Scratch TOGinator Original Design / Scratch Built

Scratch - TOGinator {Scratch}

Contributed by Boris Katan

| Manufacturer: | Scratch |

Brief:

Late 2006 I bought and built a FlisKits US TOG. Futuristic and very cool looking, it flies on D12-5 engines very nicely to somewhere around 500ft. I knew that I had to build an upscale one day.

Now that it is winter in New England, it's rocket building season. The 1, 1.3, and 1.6 inch tubes used in the original, when multiplied by 1.6 come very close to LOC 1.6, 2.2, and 2.6 inch tubing so that's what I went for. I took careful measurements and tracings on my original US TOG then scanned and reprinted them 1.6x larger.

If, however one was to consider this an upscale of the FlisKits MicroMax TOG, then this would be an amazing 5.6x upscale! The sheer size of this project is mind boggling!

Original plan was to build something that would get a decent flight on a G64. All parts are 1.6x, except I stretched the two central body tubes a little longer, both to make the rocket bigger and also more stable. I also made the chord 1/2 inch longer than scale for the inner fins. The TOG has a lot of fin area, but this upscale with plywood and fiberglass fins has a relatively heavy fin structure. Nosecone and transition are balsa and were turned by Mike at Cosmodrome Rocketry. (I will build one of their beautiful Lambda kits when they start production.)

Construction:

I put two layers of 2oz glass on the 2.6 inch tube as it was not as thick as the 1.6 and 2.2 LOC tubes. Outer fin tips are 1/8 plywood. Inner fin sections are two layers of 1/8 plywood epoxied together for greater stiffness.

The TOG's fins are not only large, but they have outboard tubes and a lot of angle to them. While the US TOG flies great on a D, Jim Flis was very clear that it bad things would happen with an E engine.

I will do tip-to-tip fiberglass over the whole fin structure and epoxying inner fins TTW. The marked tube is exactly on the opposite side from fin and lined up with right angle ruler to align fin.

Jim Flis commented that the ram jets' tiny internal fin structures needed strength support added to them. I must confess I didn't put them in my US TOG. I had assumed that they were only decorative and didn't like the way the paint I had used made them look. I wonder if open tubes that are 3-5 times longer than their diameter operate as fins. Do they have enough internal air flow? The ram jet tubes cut to shape from pretty thick 54mm and 38mm LOC tubes. I peeled off the glassine so tip to tip fiberglass will soak into tubes. I planned on using enough fiberglass to cover all fin structures including all three ramjet tubes.

Each fin span is about 10 inches. My FlisKits US TOG is 35 inches tall and 4.5oz. A 1.6x upscale should be 56 inches tall, but I made the two central body tubes longer because I liked the way it looks. It's also more stable, but with that much fin area, I doubt this is an issue. I thought two things as I looked at it:

- Wow, that FlisKits TOG is a beautiful rocket, and it looks even better supersized.

- Wow, I have to do 30 fin fillets now.

I applied fillets using Locktite 5-minute epoxy, Popsicle sticks, and tape. I read about the tape idea on TRF, which keeps the fillet edges clean and uniform. This was my first time using it, and it works great. I will always do this going forward. I used some scraps of Kevlar thread as a sort of caulk to keep epoxy from flowing through the TTW joints during assembly.

I applied fillets using Locktite 5-minute epoxy, Popsicle sticks, and tape. I read about the tape idea on TRF, which keeps the fillet edges clean and uniform. This was my first time using it, and it works great. I will always do this going forward. I used some scraps of Kevlar thread as a sort of caulk to keep epoxy from flowing through the TTW joints during assembly.

I got the 30 fin fillets done. The two matching "bottom" fins seemed to be stiffer than the single "top" fin that angles forward so I decided to use more fiberglass on the top one. I was concerned about shredding off the fins so I am using plenty of fiberglass.

I had originally hoped to build the rocket ready to fly at about 2 pounds, which would give me a pretty good flight on a G64. In the planning stage, I weighed the tubing and got 15oz. The 1/8 and 1/4 plywood fins and balsa transition and NC added another 10oz. Now fiberglass and many fillets are adding another 10oz. I figure about another 9oz for recovery and a G engine puts the rocket ready to fly at 2.8lbs. A G will loft it, but not very high, maybe 500-700ft.

The good news is that the fins are turning out very stiff with all that fiberglass on them. The 38mm engine mount would happily receive an H or even an I with moderate thrust. Another possibility would be to add a couple 29mm engine tubes and fly F and G clusters of 2 to 3 engines.

Due to the growing weight of this project, I decided to add a couple more engine tubes. The two new engine tubes are 29mm tubes canted towards best estimate of ready to fly CG. The separate engine flames should be very cool... I'm picturing a central Redline with a White Lightning on each side. This lower section now weighs the 2lbs that was my original target weight for the whole rocket. Engine tubes now covered with 4oz fiberglass, side fins with 7oz, and top fin with 13oz each side. With a central 38mm engine tube and a 29mm on each side, it can now fly on 2 or 3 Gs or a central 38mm H or I. I don't anticipate going much past I total impulse to avoid losing fins. As well, I decided to build in dual deployment both for safety with a canted AP cluster and to recover in a smaller landing area. I used 4 inches of coupler (internally reinforced with another coupler) at the top and bottom of the ebay to maximize stiffness at separation points. This project keeps getting bigger and more complex. In addition to the central 38mm engine tube and the two 29mm canted outboards, I have added 23 short 24mm tubes. The smaller tubes can serve as mini tube fins, or some or all of them can be loaded with 24mm engines. I replaced the 38mm to 54mm balsa transition as a 38mm separation point would not be strong enough. I went with longer 24mm tubes for the one row that supports a second row of tubes for stiffness and strength. All tubes shown here are LOC tubing covered by 4oz of fiberglass. Every small tube has 2+ points of attachment by epoxy and is very rigid.

An Estes D engine is taped at both ends to retain it in the tube. A few or many engines can be installed in this way, as long as thrust symmetry and adequate thrust are maintained. As I have not seen a flexible tube fin / engine mount with both ends of the engine exposed like this before, I am naming it: The Engine Bikini--it's just enough to do the job, leaving very little to the imagination, likely to be controversial, shocking and exciting all at the same time. Naturally I was concerned about maintaining a balance of thrust about the centerline of the rocket.

An Estes D engine is taped at both ends to retain it in the tube. A few or many engines can be installed in this way, as long as thrust symmetry and adequate thrust are maintained. As I have not seen a flexible tube fin / engine mount with both ends of the engine exposed like this before, I am naming it: The Engine Bikini--it's just enough to do the job, leaving very little to the imagination, likely to be controversial, shocking and exciting all at the same time. Naturally I was concerned about maintaining a balance of thrust about the centerline of the rocket.

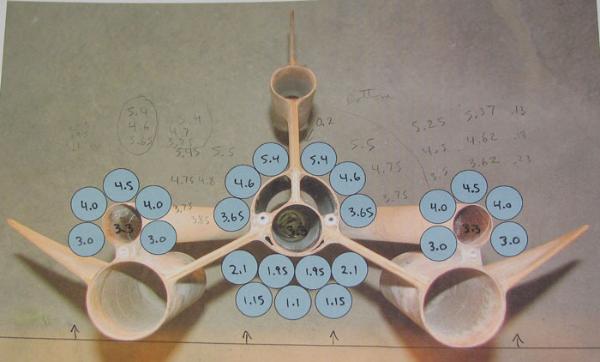

Before adding the 24mm tubes, I took a picture of the rocket and used PowerPoint to superimpose drawn circles representing the 24mm tubes. This allowed me to try many different possibilities. Design requirement was thrust balance and 20+ total engine capacity. After settling on a design that appeared to balance on paper, I installed the first 17 tubes: the sets of 5 tubes on each side and the set of seven on the bottom. Then I measured the height in inches from the table top (reference position shown as the line at the bottom of the picture) to the centerline of each engine tube. Those are the numbers written in marker. This allowed me to fine tune the exact positioning of the six tubes nearest the upright center fin to achieve balanced thrust, in the top to bottom dimension. That fine tuning is the pencil notes. There are a total of 26 potential engine tubes in this rocket. One 38mm, two 29mm, and twenty-three 24mm.

As the project got heavier, I had to lengthen the parachute compartment to hold a larger (48") chute. The TOGinator is now 82" tall and will weigh about 4.8 lbs flight ready minus engines.

First flight will be at the 4/19/08 CMASS launch in Amesbury, MA. Will load 26x D11-P engines for the first flight. 468 Ns impulse, I power on BP. If "flight is nominal" expect to get 1000+ft altitude. Dual deployment will help with recovery and is also insurance in case flight is not to plan. (NOTE: In 2007 I lit all 70 BP engines attempted in 12 BP cluster launches using igniters from Rocketflite. I plan on using their very good products this year as well.) I test loaded the maximum number of engines and then assembled the rest of the rocket as if ready to fly.

First checked CG on my FlisKits US TOG - the kit that inspired this project - and got:

- Overall length: 34.5" (had removed 1/2" of lower tube due to crimp)

- Weight ready to fly (with one D12-5): 5.55oz

- CG: 25.25"

CG is 73% of overall length and this rocket flies very straight. So I will target the same percentage point for CG on the larger TOGinator. With the extra structures and drag the TOGinator has at the back of the rocket, stability should be assured.

The TOGinator specs ready to fly with 26x D11-P engines:

- Overall length: 82.5"

- Weight with engines: 125oz (Weight without engines: 76oz)

I had to add 6oz nose weight to put CG at 73% of overall length: 60.0". This is how I plan to setup the first flight.

Finishing:

Sand, prime, Bondo, sand, prime, Bondo, sand...however, I had not used Bondo Spot Putty as a filler before. It is nasty to apply, melted the Kilz primer if I attempted to work it too much, ate through my nitrile gloves after a few minutes, and smelled as bad as CA. Pluses were that I could fill after priming if I applied the Bondo very quickly and it sanded very nicely.

I brush painted the insides of the tubes red--the "ramjets" with two coats of medium thickness acrylic.

I brush painted the insides of the tubes red--the "ramjets" with two coats of medium thickness acrylic.

Flight and Recovery:

Flight day at last! CMASS launch at Amesbury, MA. It was a beautiful day with moderate winds. A great day to start our flying season.

Setting up, thanks to Bob K and Tony V for assistance at the pad. Slightly angled into the moderate wind. This series and parallel arrangement greatly reduced current load on the launch system, drawing about 50A. If a conventional setup of 26 one ohm igniters were used in parallel the power draw would have been over 300A.

The flight lifted off on a nice straight path with a wide fan of flame visible to most of the crowd. Lift off was perfect. All 26 engines lit with a lot of smoke, fire, and noise. The altimeter reported an altitude of 765ft, which was a little less than I expected but it kept the liftoff slow enough to watch and enjoy. I got so excited at this launch that I did not track it well as I took video. So this video is short and slowed down 8x so you can see the liftoff.

The drogue ejected, but half the lines were burned through by the ejection charge. The main chute jammed and did not deploy at all. I had a hard time packing a 4ft chute, 25ft nylon harness and Nomex heat shield into the 54mm body.

The 8lb rocket came in fast under a partial 24" drogue and there was moderate damage. The narrow 38mm center of the rocket broke, and there was a crack in the epoxy where one side engine cluster joins an outboard tube fin. Considering it came in with a solid thud and I had to use both hands to pull the NC out of the ground, it held up well.

Repairing the TOGinator is no problem. My concern is how to better manage recovery in the future. I will replace the long, thin, main body tube with one of a larger diameter. The TOGinator will be back later this season...

Thanks to Jim Flis for his picture and the many cool FlisKits rockets that inspired this design. I have this pic as the desktop on 2 of my PCs and a couple FlisKits waiting to be built. Thanks to Greg Dyben at Rocketflite for producing some awesome ematches and igniters.

|

|