| Manufacturer: | Modification |

|

Beg Birtha

Anyone remember Rocket Services? No? How about "Pitfield" motors? Ah, thought some of you might. Well, we don't see them around so much as in years gone by, but there are still a few around. In fact, I stumbled across a cache of them recently and thought I should build something to fly them in. I'd never actually flown a Pitfield motor before. Watching other people's flights had always put me off a bit. The rockets always seemed to be underpowered, and had started to descend while still under thrust. Who can forget Rick Newlands spending almost the whole of UKRA 2000 sanding a nose cone from a balsa tree trunk, only to have the Pitfield powered rocket arc over while still under thrust? (Sorry Rick!) So I wanted to avoid overbuilding at all costs.

So what to build? At IRW 2003, I entered a PMC (Plastic Model Conversion) of the Airfix Saturn V. Though it didn't quite fly as intended, it took joint first prize, along with Mike Crewe's Mercury Redstone. Our prizes were matching Big Berthas. We'd agreed we would build them with a common theme, and drag race them. Initially it was to be a cluster, but, when we came into the stash of Pitfield motors, we had other ideas. You see, BT-60 is exactly the right inside diameter for an F36-5 motor mount. Beg Birtha was born.

|

Simulation

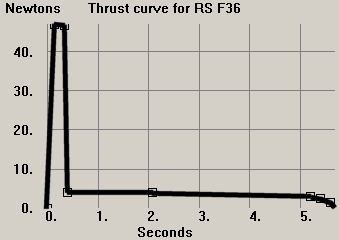

It was easy to modify a standard Big Bertha Rocksim File. I just removed the motor mount and added a new thrust ring. I made some rasp-format engine files for the motor, using the engine editor that come with Rocksim. I got the thrust curve, and data from an old Rocket Services catalogue. You can download both the Rocksim file and the engine file here:

http://www.nsrg.org.uk/data/beg%20birtha.rkt/

http://www.nsrg.org.uk/data/rs.eng/

I should point out here, that Rocket Services' motor designations, do not correspond with the more common "Estes-style" designations. The "F36-5" should, strictly speaking, be known as E6-5, and the "F72-0" is, in reality, an E15-0. Having said that, Estes aren't always consistent themselves. If you don't believe me, look at the thrust curve for the A10 mini-motor sometime.

|

Build

This really is a straightforward build. The differences from the stock kit may be summarized as "leave out the motor mount and add some nose weight". But, because I know our beloved newsletter editor will appreciate the extra column inches, I'll spell it out in full:

I skipped Step 1, Engine Mount Assembly, and put the parts in my spares box. Instead, I made a new thrust ring from a short section of toilet roll core, reduced in diameter by removing a segment. You could also use a short length of coupler, or cut a ring from a spent motor.

I completed Step 2, Shock Cord Mount Assembly, as instructed. I chose to do Step 9, Shock Cord Mount Attachment, at this point, while the mount was freshly-glued and still pliable.

Step 3, Fin Preparation, was completed as normal. Step 4, Engine Mount Installation, was omitted. Step 5, Tube Marking Detail, Step 6, Fin Attachment, Step 7, Launch Lug Attachment, & Step 8, Glue Reinforcement Detail, were all completed as per the instructions. Step 9 was completed earlier.

Step 10, Parachute Assembly, was skipped. Instead, an approx 100mm x 1000mm streamer was made from the finest Deepsky mylar. This was attached directly to the shock cord, rather than to the nose-cone attachment point.

Step 11, Painting Your Rocket, was done as directed. For Step 12, Parachute And Shock Cord Attachment, I deviated from the instructions, to add the additional 20g of nose weight.

|

Flying

The first flight was on the occasion of my first attendance at a WRS (Wirral Rocketry Society) launch, on 10th April 2004. I thoroughly enjoyed this launch, a relaxed, convivial atmosphere, and a great bunch of Rocketeers.

Because I omitted the original motor mount, there was no retainer hook - it wouldn't be long enough anyway. So friction fit was the order of the day. And you do need to make sure it's a tight fit, you really don't want a spent Pitfield motor landing on your head! The F36 has an enormous nozzle, and I was a bit worried that an Estes igniter might get lost in there. So I used some QuickMatch, pushed all the way in, taped to the motor body, with an Estes igniter on the exposed end. It was only about 60mm of QuickMatch, and when I pushed the button, ignition was pretty much instant. Beg Birtha fairly leapt from the pad, so quickly that I don't think anyone managed to get a picture. The motor thrust decreased, but kept burning almost up to apogee, the orange glow quite visible. This would be a great rocket to fly at dusk.

Conclusion

This was a fun conversion, of an already classic rocket. This is certain to become a favourite flier of mine, at least until the motors run out. Can't wait to try it out at the IRW, which, to me, is the spiritual home of the Pitfield motor. If you took a look at the Rocksim file, you might have noticed that there's a design for a booster stage in there too. I haven't built or flown this configuration yet, but I do have some F72-0s...

#Related Reviews

- Modification Ahtreb By Dennis McClain-Furmanski

Brief: Big Bertha modified for rear ejection. Modifications: This is a Big Bertha modified so that the motor tube extends nearly the length of the body, and acts as a piston upon ejection. Recovery is nose first, making the rocket appear to be coming in upside down. I call it Ahtreb, which is ...

- Modification Big Bertha Payloader By Karl Upton

How To Convert An Estes Big Bertha Into A Payload Rocket Purpose and Design I need a series of payload rockets to carry experimental flight recorders/dataloggers into the Troposphere. The BBPC is something I came up with after a scratch-build payload rocket project that was enjoyable, but ...

- Modification Super Baby Bertha By Kevin Johnson

Took a Fat Boy kit and added Big Bertha like fins to make a Super Baby Bertha. Modifications: NARHAMS held a Fat Boy theme sport launch this month, and I was looking for something different to do with my last Fat Boy kit. I had just finished repairing my Super Big Bertha when inspiration ...

- Scratch 2x Big Bertha By David Fergus

This is a scratch 2X upscale of a popular Estes kit. It features a 3 inch diameter body and PML components (except the nose cone, which was turned on a lathe out of solid pine). It weighs 3.5 pounds and is 45 inches tall. A 36" long, 3" diameter quantum body tube was ordered with fin slots ...

- Scratch Big Bad Bertha By Bob Fortune

Big Bad Bertha Premise: Find out how bad Bertha can actually be. Fun Facts Just because your jaws are wired shut doesn't mean milkshakes aren't part of the food pyramid. That's not a stool she's sitting on. Starting point: Estes Big Bertha ...

Related Products

|

|