Fat Cat Rockets I.P.F.I. Strikeship

Fat Cat Rockets - I.P.F.I. Strikeship {Kit}

Contributed by Nick Esselman

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar |

| Manufacturer: | Fat Cat Rockets |

After holding the Fat Cat's Name This Rocket and Story Contest over this sleek, futuristic looking rocket, I decided to purchase one at Fat Cat's special introductory price. You should check out the contest stories. They are great. Fat Cat's decided to combine the suggested names from the top three winners and came up with the I.P.F.I. Strikeship "Lightning". I call it the Strikeship for short.

Fat Cat Rockets says that they "stock 18 of the most innovative, custom rocket kits on the market" and so far, in the mid to high power range, I agree. The Strikeship is truly an example of this. The kit is currently priced at $44 (as of July 2003). This may seem like a bit for a rocket, but compare it to a straightforward, entry-level, mid-power PML IO at $47 or to another 29mm futuristic bird, the LOC Delta Strike Fighter at $38, then the $44 price tag is not too bad. Then look at everything you get, and you will even be happier.

The kit two 12" 29mm tubes and one 7½" long, 2½" diameter body tube, two 29mm wooden nose cones, pre-cut 1/4" balsa wings, 5/32" balsa fins and rudders, a balsa canopy, various dowels, two wooden gunpods, fiber board strips, and nose weight. The recovery system is made up of a steel leader with loop-clips, 65" of ½" black elastic stock cord and a 24" rip-stop parachute. There are also four plywood centering rings , the 29mm motor tube, and launch lugs. Lastly, the kit includes some ready-stick decals. The materials were packed well and are of high quality.

CONSTRUCTION:

The instructions are printed on 6 pages of 8½ x 11" paper and there were two additional pages with decal placement and color schemes. The instructions had color-coded illustrations that really assist the builder in seeing the various parts. They were in a logical order and easy to follow. I did find one mistake, right in step 1. It indicated the upper centering ring had two holes in it (like their other kits). When I noticed my upper centering ring did not have two holes in it, I drilled two holes, only to fill them in with epoxy later. The only other enhancement that could be made to the instructions is to cut the launch lug to size and angles that match the lower fins. Not a big deal at all.

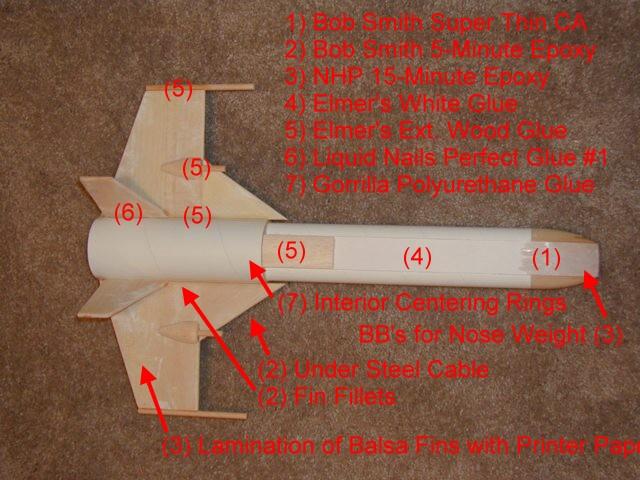

The instructions indicate that you need epoxy and CA, but I used 7 different glues in my build. Check them out. I'm sure epoxy and CA work just fine!

Plan on spending a few days assembling the Strikeship. Go ahead, make it a winter project! The instructions will guide you through nicely, however, there are some unique challenges to building this rocket. As I discuss the build, I will highlight some of the unique areas and challenges.

Like the Galactic Marauder, the rocket is assembled in two sections. First the forward section, then the aft.

The forward section starts by gluing the two 29mm body tubes together (I used Elmers Exterior Wood glue). Then the provided nose weight (BB's) are glued into the hollowed out wooden nose cones. I split the BB's in half and filled each nose cone equally. I then used 15-minute epoxy and keep adding it until all the gaps were filled and I had a nice smooth top on each nose cone. The nose cones are then glued into the two motor tubes. On the opposite end of the nose cones, two centering rings are attached. Both fit perfectly without any sanding.

Next, Fat Cat warns, "This part of constructing the model can be tricky. Take your time and be careful." This is the placement of the fiber boards on the top and bottom of the dual-cone forward section. I used Elmers White Glue for this and found that using some masking tape to hold everything in place was necessary. I also allowed the top to completely dry before doing the bottom. I really didn't have trouble with this step, except that my masking tape torn a bit of the fiber board surface off. I ensured the seams were filled using Elmers White Glue and my finger to ensure I did not get globs or that the clean, sharp edge of the fiber board was messed up.

Next, Fat Cat warns, "This part of constructing the model can be tricky. Take your time and be careful." This is the placement of the fiber boards on the top and bottom of the dual-cone forward section. I used Elmers White Glue for this and found that using some masking tape to hold everything in place was necessary. I also allowed the top to completely dry before doing the bottom. I really didn't have trouble with this step, except that my masking tape torn a bit of the fiber board surface off. I ensured the seams were filled using Elmers White Glue and my finger to ensure I did not get globs or that the clean, sharp edge of the fiber board was messed up.

To fill the small gap that is left at the tip, I used 5-minute epoxy. I also soaked the section fiber board that covered the nose cone with super thin CA to make it more durable.

The balsa canopy is glued onto the top of this assemble to finish it up. I used Elmers Exterior Wood glue.

Next, the fins are prepared. The main wing is made up of two pre-cut pieces of 1/4" balsa. The fins and rudders are pre-cut from 5/32" balsa. I coated all the balsa fins with 15-minute epoxy, covered with 24lb printer paper, and pressed between wax paper under a heavy book to strengthen them (and eliminate the grain). After this was done, I rounded the corners as instructed and added the various dowels to the wind and rudder edges. I used Elmers Exterior Wood glue to attach the main wings to the 2.6" body tube.

The fins and rudders attach directly to the main wings and not the 2.6" body tube. Placement is described in detail and you use one of the 1/4" launch lugs to assist in placement. I used Liquid Nails Perfect Glue #1 for the initial attachment. The gunpods are also glued directly onto the main wings.

Attaching the steel leader cable is a unique step in building the Strikeship. You see, this is a rear-ejection system and Fat Cat opted to attach the steel leader cable to the outside of the body tube. This is done in the gap between the body tube and one of the lower fins. Using masking tape to make a dam, and then using a lot of 5-minute epoxy, you attach the leader cable. (see picture, right side of body tube)

Attaching the steel leader cable is a unique step in building the Strikeship. You see, this is a rear-ejection system and Fat Cat opted to attach the steel leader cable to the outside of the body tube. This is done in the gap between the body tube and one of the lower fins. Using masking tape to make a dam, and then using a lot of 5-minute epoxy, you attach the leader cable. (see picture, right side of body tube)

The launch lug is attached on the opposite side between the body tube and the other lower fin. I cut my launch lug so that it was the same length and used the same angles as the lower fin. This was not described in the instructions, but I think improves the looks. A notch is made in the rear of the body tube to allow the cable to go inside body. (see picture, left side of body tube)

The motor mount is actually built in the very first step and is straightforward; motor tube and two centering rings. I added a Rowes Retainer 29mm retainer, as can be seen in the photos. It was very easy to add.

To finish the recovery system, the final loop is put into the steel leader and the elastic is tied to it. The other end of the elastic is tied to the motor tube and the parachute is attached onto the elastic near the motor mount.

There is one other section of assembly that should be mentioned; the nose strut. This is only for display only and is designed to be removable from the underside of the forward section. It is used to display the model so that the forward section is help up parallel with the ground. Landing gear, so to speak. A nice "extra" touch.

Finishing this rocket, if you want to have a nice finish, takes a lot of work. I had no less than 7 coats of Plasti-Kote primer on it and various spot work with Bondo Glazing. This is needed for the roughness of the wooden nose cones and gun pods, the spirals in the body tubes, the filled nose tip, the dowel seams, and the various other joints. It is worth the time for a rocket like this! I didn't use either of the two paint schemes that Fat Cat Rockets suggested. Instead I used a metallic light blue automotive paint. I like the finish.

The decals are stick-on. I have one complaint on the "double doors" sticker that you are instructed to cut in half. The line to cut on is the same thickness as the outside lines so if you cut on this line you loose the line that you cut on. The instructions note this and tell you to cut it in such a manner that makes one set of doors complete and leaves "open hinges" on the other. They then say to use a black pen to draw in the missing lines. I hope future decal runs separate them so other builders don't have to draw in the lines. Other than that, I like the decals and they add a nice look to the finished kit. The cockpit decal is cut from a glossy black sticker and placed on the top and sides.

After I did the decals and waited 3 days (for drying purposes), I did three very light coats of Clear Coat (Walmart brand). Then one full and heavy coat. The 3 days drying time and light coats help guard against paint reactions.

Overall, for CONSTRUCTION I would rate this kit 4 ½ points. The instructions are clear and logical and you certainly get quality parts. Everything fit on the kit! No sanding was required, even for the centering rings. To be consistent, I have to ding the kit slightly for not having positive motor retention.... I know this is common for mid and high power kits, but perhaps the manufacturers will start adding it as an option. Also, I was bothered by that "double door" decal. Neither of these items are that big of a deal and therefore the rating of 4½ will still show that this is a solid kit.

FLIGHT/RECOVERY:

FLIGHT/RECOVERY:

Fat Cat Rockets indicate the Strikeship should weight 20 ounces. My finished kit weighs 19.4 ounces. Not bad, eh?

Fat Cat instructions only recommended one motor, the F50-5 (which they must have meant F50-4). However, shortly after purchasing it, Fat Cat sent a "correction" e-mail that addressed a couple of items, including the recommended motors. They now say, "The motor listing is a suggestion, F40 to F62 should work as well with a 4 or 6 second delay".

I planned my first flights of the Strikeship. First an F50-4, then an AT RMS F52-5.

Preparation was easy with the rear-ejection system. It doesn't require any wadding either, since the centering rings protect the parachute and shock cord. I had no trouble getting everything packed into place. I then taped my F50-4 motor, slid it in and used the Rowes retainer.

The first flight was great. Don't know if I have any other words that work here. It zipped off the pad, I missed the shot, well, kind of... caught the tail as can be seen. It was very stable and gave a nice looking flight. The ejection was a bit early, too bad AT didn't make that F50-5! Descent was fairly quick. I ran to catch it and boy did I. Right in the chest. Gained a nice little welt from the wing hitting me. After all, it is 20 ounces!

The first flight was great. Don't know if I have any other words that work here. It zipped off the pad, I missed the shot, well, kind of... caught the tail as can be seen. It was very stable and gave a nice looking flight. The ejection was a bit early, too bad AT didn't make that F50-5! Descent was fairly quick. I ran to catch it and boy did I. Right in the chest. Gained a nice little welt from the wing hitting me. After all, it is 20 ounces!

My second flight was on the RMS F52-5. Another roaring lift-off and great flight, but the 5 seemed to come in at 3 seconds so the Strikeship still had a good head of steam when ejection occurred. The rear-ejection system paid off and allowed the parachute to deploy without any zippering damage. Recovered and it is ready to fly again! I have one F50 left but need to find some F52's! I may try an F23, G33 or G64.

For FLIGHT/RECOVERY, I would rate this rocket 5 points. It flies great! It is wadless! It recovers great! Nuff said.

I give the rocket an OVERALL rating of 5 points. Fat Cat does produce "unique" kits and this is one of the best (to me). I love the design and am planning a few variations of it. I will be making a 2x24mm cluster motor mount for it and purchasing two more kits for modifications. I'll have an I.P.F.I. Strikeship fleet. This one is nicknamed "Lightning" according to Fat Cat Rockets. I think I have the "Tornado" and "Thunder" as well! We'll see.

Other Reviews

- Fat Cat Rockets I.P.F.I. Strikeship By David Fergus

Summary: A fantasy futuristic single pilot space fighter. It has a unique fuselage shape, flies on 29mm motors (F50 is the only motor recommended by the kit maker) and has rear ejection parachute recovery. This rocket was named in a contest sponsored by EMRR. The name was a combination of the top three vote getters with IPFI being the abbreviation for InterPlanetary Fighter In ...

|

|