Scratch Thunderscreech Original Design / Scratch Built

Scratch - Thunderscreech {Scratch}

Contributed by Joseph Pscolka Jr

| Manufacturer: | Scratch |

Brief:

Ever since my cousin purchased his Estes Screamin' Mimi, I've toyed with the

idea of doing an upscale version. I've grown tired of building 3FNC and 4FNC

rockets, so I decided a high power upscale of this unique rocket would be a

nice challenge. Also since I have a lot of spare parts like BT-3.0 body tube

cutoffs, BT-55 cutoffs, scraps of fiberglass, etc., I could use up a bunch of

them and make a little much needed room in my shop.

Construction:

The parts list:

- 1 LOC PNC-3.0

- 1 LOC BT-3.0 tube, 7" long

- 2 LOC BT-3.0 tubes, 16" long

- 2 LOC TC-3.0 tube couplers

- 1 1/4" plywood bulkhead

- 1 3/16" U-bolt

- 1/8" aircraft plywood for all 8 fins

- 1/4" aircraft plywood for 3 centering rings

- 13" PML PT-1.5

- 38mm Slimline motor retainer

- 15' of 1/2" flat Kevlar® recovery harness

- 30" of 1" nylon strap

- 4' of 550# (parachute) cord

- PML 24" parachute for drogue

- TAC-1 48" main parachute

- Tether by Devy Gravity

- Kevlar® heat shield for drogue

- 10" x 10" Nomex® heat shield for main chute

- 3 1/8" quick links

- 4 7½" BT-55 tubes

- 4 6¼" BT-5 tubes

- 2" x 2" x 12" basswood turning stock

- 4 24kt gold plated whistles

- terminal blocks

- rail buttons

- 6 oz satin weave fiberglass

System Three 5 minute epoxy resin was used for initial tacking of fins and other parts in place. West Systems epoxy resin and 206 hardener were used for fiberglass laminations. West Systems was mixed with colloidal silica for all structural fillets.

Because I had a half dozen BT-3.0 cutoffs laying around I decided to do a 2x upscale. So I joined two 16" long body tubes to make the main airframe, and picked out a 7" long piece for the electronics bay. After calculating the size of the fins and the through-the-wall tabs, I proceeded to lay out and cut the 8 tab slots with a scalpel and a 24" length of aluminum angle.

Next, I found enough 6oz satin weave fiberglass to give the tubes several wraps. Using my homemade rotisserie stand, I laid up the tubes, set them aside to cure, then began making templates for the aft fins and the whistle-tube standoffs. Once all 8 fins were cut out with leading and trailing edges beveled I proceeded to glass them one side at a time with a single layer of 6oz glass as well.

On to the motor mount...I made three centering rings from the ¼" aircraft plywood, and cut the PT-1.5 to 13" in length. I epoxied the top centering ring and 4" of a 30" length of 1" nylon strap to the top of the motor mount. Then the middle centering ring was epoxied at the point where the top of the whistle-tube fin tab would rest on the motor mount tube. The aft centering ring was left off so internal reinforcement could be accomplished.

After the body tubes cured and all 8 fins were covered with glass, I removed the fiberglass from the fin slots for the whistle-tube standoffs, then epoxied the motor mount in place, followed by tacking the whistle-tube standoffs to the motor mount. The standoffs received fillets at the fin to body tube joint using West Systems epoxy mixed with colloidal silica. The fin tabs were secured to the motor mount and inside of the body tube using 6oz glass.

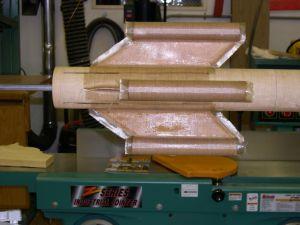

Now things got a little tricky with designing the whistle-tubes.

It took me quite some time to find just the right type of whistle to use. They

were right under my nose all the time. I use a wood lathe to turn all manner of

pen and pencil sets, letter openers, key chain fobs, etc. with wooden barrels.

One of the key chain fobs just happens to have an extremely loud security

whistle that's part of it. It also happens to be 24kt gold plated! I made

centering rings to hold and secure the whistles into the ends of the tubes.

When I blew into the end of the BT-55, the sound was pathetic. Eventually I

figured out that restricting the airflow to the whistle using a BT-5 solved

that problem. Next I turned forcing cones out of basswood for the foreword ends

of the whistle tubes, with a 4 degree outside taper and a 9 degree taper on the

inside acting sort of like a Ram Jet. The photo illustrates what it all looks

like before assembly. The cone, air tube, centering ring, and whistle were

epoxied in the BT-55 tubes after all the glassing was accomplished.

Now things got a little tricky with designing the whistle-tubes.

It took me quite some time to find just the right type of whistle to use. They

were right under my nose all the time. I use a wood lathe to turn all manner of

pen and pencil sets, letter openers, key chain fobs, etc. with wooden barrels.

One of the key chain fobs just happens to have an extremely loud security

whistle that's part of it. It also happens to be 24kt gold plated! I made

centering rings to hold and secure the whistles into the ends of the tubes.

When I blew into the end of the BT-55, the sound was pathetic. Eventually I

figured out that restricting the airflow to the whistle using a BT-5 solved

that problem. Next I turned forcing cones out of basswood for the foreword ends

of the whistle tubes, with a 4 degree outside taper and a 9 degree taper on the

inside acting sort of like a Ram Jet. The photo illustrates what it all looks

like before assembly. The cone, air tube, centering ring, and whistle were

epoxied in the BT-55 tubes after all the glassing was accomplished.

Since I was using flimsy BT-55 tubes, I decided that they needed to be glassed to the standoffs. After cutting the BT-55 tubes to length, I tacked them to the standoffs. I made a jig that clamped onto the standoff to hold the tubes perfectly centered. Later, I added fillets to the BT-55 to standoff joints using West Systems epoxy resin mixed with colloidal silica.

Next I cut four pieces of 6oz glass to be laid up on the body

tube between the whistle-tube standoffs, up the standoffs, over the BT-55

tubes, down the other side of the standoffs, ending on the body tube between

the standoffs. Mounting the body tube on my handy-dandy rotisserie all four

standoff/whistle-tubes were glassed at the same time, overlapping the glass on

the body tube between the fins. Since I didn't vacuum bag this thing (I'm not

sure it can even be done), I spent nearly an hour frantically squeegeeing out

about a billion air bubbles that appeared as if by magic. After the glass had

cured for several days, I sanded down and feathered all the seams. This was

important to do because the aft fins would also receive fin-tip to fin-tip

glass lay-ups that would create more ridges. There were only a half dozen small

bubbles in the glass that were filled later.

Next I cut four pieces of 6oz glass to be laid up on the body

tube between the whistle-tube standoffs, up the standoffs, over the BT-55

tubes, down the other side of the standoffs, ending on the body tube between

the standoffs. Mounting the body tube on my handy-dandy rotisserie all four

standoff/whistle-tubes were glassed at the same time, overlapping the glass on

the body tube between the fins. Since I didn't vacuum bag this thing (I'm not

sure it can even be done), I spent nearly an hour frantically squeegeeing out

about a billion air bubbles that appeared as if by magic. After the glass had

cured for several days, I sanded down and feathered all the seams. This was

important to do because the aft fins would also receive fin-tip to fin-tip

glass lay-ups that would create more ridges. There were only a half dozen small

bubbles in the glass that were filled later.

Then the aft fins were tacked to the motor mount and filleted at the fin-tube joint. Later the tabs were secured on the inside of the tube in the same manner as the standoffs. Next the aft centering ring was epoxied in place followed by the 38mm Slimline motor retainer using JB Weld.

Now that the tubes have been glassed and all the fins attached and glassed to the tube, it's was time to begin sanding. A lot of sanding! If you've never tried the new Norton 3X sandpaper, I highly recommend it. The 100 grit cuts faster than standard 80 grit but leaves a finer scratch pattern. The same goes for the 150 grit and finer. This sandpaper works as advertised ("cuts three times faster and lasts three times longer") with very little clogging or corning as compared to standard sandpaper. At this point there were a number of imperfections that required filling. I use an aerospace grade body filler that I don't think is available outside of the aerospace industry. Sanding, filling, sanding, filling, sanding, sanding, sanding, sanding...

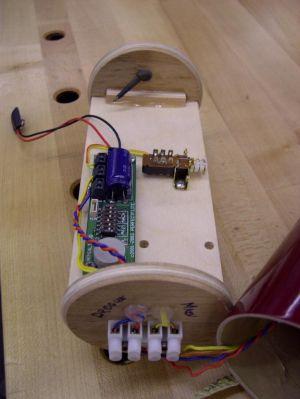

The electronics bay came next and consists of a 7" long

glassed BT-3.0, a 6" long coupler, 1/4" plywood coupler bulkhead,

3/16" U-bolt, and terminal blocks for ejection charges. Lastly, the

electronics sled consists of two 1/4" plywood bulkheads, one sized to fit

the coupler the other the BT-3.0, and a 2.75" x 6" piece of 1/8"

plywood for mounting electronics. The 1/8" plywood is attached to the

bulkheads with glue blocks epoxied to each side. There are also terminal blocks

for wiring between sled and e-bay coupler bulkhead.

The electronics bay came next and consists of a 7" long

glassed BT-3.0, a 6" long coupler, 1/4" plywood coupler bulkhead,

3/16" U-bolt, and terminal blocks for ejection charges. Lastly, the

electronics sled consists of two 1/4" plywood bulkheads, one sized to fit

the coupler the other the BT-3.0, and a 2.75" x 6" piece of 1/8"

plywood for mounting electronics. The 1/8" plywood is attached to the

bulkheads with glue blocks epoxied to each side. There are also terminal blocks

for wiring between sled and e-bay coupler bulkhead.

Finishing:

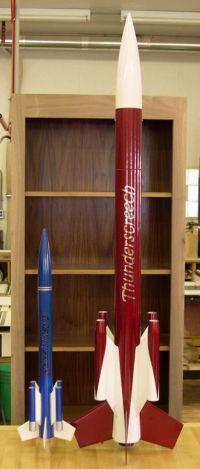

I know all this sounds like I'm knocking this stuff out one right after

another, but in reality it took me just over four months to complete this

project. I own and operate a woodworking business. Business must come first, so

I only get to work on this stuff an hour here and an hour there. That being the

case, my cousin Aaron did all the painting. After several coats of automotive

primer were applied and wet sanded, a combination of white and deep burgundy

automotive paints were applied and buffed out. Lastly, a custom made chrome

"Thunderscreech" decal was applied.

Flight:

The first flight of Thunderscreech was at Tripoli Pittsburgh Dragon's Fire 35

in August 2004. I've always said I'd never fly an unfinished rocket, but I

couldn't wait to see if the gold plated whistles were going to sound good.

Since I was still waiting for the Tether Pyro-Release mechanism to arrive, I

decided to fly the Thunderscreech using motor deployment of the main only. I

also used a SkyAngle 36 for this flight because without being rigged for

dual-deployment, it only weighed 64oz. Since I wanted this rocket to attain a

high air speed, I searched high and low for an I357T but had to settle for an

I218R.

I prepped the rocket, loaded it on the rail, and waited my turn. Francis Graham counted down and pushed the button. Wham. That Redline motor ignited instantly accompanied by the very loud high pitched screamin' of the whistles. It was great. The medium delay was perfect, the rocket did a tail stand and ejected the SkyAngle parachute. The SkyAngle 36 was a bit small thus the rocket fell like a rock but was undamaged upon landing.

Thunderscreech has flown eight more times--5 of flights on

I300Ts, one I435T, one J350W, and one J570W. All of these flights were under

dual-deployment using a 24" drogue and the TAC-1 48" main

parachute--a perfect combination. The J350W is the perfect motor for this

rocket because it attains very high velocity right off the pad and burns out

quickly so you can hear the incredible screaming of the four whistles. It also

just fits. The J570W on the other hand has to be friction fitted in order to

leave enough room for the drogue and main parachutes. The case must protrude

from the motor mount about four inches. But man that rocket rips off the pad

like a bolt of lightning to an altimeter reading of 4452'. The screeching of

the whistles was so loud that it caused momentary pain in the ears of

rocketeers standing near the LCO station.

Thunderscreech has flown eight more times--5 of flights on

I300Ts, one I435T, one J350W, and one J570W. All of these flights were under

dual-deployment using a 24" drogue and the TAC-1 48" main

parachute--a perfect combination. The J350W is the perfect motor for this

rocket because it attains very high velocity right off the pad and burns out

quickly so you can hear the incredible screaming of the four whistles. It also

just fits. The J570W on the other hand has to be friction fitted in order to

leave enough room for the drogue and main parachutes. The case must protrude

from the motor mount about four inches. But man that rocket rips off the pad

like a bolt of lightning to an altimeter reading of 4452'. The screeching of

the whistles was so loud that it caused momentary pain in the ears of

rocketeers standing near the LCO station.

Summary:

This model was a welcome diversion from building 3FNC models. I was concerned

about stability but my calculation seem to have been right on the mark. The

Thunderscreech flys perfectly. If you check out the RockSim file you'll notice

a CD Adjustment object at the bottom of the components list. This is my down

and dirty solution for correcting RockSim's inability to calculate the drag of

the whistle tube standoffs as well as the whistle tubes. Without this object,

the reported altitude for a given motor will be about 30% too high.

Everyone keeps hounding me to build an even bigger one. Who knows, maybe something that can handle an N4800T!?

|

|