| Manufacturer: | Semroc  |

Brief:

This is a baffle for a BT-55 rocket. I purchased it from the model rocket shop for £1. After building it, I went

back to buy a few more in different sizes. The Model Rocket Shop and Semroc's web site show different barrel type

baffles, so I assume that this baffle is now OOP.

Construction:

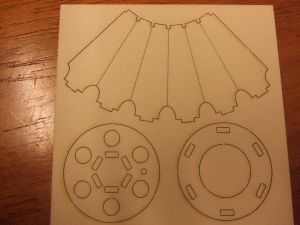

The picture on the web site showed a completed baffle and that's what I thought I had purchased. What I got was a

sheet of light ply that had been laser cut in a plastic bag. There were no instructions but there is not a lot to do in

the construction. The pieces popped out easy and 1 minute later the baffle was completed, I glued it together with

white glue.

Flight and Recovery:

I glued the baffle into an Estes Rainmaker, choosing an average rocket to see how the baffle worked. I did not want

to ruin a good rocket if anything went wrong. There are no instructions on where to glue the baffle in the body tube. I

opted for as high as possible that still allowed room for a parachute. Baffles can shift the CG lower so I had to check

stability but everything was fine.

The rocket flew normally and at ejection the nose cone and recovery system deployed, so no problems there. On checking the parachute, there was no pin hole burns or significant melts. There was a slight char to a small patch of the chute so I guess the baffle does its job to a reasonable standard but I will still use a back up of a swatch of Nomex® in the future.

Summary:

Now I've tried a baffle and I like them, but there are pros and cons.

PROs: Eliminates the need for lots of wadding, which stops wadding being spread across the countryside and speeds up prepping the rocket.

CONs: Relatively expensive compared against reusable wadding that can be moved between rockets.

|

|

M.G. (December 9, 2008)

|

|

G.H.G. (October 17, 2007)