| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Diameter: | 1.04 inches |

| Length: | 23.00 inches |

| Manufacturer: | Semroc  |

| Skill Level: | 2 |

| Style: | Multi-Stage, Scale |

Brief:

Semroc has developed (or continues to develop) a line of kits called "Retro Repro". These kits are

reproductions of out-of-production models that had some level of significance in the model rocket industry. The kits

are generally true to the original except for utilizing modern techniques as well as materials.

The Arcon-Hi was a kit first developed by Centuri in the mid-1960s. It was a semi-scale model of the Arcon sounding rocket. Centuri converted it to a 2-stage kit using a double-coupler method that was later patented. The sustainer was a 1/6th scale model of the sounding rocket, but the booster was not to scale as it wasn't original to the sounding rocket.

Semroc describes this kit as a Skill Level 2 and that seems about right. There are many components, a unique coupling method, some techniques that require the builder to pay attention (no real "gotchas" but does require planning), and precision during building is necessary.

This rocket is perfect for the Skill Level 1 builder looking for a challenge or a step up to Level 2.

Construction:

The components for this kit came well packaged. I had just completed a Semroc SLS Jaguar so I did note some

differences between the two kits. However, the Jaguar is considered a mid-power rocket and came from a higher end line

of kits so the comparison may not be appropriate. Even so, the Arcon-Hi components appeared sturdy and of relatively

good quality.

As seen in the picture, the components in the kit include:

- 5 body tubes (2 engine tubes, a booster, sustainer, and payload)

- 3 couplers (including 1 balsa one)

- 4 centering rings

- 2 thrust blocks

- 4 booster and 4 sustainer fins

- empty engine casing for measuring/spacing (nice touch!)

- nose cone

- parachute and recovery system (Kevlar® thread, elastic, screw eye, parachute that requires assembly)

All parts were accounted for. Semroc's attention to detail continues to be evident. This company makes kits I will enjoy making.

The end of the sustainer was a little bent and creased, and I have little doubt Semroc would have replaced it if I asked. After several dry fits of the balsa coupler, I was able to smooth out the crease.

The balsa parts seemed to be of decent quality. The fins felt a little thicker than other kits and were flexible but not flimsy. The nosecone had an even grain that was easy to fill. It didn't require any extra sanding to make symmetrical.

The instructions are detailed, nicely laid out, and easy to follow. There are several steps that have the related picture on the next page, requiring the builder to flip back and forth, a minor inconvenience. The instructions have an "exploded view", which I did find to be helpful several times as I wasn't used to a kit with so many components.

Just like the SLS Jaguar kit, the font is easier to follow than kits from other companies. I usually have the instructions off to the side and it was nice not having to lean over so far to refer to them. The illustrations were nicely drawn and easy to follow.

During a dry-fit, I noticed many of the components fit loosely. The nosecone in required tape to make a snug fit. The centering rings and thrust blocks also felt too easy to slide on (I'm used to having to sand these). The couplers were very snug and they all required some sanding.

Assembly follows a logical progression: engine tubes/mounts first, booster stage then sustainer, followed by the fins and recovery system. I followed the directions in order except for a few steps, which are described below. I did do a mod at the very end, which is discussed below too.

All assembly was done with Titebond III, but fin fillets were made using JB Weld. I usually use Loctite 5 minute epoxy. I read a lot about JB Weld so thought I'd try it. It's a little easier to use and definitely easier to make nicer fillets around smaller fins.

One area that required attention was both engine mounts are not built identically. During the booster assembly, there is an instruction or two that states "repeat with the 2nd engine mount". I went too far and repeated too many of the steps and had to remove a centering ring before the glue set. While this was my fault and doesn't count as a "gotcha", I do feel the instructions should minimize the "back and forth" and keep the assembly of the booster separate from the assembly of the sustainer.

Before attaching the fins I did another dry fit, and I would recommend this to other builders. The couplers required some sanding, and I imagine this is easier to do prior to the fins being attached. This step is not listed in the instructions.

The photo shows the dual coupling method that Centuri had patented. The engine mount of the sustainer slides inside the inner coupler of the booster. It is this connection that required sanding. The reader may note the inner coupler has 2 vent holes to help facilitate ignition of the sustainer engine--it is my guess that they let cool air escape, allowing hot gases to enter the sustainer engine. Otherwise the cool air might block the hot gases and contribute to pressurizing the connection and ejecting the booster.

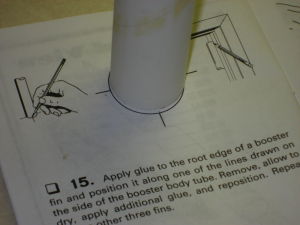

The only "gotcha" in the kit involved the steps for attaching and aligning the fins. Instead of

cutting out a section of paper with marks and taping it to the body tube, there is a circle drawn on the page with

marks around the edge. The builder is to stand the rocket on the circle and mark the tube where the fins are to be

attached. As seen in the picture, the circle was a larger diameter than the body tube, making transferring marks evenly

a challenge.

The only "gotcha" in the kit involved the steps for attaching and aligning the fins. Instead of

cutting out a section of paper with marks and taping it to the body tube, there is a circle drawn on the page with

marks around the edge. The builder is to stand the rocket on the circle and mark the tube where the fins are to be

attached. As seen in the picture, the circle was a larger diameter than the body tube, making transferring marks evenly

a challenge.

The directions have the builder transfer marks to the booster and sustainer in separate sequences. To prevent mis-alignment, I made the marks on the booster, attached the sustainer to the booster, and drew lines on both tubes at the same time. Even with my technique, I still have a slight spacing error as indicated by the fins lining up only in a certain way. That is, the first line I drew on the booster has to be in line with the corresponding line on the sustainer, etc. To ease alignment during flight preparation (as the lines will be covered by paint), I drew marks on the couplers.

If I were to assemble this kit again, one thing I would do differently is glue the fins on the sustainer

first. I would then connect the two stages and glue the fins on the booster, making sure they are in line with the fins

on the sustainer. The root edges of my fins all lined up, but as seen in the picture, there is a fin that leans a

little to the side (this actually happened to 2 fins) and therefore are out of alignment.

If I were to assemble this kit again, one thing I would do differently is glue the fins on the sustainer

first. I would then connect the two stages and glue the fins on the booster, making sure they are in line with the fins

on the sustainer. The root edges of my fins all lined up, but as seen in the picture, there is a fin that leans a

little to the side (this actually happened to 2 fins) and therefore are out of alignment.

Another thing I would do differently is build in some form of adjunctive engine retention for the sustainer so I won't have to rely solely on a friction fit. There is no room at the base of the fins for tape, and the engine fit is fairly snug already.

Here is a modification I performed: After I built the rocket, I epoxied some 60# Kevlar® thread across the engine mount. This will slide over the engine and help hold it in place during ejection. To allow the booster to slide on, I cut out rectangular sections that align with the epoxy placements. This of course would be easier to do prior to building the rocket. I did not use an engine clip because there wasn't enough room to allow epoxy to hold the clip and a small distance to allow the clip to be raised.

Assembling the payload is straightforward and didn't require any special instructions or techniques.

Finishing:

As of this writing, I have only primed the rocket. Instead I focused on completing assembly, and launching off a

maiden flight.

I usually paint my kits differently than on the picture on the kit. My 4 1/2 yr-old son likes to help choose the colors. However, because this is a first review for this rocket, I will try to follow the color scheme of black, yellow, and silver and send a picture later. I will use a metallic silver (or the shiny side of aluminum foil on 1 or 2 fins) to help it be easier to find in the air and on the ground. Because I'm not used to following schemes, I anticipate a slight challenge.

Semroc states the finish weight is 1.9oz. With the primer, mine weighed in at nearly 3oz. This is likely due to the extra epoxy for the fillets. I'm a little concerned about stability, because I intend on using a beeper/locating device when I launch it.

I'm rating assembly a 4 because I didn't like the fin alignment method. I prefer to have a cut-out strip to tape to the body. Also, I think my technique of attaching the two stages before drawing the lines shouldn't be considered an epiphany and should be part of the instructions.

Construction Rating: 4 out of 5

Flight:

I finished this rocket about two weeks before I had a chance to launch it. The waiting, as the saying goes, is the

hardest part. I took my launch stuff to work once or twice in case I had the opportunity with low wind and decent

weather. Finally, a lunch launch came to be...

Preparation was fairly straightforward. I initially put a single layer of masking tape around the middle of the sustainer engine, then a double layer at the aft end. I had a lot of trouble getting the engine in, I nearly bent the body tube. It did compress a little along a spiral and one of the fins became slightly deformed from my thumb. I really need to perfect my friction fit technique. I took off the double layer, put in the engine, and taped the Kevlar® thread in place. Without the Kevlar® as the engine definitely would not have stayed in.

The booster was easy to prepare. I used 3 pieces of wadding, put in the chute, and attached my Transolve micro trans beep. Everything fit easily. I had to use tape around the base of the nosecone.

I used a C6-0 for the booster because the store didn't have any B6-0 engines. This is just as good because the rocket was heavier than intended due to the extra fillets and the trans beeper. The beeper alone is nearly 0.5oz so my rocket is 1.5 times the predetermined weight.

I didn't have a large field so I wanted to use a B engine for the sustainer. Although a B6-6 is recommended, all I had was a B6-4 so used that.

The flight was beautiful. I'm 40 years old and still get giddy when I launch a rocket, particularly a maiden launch. I'm guessing it was due to the added weight, but this thing launched much like my Quest Superbird: slow, big puff of smoke, almost a little wobbly at first (I use a 4' launch rod, good thing too)... It was really fun to watch.

The booster took it up to maybe 150 feet or so. Then it ejected and the sustainer took off like afterburners were kicked into overdrive. It was a really fun, awesome flight to watch.

It went nearly out of sight. I'm not sure what RockSim would have predicted, but I'm guessing nearly 1000' even with the added weight. The chute came out perfectly and I looked down to get the booster, which landed about 20' away. When I looked up I had difficulty finding the rocket. I'm really glad I used the beeper, because I found my rocket on someone's roof. It being midday, the family was out to work/school, etc. It was approaching 100 deg and really high humidity and I didn't want to tempt fate with the police, so instead of climbing up to retrieve it, I left a note and will go back later to retrieve it.

Recovery:

I did have difficulties with the parachute. It's a nice plastic but thick and durable chute. The shrouds do not go

through the chute but are threaded through circle stickies (similar to hole reinforcements but without the hole in the

middle) and stuck to the chute. The problem is when I threaded the shrouds through the sticky, it lost adhesion. I

tried gluing them but they still didn't stick. I used 5 min epoxy with some success. I ended up covering each circle

with some clear packing tape.

After the launch, the chute deployed just fine. I do feel descent was too fast, but this is likely due to the added weight not due to the chute being too small.

Though my rocket is still on the rooftop, I was able to see it pretty clearly and there is no evidence of damage.

I'm rating flight recovery a 4.5 only because I felt the shrouds could be better connected to the chute.

Flight Rating: 4 out of 5

Summary:

This rocket is perfect for the Skill Level 1 builder looking for a challenge and ready to enter Level 2 models. It is

a fun rocket to build and fly but does require a level of attention that is atypical of most skill level 1 kits.

Overall Rating: 4 out of 5

|

|

Flights

|

|

|

|

J.W.P. (August 2, 2008)