trimming and test fitting, there was a match. I then glued the motor mount in place by sliding it into the main body tube's grooves with glue applied on the four edges of the remaining (flaps) main body tube. I then taped it to hold it in place. After drying I applied white glue along the seam to make a better joint.

The next difficult part was to get the 18mm nose cone into two, conforming nose cones. Using a tube marking guide I marked the nose cone's base at 180° apart. Then drew a straight line from that mark to the center of the tip on both sides. I then used a hobby knife and carefully worked at cutting through the nose cone until I had two halves.

Next I taped a piece of sand paper to the main body tube then carefully and evenly sanded the back side of each nose cone half until it conformed with the main body tube and slid into the 18mm motor mount with ease. I glued both in place with white glue.

For fins, I used two forward-sweeping fins which were attached parallel onto the motor mount tubes. One on each side. I then attached the four smaller fins at the seams where the main body tube (flap) attached to the motor mount tubes and angled it to match the curve of the main body tube.

For fins, I used two forward-sweeping fins which were attached parallel onto the motor mount tubes. One on each side. I then attached the four smaller fins at the seams where the main body tube (flap) attached to the motor mount tubes and angled it to match the curve of the main body tube.

After the fins were attached I filled all the seams and applied fillets to the fins.

I used two washers, an eye-screw and some epoxy to finish the weighting of the nose cone. Pre-fit the eye-screw, pour some glue into the hole, place the washers so that they are even and surround the hole. Put a little epoxy in-between the washers and on the nose cone base and then screwed in the eye-screw. Let dry.

I used two 1/4" launch lugs. One at the very bottom of the rocket and one about 1" above center of gravity.

One last step was to take a thick glue (or you can use glue soaked tissue) and fill the gap on the sides of the motor mounts so that ejection gases wouldn't escape out the back of the rocket.

The recovery system is up to you. I attached a 3-foot piece of Kevlar to one of the motor mount thrust rings and then attached it to a 2-foot piece of 3/8" elastic and then that to the nose cone's eye-screw.

I wasn't all that concerned about finishing so I simply used several coats of primer and painted the whole rocket red. That is when I decided to start calling it Red Dog.

FLIGHT/RECOVERY:

My first flight was with two Estes C6-7's. Only one motor lit and the rocket did a large arc to about 500 feet and then started down in the same large arc. At about 50 feet the ejection charge blew out the parachute just in time to be snagged by a tree. I was able to retrieve it, however, it sustained fin damage.

My first flight was with two Estes C6-7's. Only one motor lit and the rocket did a large arc to about 500 feet and then started down in the same large arc. At about 50 feet the ejection charge blew out the parachute just in time to be snagged by a tree. I was able to retrieve it, however, it sustained fin damage.

This flight taught me two things. First, I was concerned over the stability, therefore, I lengthened the body tube by 6 inches. (The dimensions and components above are for lengthened version). The second I'll talk about in my summary.

After lengthening the body, replacing two small fins and 1 large one, and hitting it with red paint again she was ready to fly. This time on two B6-6's and using a streamer for recovery.

Both motors lit and off she went. Straight and high. Ejection was just about at apogee. Descent was very fast to me but it was recovered about 50 feet from the launch pad with no damage.

The next flight was on two Apogee's C4-7. Again, both lit and seemed to keep burning until the rocket was just a dot. I saw smoke and an ejection. The parachute certainly slowed the descent (too much) and it drifted to the far end of the launch field. Upon inspection, part of the main body tube had blown out. I believe that the Apogee motors have more of a kick at ejection and this pressurized the inside so fast that blew the side out.

The next flight was on two Apogee's C4-7. Again, both lit and seemed to keep burning until the rocket was just a dot. I saw smoke and an ejection. The parachute certainly slowed the descent (too much) and it drifted to the far end of the launch field. Upon inspection, part of the main body tube had blown out. I believe that the Apogee motors have more of a kick at ejection and this pressurized the inside so fast that blew the side out.

SUMMARY/LESSONS LEARNED:

The Red Dog is a nice rocket and I have been pleased with being able to build this from scratch and with no design except what was in my head.

The dimensions above represent the lengthened version which was needed for stability. Make sure you get the CG measurements I did without the motors in place.

If I build another, I will take a 1/4" long strip of 1/8" balsa and place it in-between the two motor mount tubes at the rear of the rocket. This will cant the motors toward the center of gravity and may prevent the large arc if only one motor lights.

Another change is to either fill the gaps between the motor tubes and the main body tube completely or at minimum make sure it is filled at the top of the motor tubes. The weakest point of the rocket is where the main body tube (flaps) attaches to the motor tubes. I don't want ejection pressure to get to this section in a future build.

If you decide to build this rocket, please send me a picture and comments.

FUTURE FLIGHTS:

After repairs (notice patch for side blow out and cracked fin) the bird has flown a number of other times. I love it on Apogee C10's, but zowwie, the get hot. Look at my melted paint!

Definately would like to build another one since I stepped on this one!

|

|