Thrustline Aerospace Starship Electra

Thrustline Aerospace - Starship Electra {Kit}

Contributed by Chan Stevens

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Thrustline Aerospace |

Brief:

This review is for the beta version of the not-yet-released Thrustline kit. Not

to tease you readers too much but this will be a wonderful kit and when it's

released, I'd highly recommend it. It's futuristic design is influenced by the

Mars Snooper, and it is large, graceful, and flies magnificently on E9s. It's

jumped onto my top-ten list of favorite kits.

[Note: Because this is a beta, I'm including a few gotchas along the way that are extremely unlikely to occur in the finished product, as the build was coordinated with Thrustline every step of the way.]

Construction:

This kit has a fairly extensive parts list:

- Balsa nose cone, NC-55 Honest John style

- 3 BNC-5 cones

- 3 BT-5 inner pod tubes

- 3 BT-20 outer pod tubes

- 2 BT-55 body tubes 12.25" each

- BT-70 body tube

- BT-50 motor tube

- E-sized metal clip

- Assorted plywood, fiber, and cardboard/paper centering rings

- 1/8" and 3/32" Balsa fin stock sheets

- Kevlar®/elastic recovery cord

- Mylar chute

- D/E motor adaptor kit

Parts were all very good quality although the balsa stock is a bit soft. The instructions were generally very good but contained a few beta-related typos. They were packed with lots of color photos, including an indexed parts photo to help you sort out the bag of stuff as you go along. Overall, I'd rate this about a skill level 3 kit as there are some slightly challenging techniques involved and a potentially complex paint scheme.

Motor mount construction is fairly straightforward, however, this kit included an unusual reinforcement method. Most kits use either masking tape or a centering ring to hold the metal clip in place. This kit includes a BT-50 sleeve which is slit and then slid over the BT-50 motor tube and glued in place. This is definitely going to outlast masking tape, but I found it to be slightly overkill (and ironically, my motor mount blew out on flight #3 after a very violent ejection charge).

Next up is construction of the side pods. These are actually somewhat intricate assemblies, not ordinary BT-20 pods tacked onto the fins. The assembly consists of a center BT-5 tube, which has a couple of CR5-20 centering rings attached. A BNC-5 cone is then glued into place and the BT-5 assembly is then glued into a BT-20 tube. This leaves a part of the BT-5 sticking out the aft end and the BNC-5 sticking out the forward end for a nice layered look. The look is finished off with a boat tail shroud cut from a paper pattern. There are extra patterns printed, so there's plenty of recovery room for goofs. (In fact, my kit had more than double the required amount.) My shrouds fit fine but they had goofy and unnecessary tabs on both ends. One tip I'd offer for these (and for paper shrouds in general) is to use only rubber cement or white glue for bonding and then paint them with a thin CA for firmness.

The main body tube is actually a 2-piece assembly of BT-55s with

a coupler. At 12.25" apiece, I had suggested that this be switched to a

single piece tube, eliminating an unsightly seam on the main sight line. This

makes the bag bigger and shipping more difficult, but this request is being

considered. The current design with the coupler, also includes a centering ring

at the base of the coupler which is used to anchor the Kevlar®

shock cord line. That's very helpful, and keeps the Kevlar®

a foot above the motor, saving it from some of the ejection charge stress.

The main body tube is actually a 2-piece assembly of BT-55s with

a coupler. At 12.25" apiece, I had suggested that this be switched to a

single piece tube, eliminating an unsightly seam on the main sight line. This

makes the bag bigger and shipping more difficult, but this request is being

considered. The current design with the coupler, also includes a centering ring

at the base of the coupler which is used to anchor the Kevlar®

shock cord line. That's very helpful, and keeps the Kevlar®

a foot above the motor, saving it from some of the ejection charge stress.

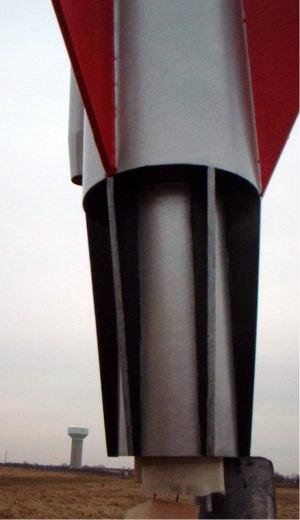

There is a larger BT-70 "outer tube" that slips over the main BT-55 tube, towards the aft end. This is pretty basic, aided by a pair of fiber centering rings in the BT-70. [Note: Any external fillets, as the rings are flush mounted, should be minimal since there are trim fins that butt up against the centering rings.

Next in the build comes the tube marking for the BT-55s, BT-20 side pods, and the BT-70. I suggest doing this before they're bonded together, but bonding afterwards is still possible. My kit had a whoopsie on the larger marking guide--it was sized for a BT-60, not a BT-70--but I was able to whip one up very quickly using RockSim.

Depending on how you look at it, cutting out the fins is either

a pain or a pleasant mini-project (if you consider yourself old school and

prefer slicing your own). There are 30 different fins/pieces to cut on this and

all from pre-printed patterns. While it might add a buck or two to the cost of

this kit, this really might be a nice application for laser-cutting, especially

given the numerous curves and angles involved. Many of the pieces are not

symmetrical and therefore can't be cut back to back with a common line. Six of

these fins go aft of the BT-70 outer tube and six go forward of the tube. I

wound up deferring the bonding, wanting to paint them first. (I took the time

to mask off a line for bonding too).

Depending on how you look at it, cutting out the fins is either

a pain or a pleasant mini-project (if you consider yourself old school and

prefer slicing your own). There are 30 different fins/pieces to cut on this and

all from pre-printed patterns. While it might add a buck or two to the cost of

this kit, this really might be a nice application for laser-cutting, especially

given the numerous curves and angles involved. Many of the pieces are not

symmetrical and therefore can't be cut back to back with a common line. Six of

these fins go aft of the BT-70 outer tube and six go forward of the tube. I

wound up deferring the bonding, wanting to paint them first. (I took the time

to mask off a line for bonding too).

The main body fins are a somewhat complex 4-piece assembly. Pay careful attention to the pattern sheets and you'll have no problem, but one of the triangular sections is a bit easy to orient the wrong way. With 3 seams and grain going in all sorts of different directions, these were a real pain to sand and fill. Even after 3 coats of Elmer's Fill 'n' Finish, I still have visible grain, but it's only noticeable upon very close examination. I would also note that the stacked root length of the fin patterns was about 1/4" too long and will no doubt be corrected before the final release.

Last up on the fins are a set of 3 dorsal fin/canards and a set of 3 very small pod trim fins. Pay careful attention when bonding these fins as the main body fins look like they're on backwards and they look this way on purpose. I bonded all my various fins using CA to tack them in place and then used yellow glue for fillets. Once the main fins are attached, the side pods get tacked to the main fins then trim fins to the side pods.

The nose cone is attached using a screw eye and elastic shock cord, which is tied to the Kevlar® just inside the body tube for a zipper-free design.

Finishing:

John and I debated several different paint schemes before I ultimately cheated

and went off to paint it on my own. I was delighted with the appearance of my

Squirrel Works Astrid and wanted to use a similar scheme on this one. So after

applying 3 very light coats of primer (be careful to avoid runs--there are lots

of nooks and crannies on this), I went with a base of Rustoleum Silver

Metallic. I'm not talking about the solid/mirror finish, but the stuff that has

a flaky/glittered look to it. I then trimmed most of the fins using a similar

red metallic flake paint. All six aft trim fins were painted gloss black, as

were the BT-70 and BT-55 centering rings. Finally, the BT-5 nose cones were

painted orange. I'm not sure I like the orange, but I had no idea what else to

go with at the time.

As noted previously, I painted the trim fins before bonding and wound up bonding them using a tiny amount of CA followed by a fillet of Elmer's white glue, which dries clear.

Decals are not currently available for this, although a design is in the works. I'd like to see something adding a royal blue to this along with a couple of long trim lines and possibly some type of cockpit detail.

Construction Rating: 4 out of 5

Flight:

The recommended motors are D12-5 and E9-4. For the first flight, I chose to

jump straight to the E9-4. The flight was unstable and it crashed still under

impulse. Fortunately, there was virtually no damage. After a couple of email

exchanges, we decided to add some nose weight. I wound up attaching about 1.5

ounces of washers to the nose cone (by replacing the screw eye). I also scaled

back down to a D12-5 and tried again the following weekend. This time in

heavier winds of about 10-12 mph, it flew fine and deployment was right at

apogee. After slipping off into contest flights for a couple months, I got

another chance to fly this on an E9-4 twice. Each flight was wonderful--long,

slow, and straight as an arrow (not even a hint of spin on the way up) with

deployment right at the top. The nose weight made all the difference.

Recovery:

The beta kit included both an 18" and 20" mylar chute, asking me for

feedback on which to use. I mainly used the 18", but I fly on a field with

very tall (2-3 feet) grass and even when I completely forgot to pack a chute

one time, soft landings are the norm. For short grass flying, I'd probably go

with the larger 20 or 24" chute, as the large fins could be prone to

breaking with the mixed grain directions.

Flight Rating: 5 out of 5

Summary:

I found this to be a beautiful rocket with awesome flights on my favorite

motor, the Estes E9. It's definitely an unusual and appealing design and a

break from the typical commercial fare. The main PROs are design, performance,

and quality of instructions and materials.

The only CONs would include soft balsa with lots of hand cutting, the two-piece body tube, and (beta only) lack of decals.

Overall Rating: 4 out of 5

|

|

Flights

|

|