| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

Brief:

This is a reproduction of the 1968 Astron Nighthawk (K-34) boost glider. The canard-style glider, with "M" type dihedral, flies very well and is probably the best performing glider Semroc offers.

Construction:

The xKit concept is basically just a bag of parts, no instructions, though the header card offers a URL where the Jim Z scans are archived. The parts are excellent quality, and include:

- Pod

- BT-20 body tube

- BNC-20B balsa nose cone

- Laser-cut balsa fins (pair of 4-piece)

- Laser-cut balsa pylon

- rubber shock cord

- 12" plastic chute

- 1/8" launch lug

- Glider

- Laser-cut balsa fins

- Laser-cut balsa fuselage/body

- Lead weight

- Waterslide decals

Since there are no instructions provided with the xKit, you'll need to go to JimZ's archives for a set of the Estes originals, available in both .TIFF and .PDF format. Those instructions are very old-style (1968), and as such are black and white. The illustrations are hand-drawn and a bit fuzzy through the scan. I would rate this overall about a 3 on the 5 point difficulty scale as the glider itself and the pod fins get to be a bit tricky. Also, this might just be me, but even though I've built many gliders, they have generally been followed more modern designs and processes so this particular kit had me scratching my head a couple of times wondering what I was supposed to be doing.

The construction is simplified a bit through the use of laser-cut parts versus hand-cut from templates. In particular, there are a few spots where Semroc included a laser-etched scribe line on the balsa to assist in bending parts such as wing dihedrals without breaking them.

Construction begins with the fuselage assembly. This was one of those points where I struggled a bit comparing to my modern experiences--the fuselage is comprised of two matching balsa parts that are glued together rather than a single piece, but before gluing them each must have a small section cut out to form a slot. Later on, a small weight is inserted into this slot. Carve carefully, as you'll still need an outside wall on each piece to hold the weight in place. Each half also gets a slot cut all the way through, used later to hold the pod locking/receiver pin during boost. Glue the two mating halves together, and the fuselage is done.

Next up comes the wing assembly. The wings are laser-cut, and the mating halves are glued together with a single V dihedral. A cardstock template is provided to assist in setting the correct angle. Note that I said a "V" dihedral here but earlier described it as an "M" dihedral. That's because after the wings are set, you need to sort of crack the tips of each and bend them downward. The original instructions describe carefully carving out a V-shaped notch and then cracking the balsa to force the bend, but on the Semroc part this line is already lightly scored via a laser. I've had to do similar bends on other balsa parts and tend to do this the opposite of how I'm supposed to--rather than treat the score line as the inside of the formed angle, I treat it as the outside. Whenever I try pulling up/in against that score line, I invariably crack the other side and wind up with two distinct pieces instead of one formed piece. In this case, that left me with a large cavity or groove along a critical wing joint, so I filled it with a bit of glue and CA'd a reinforcing piece of light fiberglass over it.

Once you've mastered the dihedral/wing tips, you get to sand in the funky airfoil. Considering how tricky this was working with the already angled wing parts, I would strongly recommend putting in the airfoil before building the wing. The airfoil on the top surface calls for only tapering down from about 1/3 of the chord forward to the leading edge, not trailing edge taper. On the underside though, you airfoil from the back third of the chord to the trailing edge. I trusted it and it seems to work, but it's very different than any airfoil I've used in the last 5-6 years...

Attaching the wing to the fuselage completes the glider assembly other than trimming for flight.

The pod assembly is fairly simple although it's a bit more complex than the booster pods I've worked with before. For starters, it has fins (canards), which are needed to prevent a looping boost. The construction involves attaching a metal motor hook, held down by a cardstock cover plate then building a pylon for mounting to the glider. The pylon is a pair of balsa halves (not one piece...), with grooves notched in each half to accept the 1/8" dowel pin used to hook the glider. The pin is then glued in, and a pair of balsa plates are tacked on hanging below the bottom. These keep the glider fuselage locked in place and prevent the glider from twisting off during boost (or while catching a breeze on the rod). A long 1/8" launch lug goes in the fillet joint against the body tube.

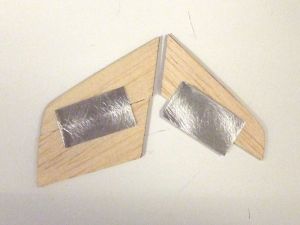

The canards are a neat little assembly consisting of 4 pieces each side--upper and lower with front and back halves. You start by gluing a small piece of metal foil to a bottom/front section, then gluing the top/front section on top, with half the metal foil sticking out. This half gets bonded to the back/bottom piece, and then sandwiched in by the top/back piece. The back pieces are just a hair shorter than the front halves, so that when you bond the assembly to the body tube, only the front half touches. The back half can be adjusted up/down by hand, adding a slight amount of incidence for controlling the boost. The directions call for very minor tweaking of his angle--starting with no more than 1/32" up or down incidence.

To trim this for flight, the suggested CG for the glider is way back, about an inch from the trailing edge. This will generally require some nose weight, and Semroc provides a nice little piece of lead that can easily be bent/broken and inserted into the fuselage slot as needed. I wound up using about 3/4 of my piece to get the balance point far enough forward for a decent hand glide.

Finishing:

Gliders in general should be built light, and this certainly means no Elmer's Fill 'n' Finish and usually no paint. In this case though, I wanted to at least give it a little white to make use of the decals included in the kit plus make it a bit more visible in the taller grass I tend to fly in. I went with one light coat of white primer, followed by two coats of gloss white. I made one very big mistake in construction though by using a Sharpie to draw my airfoil reference lines. I had sanded most of the mark off, but not all, and I could have probably added another 4-5 coats of paint and still not made it completely disappear.

The waterslide decals go on the glider itself and are a basic bird profile with wing, eye, and beak. They look nice, but the wing overlaps the slot cut out for the dowel pin so there will surely be some tearing in the future.

Construction Rating: 4 out of 5

Flight and Recovery:

I had finished this one up right before our club was holding a B-boost glide contest, and while I wouldn't think of this as a very competition-worthy model, I decided to take it along for at least a practice flight. With very strong winds, gusting to 20mph but "lulls" around 12-14mph, I began to look at this as much more competition-worthy than my lighter models which would have trouble and probably get knocked around too much to glide. I decided to put this one up on a trim-testing 1/2A6-2 to see if it could climb in the high winds and to see how the glider would perform.

Normally with a boost glider, you want it on the rod with the pod upwind of the glider. Despite the fact that this design has a strong grip between the pod and glider, it tended to get blown off on my walk back to the range head, so I turned it around with pod downwind.

The downwind orientation hurt it on boost, as the wind pushed the glider under the pod, pulling it away during the boost, so I only got about 30 feet of altitude. The boost was straight as an arrow though, which was great news.

With such a wimpy boost, I wouldn't have given the glider much chance, but it leveled out almost immediately into a glide, turned downwind, and began racing away. It did very well, losing altitude very slowly, and drifted about 150 feet downwind. I recovered everything and carefully packed it back in the car, having found a great little B-boost glide candidate if the winds for the next day don't ease up.

Flight Rating: 5 out of 5

Summary:

PROs: Solid performer, flies fine, and classic appeal.

CONs: Slightly more difficult to build than it needs to be, canard trim is probably overkill, and decals cover the fuselage cutaway area.

Overall Rating: 4 out of 5

Other Reviews

- Semroc Nighthawk (xKit) By Howard Smart (March 14, 2009)

Brief: This is a pod-boosted glider. The unique features include a design that is essentially a flying wing, and forward canard fins on the pod which are adjustable to give a vertical boost. Construction: This is a reproduction of an old Estes boost-glider, kit number K-34. It includes all of the parts of the original, with some substantial improvements. All of the balsa parts ...

|

|