Polecat Aerospace Nike Smoke (5.5\\\")

Polecat Aerospace - Nike Smoke (5.5")

Contributed by Taylor Jessee

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar |

| Manufacturer: | Polecat Aerospace  |

Brief:

At the end of last year, I decided I needed a 54mm rocket. I looked through a lot, and this rocket seemed the best as

far as getting "more bang for your buck". Having had a Nike Smoke from Quest in the past and liking military

kits, it appealed to me a lot. It is the standard dual deploy rocket, but all the recovery goes in the nose.

Photo courtesy of Polecat Aerospace

Construction:

In the box, I found:

- 1 54mm Motor Tube

- 4 Pre-beveled Fins

- 2 15' Shock Cord

- 1 enormous Fiberglas Nose Cone

- 2 5.5" Body Tubes

- 3 nicely cut Centering Rings

- 1 Electronics Bay Assembly

I didn't really look at the instructions at all, however, I built it completely stock. I also made huge fillets. I amazingly said that it could come out at 5.5lbs. Mine came out at over two times that by coming out in the 12-13lb range (without parachute).

It didn't come with any sort of motor retention, so I rigged up my own with blind nuts and the proper bolts and washers. It has worked nicely so far.

I didn't like the amount of tubular nylon (TN) that they gave me, so I linked the two 15' pieces together and added another 20' of my own for the main. I like my cords really long!

I added about 10oz of nose weight secured with expanding foam just to be on the safe side. I cut up pieces of solder to do this with. I also thought that the way of securing the shock cord in the nose was slightly different as well with a 4" bulkhead glued in.

Finishing:

Polecat used to give you nothing at all but have since upgraded certain kits to come with decals. I lacked any other

scale data. I sanded the glass smooth but not completely, as the glass line is still faintly noticeable. I painted it

in the normal white, red-orange, and yellow. It turned out very nice. I put both of the decals on opposite sides.

Thinking I could put them on easily, I didn't do the soapy water trick and applied them on the dry body tube. They came

out slightly crooked but nothing extremely noticeable. After that I applied a few coats of clear coat.

Construction Rating: 4 out of 5

Flight:

It says I can fly on H-L motor but the smallest I would put in is a high thrust I. I was very nervous for my first

flight. I went to the vendor and bought my motor. The K550W was my motor of choice. I loaded it up and put it in the

rocket. Next, I got the electronics ready. I used Christmas tree bulb matches with Pyrodex, because I ran out of

e-matches and black powder. I didn't have any good way to put in a safety switch, so I put the wires through a couple

vent holes, twisted and shoved back in with tape. I got both altimeters armed but one had a wire loose and I wasn't

getting continuity. I had one working, so I just left it as is. I inserted the Quickburst igniter and set off. I was

very tense when he started the countdown. 5,4,3,2,1,launch! I saw a small amount of smoke, a flicker of flame, then it

roared to life and went high and straight up into the sky.

Recovery:

I saw the relief from the puff of smoke at apogee. Then it was coming almost straight down on my Skyangle 28 drogue.

It kept falling and falling. It hit 500' and no main, but then I remembered that one altimeter didn't arm right. At

300' there was a puff of smoke and the main came out. I was using a slightly undersized 66" military surplus chute

because my 72 Tac-1 hadn't arrived in the mail yet. The size didn't matter that much at the low altitude it was at. It

touched down about 200 yards away in perfect condition. Everyone was cheering. It felt good. I went to get it and there

was only a slight dent in the back of the airframe. My grandpa helped me gather my rocket and we headed back. I later

read the altimeter beeps as 4681', exactly the deployment altitude of my RockSim simulation. I wonder how it did that!

Flight Rating: 5 out of 5

Summary:

I love this kit. I also recommend it to everyone who has enough experience. Though I am only 13 years old, I am very

advanced and built and flew this kit through my grandpa's certification. It is worth the $250.

Overall Rating: 5 out of 5

Presented with written permission from RocketyPlanet:

Product Review by Steve Shannon

Friday, March 30, 2007

February is the dead of Winter in Butte, Montana and that's the perfect opportunity to seek warmer climates. Steve Shannon did just that, by planning a family get-away in the sunnier South, just in time for the Arizona Rocket Gathering. While there, he grabbed a Polecat Aerospace 5.5" Nike Smoke kit for a Winter project and this is its story.

Introduction

My wife and I headed South at the end of February to visit my daughter - Montana was cold and Phoenix looked very inviting. I planned this vacation so that I could attend ARG 4 while we were there.

|

Andy Woerner of Polecat Aerospace was one of the vendors at ARG and I have been interested in his kits for a few years now. I asked Andy about them and he showed me the components of one of them. Based on what I saw, I decided to buy one - I like the Nike Smoke.

I looked at the 4 inch and the 5.5 inch kits and decided that for the difference in money, I would prefer to have the 5.5 inch rocket. He has two models: for $200 you can get a single deployment rocket, or for $30 more ($230 total), you get a kit that has most of the parts necessary (except electronics and parachutes) to build a dual deployment rocket. I opted for the latter.

Parts

The kit comes in a single long box. Everything is neatly packaged. The list of materials includes:

- One fiberglass nosecone.

- One four inch bulkhead that fits deep in the nosecone. This bulkhead is pre-drilled for a u-bolt that will be used to connect a shock cord to the nosecone.

- Two pieces of pre-glassed airframe body tube. One is 36 inches long and slotted for the fins. The other is 10 inches long and intended to be used for the avionics bay and main chute compartment.

- One cardboard coupler for use in the avionics bay. I'll talk more about this later.

- One cardboard 54mm motor mount tube (MMT). This rocket is also available with larger motor mounts, but realistically I can afford to fly many more 54mm motors than 75mm or 98mm motors.

- Four plywood fins. The fin edges are beveled, but not tapered to the center like the classic Nike Smoke fin. That did not deter me, but the purists out there will probably prefer something different.

- Three centering rings. One is pre-drilled for the u-bolt that will be used to attach the shock cord. All three are identical in diameter and cut to accept the motor mount tube.

- Two plywood bulkheads for use in the avionics bay. One has a step rabbeted in the edge. This one becomes the aft end of the avionics bay and is removed in order to access the gizmos you load into your avionics bay.

- Two plywood strips that are pre-drilled and a plywood rectangle (7 inches long by 5 inches wide). These parts form the avionics sled and mounts mounts that slide over two pieces of threaded rod.

- A sealed bag of miscellaneous hardware parts, such as the threaded rods, u-bolts, nuts, and washers. I appreciated the fact that this bag was heavy plastic and heat sealed to prevent the loss of parts.

- Two sets of instructions: one for the Nike Smoke and one for the "Dual Deployment Bay." Each set of instructions had a list of parts that should have been included.

|

Four items that were listed in the parts lists were unfortunately not included with the rocket kit. They were the two tubular nylon shock cords and the two rail guides. The screws and standoff nuts for the rail guides were included. I don't consider these missing parts to be a major problem. Over the years I have built up supplies of both. When I get around to it I will send an email to Andy mentioning these shortages.

Assembly Notes

The instructions are simple to follow and the kit assembles very quickly. First I went through the instructions and dry fit everything to see how it would work. I noticed the two slides for the avionics sled had slightly offset holes (the holes on both slides were offset the same amount) so I made sure to line them up the same.

In less than 20 minutes I assembled and epoxied the "Dual Deployment Bay." Then I started on the rocket body.

|

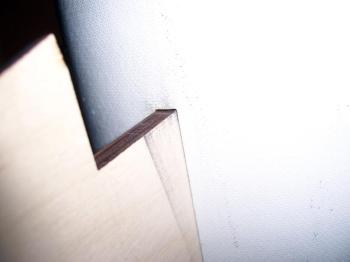

I began by test fitting the centering rings, motor mount tube, and fins. I was very pleasantly surprised by how well the fins fit into the fin slots in the body tube. I honestly have never had fin slots fit so precisely to fin tabs before. The slots were square and straight. When I removed the fins from the fin slots I realized why. The fin slots were (like the fins) laser cut. This sequence of photos at the above right shows the tight fit.

The instructions say to assemble all three centering rings to the motor mount tube (MMT) before gluing the assembly into the body tube and then epoxying the fins in place. Having the aft centering ring epoxied in place would prevent applying internal fillets to the fins. So, you may want to dry fit the aft centering ring until you epoxy the fins to the outside of the body tube and then remove the aft centering ring and applying fillets where the fin tabs pass through the body tube and where they meet the MMT. That's what I did.

|

Put some tape on the aft centering ring so you can pull it out of the body tube after the middle centering ring epoxy and external fin epoxy has cured. Then epoxy the fin tabs to the MMT. Once that has cured apply a heavy band of thickened epoxy just below the fin tabs on the inside of the body tube and on the bottom of the fin tabs and slide the aft centering ring in place.

The forward centering ring fits up at the very front end of the MMT, deep inside the body tube. I have no problem with that although I prefer the coupler at the top of the body tube in the "zipperless" fashion. The middle centering ring sits on the top of the fin tabs. That is fine also. However, the fin tabs are 5-5/8ths inch wide and the directions call for the middle and aft centering ring to be epoxied to the MMT about 9 inches apart from each other. That means that the aft centering ring, which is flush with the aft end of the body tube, would not seat against the bottom of the fin tabs.

|

This is probably a philosophical difference, but I prefer that the thrust of the motor not be supported solely by the epoxy joints on the MMT and centering ring. I want the thrust to be coupled from the end of the motor mount directly to the aft centering ring, then to the base of the fin tabs. The fin tabs then couple the force to the airframe.

With that in mind I had a few options: I could just build it stock and count on the cardboard to handle the thrust of a K. I could slide the MMT farther up into the body tube and then slide the aft centering ring further up so it rests against the bottom of the fin tabs. That will leave the motor firing about three inches up inside the body tube, so I might want to shorten the aft end of the body tube a little also.

Instead, I slid one centering ring up against the bottom of the fin tabs and epoxied it in place. I will apply an epoxy fillet to the centering ring this week. I will put in a short piece of four inch phenolic tubing and add a four inch centering ring flush with the end of the body tube and rocket. That will reinforce the motor tube and also allow me to use the Nike Smoke as the sustainer in a two stage rocket someday.

|

The only assembly that needed to be done on the nosecone was to epoxy in a four inch centering ring which holds a u-bolt. One of the shock cords gets connected to this. I plan also to paint the inside of the nosecone with some Aeropoxy to help seal the exposed glass fibers, which I will discuss in the Materials, Fit, and Finish section which follows.

Materials, Fit, and Finish

The fiberglassed body tube was very well done. The seam on the outside of the fiberglass is visible, but not at all bothersome. Andy recommended lightly sanding it, but I am of the school that believes in building up rather than sanding off. The fine weave of the cloth will make it very easy to fill and sand before painting. In fact this may be the perfect kit to try out some of that urethane spray filler/primer I bought from the car place.

|

The centering rings, fins, and bulkplate were all extremely well cut, fitting very precisely. I have never seen parts that fit so well, with no gaps or tight spots that need sanding to make fit. The wood parts are all high quality Baltic birch plywood with no patches or knots in the veneer.

The nosecone is a nice looking fiberglass component that appears to have been laid up in a two piece mold. The seam where the two halves come together bulges slightly on one side.

Looking toward a bright light from inside the nosecone, one can see where the seam passes more light. The photo below demonstrates that. The material seems heavy enough, but coarse on the inside. After working in the inside of the nose cone to epoxy in the bulk plate my arms were very itchy from contact with the rough glass fibers that are exposed. However, for the price of the kit this is a huge nosecone, standing 32-1/2 inches from the bottom of the shoulder to the tip of the nosecone. It is not coated with a glossy gel coat, but rather with a matte finish which actually will make it easier to prime and paint.

The cardboard used for the dual deployment bay coupler is a decent grade of cardboard. It could be slightly heavier, but it will be adequate. After a trial flight I might want to glass the inside of the bay, but I will try it stock at first.

Synopsis

This rocket is a nicely made kit that assembles easily. The fit and finish of the fins, fin slots and centering rings made it fun to build. The things that bothered me were very slight and easily remedied so I would happily buy another kit from Polecat Aerospace. Our first launch here in Montana is in April and I'm eager to fly this rocket.

Flight

Well, I never did get around to reinforcing the avionics bay, but it does not seem to need it. I have flown it twice now and it flies great on a J or a K. It went to 4943 on a K550, and flew straight while doing so. On both flights the shear pins sheared at apogee so I need to either use larger pins (3/32 inch round styrene right now, but may become nylon 4/40 screws soon).

I painted it traditionally, with one yellow and three flourescent red fins.

I flew it again on a Loki Research K-350 moon burner. It went to 7,738 feet.

Other Reviews

- Polecat Aerospace Nike Smoke (5.5\") By Jordan Raice

Brief: This is a nice kit, lightly glassed with pre-cut fin slots. The fiberglass was very easy to sand and prime. Great scale kit!!! Construction: I bought the dual deploy version with a glassed coupler. A small upper payload section, lower BT and a large fiberglass NC. Total length of 76". My cone was a little weak but I added more glass and it is fine now. Great ...

- Polecat Aerospace Nike Smoke (5.5") By Connor Deason

This rocket is a single staged high power rocket. I have flown it on 2 different I motors and it flew both times straight as an arrow. It has a 60" parachute. It was a simple build. This rocket came with a 44 inch long body tube and a 29" fiberglass nosecone. The body tube came pre-glassed, which saved me a lot of work. Also, the fiberglassing was done very professionally. It came with 4 ...

- Polecat Aerospace Nike Smoke (5.5") By

Brief: This is a 1/3 scale replica of the famous sounding rocket from the 1950s and 1960s. You can download their assembly instructions from this page . Construction: It comes with:- 34" long 54mm motor mount two centering rings pre-cut, beveled TTW fins fibreglass nose cone pre-fibreglassed main body tube. but like all the Polecat kits, no ...

|

|

Flights

|

|