Scratch Solar Rail Original Design / Scratch Built

Scratch - Solar Rail {Scratch}

Contributed by David Hoffmeier

| Manufacturer: | Scratch |

Brief:

This is the second rocket I built to enter the EMRR Spaceship Design Contest. Having never built or flown a ring fin rocket this challenge proved to be exciting. I chose various materials for its construction including balsa wood, aircraft plywood, and dowel rods just to name a few.

Characteristics:

- Height: 27 7/8 inches Width: 4.6 inches Weight (without engine): 2.25oz

- Motor Mount: 18mm (single) Recovery: Parachute

CLICK ON ANY

PICTURE TO ENLARGE

|

||||||||||||||||||||||||||||||||||||

Construction:

The following are the major components used:

|

|

Narrative:

I broke this rocket down into three sections and tackled each one separately. I began with the tail section. I wanted to create a mock up before I started cutting the wood pieces. First I sketched a design I liked on a piece of mate board. (I get scrap pieces from the local frame shop.) Using that pattern, I cut four stanchions out of the mate board and glued them to a scrap piece BT-20 tube. I constructed both rings out of cardstock and attached them to stanchions. A roll of masking tape and a heavy cardboard tube served as my forms.

I liked the overall look of this mock up. I even created the lower paper transitions you see on the finished rocket. The only change was shorting the BT-20 tube by a half inch. Actual construction of the tail end took much longer to create than expected.

I removed one of the stanchions and used it as a template on the wood. I rough cut the wood and used double sided tape to stack the birch plywood in four layers. Following the template on top, I cut and sanded them to size. Then I glued them to the 6" BT-20, with the bottom of the stanchion even with the bottom of the tube.

I cut 1 - 5/8" and 2- 1 ¼" strips from the 1/32 Airplane plywood. Using steam on the outside I began to carefully curl the strips into smaller circles. Being very careful not to kink the wood, I placed the 5/8 strip inside the heavy cardboard tube I had used earlier. I curled the 1 ¼ strip to the inside of a tape roll. Leaving them alone, I began work on the mid section frame.

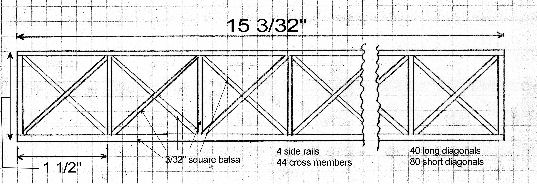

I took some graph paper and taped it to the table top and drew out the frame work. After a few sketches, I determined the outside edge of each square should measure 1 ½ inch. With 10 squares, the frame length ended up being 15 3/32". I placed a piece of clear transparency over the graph paper and began to construct the frame using the graph paper below as a guide. I constructed two sides and then began to join them using the same method.

I looked online for a solar panel design and didn’t find one I liked or that closely resembled the photo. I used the photo program on my computer and generated my solar panel design. Printed it on a color printer and cut it to size to fit inside the frame and allow a body tube to go up the middle.

I debated on using either a BT-20 or BT-50 tube through the mid section. I finally decided on a BT-50 for the inside tube. This selection will allow for the larger parachute. I had to create a square with a circle cutout to be placed in the top of the frame as to center the inside tube. The lower portion is supported by the lower assembly.

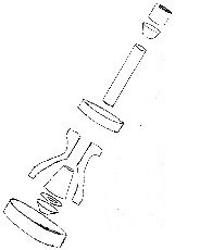

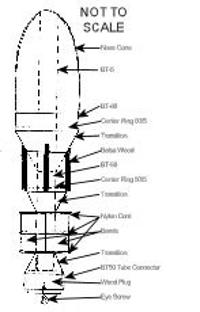

Now for the upper assembly, working from the nose down, I started with PNC-60. I cut off everything 3/8" below the shoulder. I glued a ½" section of BT-60 to the nose cone. I created a centering ring out of mate board for a BT-5 tube. I glued this ring inside the BT-60 tube. I pushed the BT-5 tube through the hole to the tip of the nose and glued it in place. I created and glued on a paper transition.

Next I took a 1" section of BT-50 with a BT-5 centering ring glued in one end and placed over the BT-5 tube and centered it over the previous transition. I created two paper ½" transitions to go from the BT-50 to the BT-5. (The same transition is used under the barrels.)

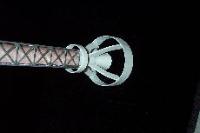

The barrels were created with four 1" pieces of 5/8 dowel rod. Once glued together, I began to drill out the center with increasing drill bit sizes. When I was close, I used a rat tail file to center the hole and allow the BT-5 tube to pass through. Though I made the transition for under the barrels I did not glue it on at this time. I glued a small nylon cord around the upper, mid, and lower sections of the barrels.

I also used a piece of dowel rod to create a plug that would fit inside a BT-5 on one end and a BT-50 on the other.

Painting of the rocket was done in sections. Final assembly occurred after paint.

- The barrels had the added detail of small nylon cord around them in three places. Once in place the barrels were painted tan, and later trimmed with dark brown.

- The frame was painted metallic silver.

- The remaining rocket was painted gloss white.

- The silver and black accents were added later.

Once the paint was dried, I assembled the upper section first. I attached the barrels with a little wood glue and added the lower transition. I hand drilled a small pilot hole in the wood plug for the eye screw. I glued a BT-50 coupling ring to the plug, and then I attached the plug to the BT-5 tube.

Before attaching the mid section to the lower assembly I inserted the paper solar panels inside the frame. I scraped off the paint where the lower assembly and frame would meet. I glued the frame at the four points on the lower assembly and around the tube at the top. I wanted to make a better fit and a stronger connection at the top, so I attached a center ring (which I first painted silver).

It was at this point I realized I didn’t have a launch lug. Once I figured out where I wanted it, I painted it to match and attached it with white glue.

I wanted to test this in some rocket software but wasn’t sure how to put in a square body with all the other detail of this rocket. I tried to do a swing test and could not get the rocket to fly straight. Using RockSim I created the rocket as though it had large smooth body tubes.

In my design, RockSim said I had an over stable rocket of 3 something. To counter this I created forward fins ¾" tall and 1 ½" in length. This modification brought my stability to 1.8. To keep with the ring fin design of the rocket I added a ½" paper ring to the fin tips. This brought my stability down to 1.1.

I created this new ring fin to attach to the rocket but not permanently. I still wanted to keep the original look of rocket like the photo. These fins are only attached for flight (like the Saturn IV rocket, ha-ha). They were made using a ¾" BT-55 tube, balsa, centering rings, and ½" cardstock paper ring.

This fin slides on the body tube just above the frame. I conducted the swing test again with this fin on and it flies straight, backwards. Uggghhh. I’m just going to launch it and see what happens.

| Date |

Motor |

Ejection / Altitude |

Wind |

Notes |

| 10/26/06 |

C6-3 |

Just before / 150 |

12 |

No damage |

| 10/30/06 |

C6-3 |

Just before / 140 |

17 |

Landed on roof, scuffs, no damage |

| 10/30/06 |

C6-3 |

Just before / 140 |

17 |

No damage |

I haven’t launched the Solar Rail with the forward ring attached. I wanted to get three launches in without the ring. I’ll add the ring for a fourth launch when these winds die down. This rocket has taken some hard hit and survived. I may build a larger 24mm version, after I see how others built theirs. Maybe I’ll be able to pick up some ideas I hadn’t thought of and that wouldn’t be to hard.

This was an awesome contest. I hope you do it again in the future. Good luck to everyone!

FLIGHT #1

FLIGHT #2

FLIGHT #3

|

|