| Manufacturer: | Qmodeling  |

Overview

The MRS-WAC Corporal is part of QModeling’s Mega-Retro Series, up-scaled versions of Estes classics built with very high quality components.

Kit Specifications (from the QModeling web site)

- Height: 28.0"

- Weight: 5.8 oz (with recovery system)

- Fin Span Diameter: 6.88"

- Main Body Tube Diameter: 1.637"

- Engines: D or E (Recommended D12-3, E9-4)

- Average Altitudes: 500’ D12-3, 850’ E9-4

About the Company: QModeling is not the typical mom-and-pop hobby rocket company. As their "day job" they do custom engineering services, product design and prototyping, and small-scale manufacturing for industrial customers. About a year ago they entered the upscale model rocket market with their MRS-Vega, an upgrade from the classic Estes Starship Vega, and their product line has now grown to seven models.

With their industrial background, they have the ability to do their own laser cutting and resin casting without relying on outside vendors. Their custom engineering background is obvious in the level of detail in the instruction manuals and the quality of the components. Their laser-cut parts go together like precision machinery.

During construction of this kit, I exchanged over two dozen e-mails with the president, Tom Quinn. Talk about customer service! Tom was very helpful in answering my questions and actively solicited critical feedback to improve the product. He has already changed the manuals based on feedback from me and other customers.

CONSTRUCTION:

This kit was a prize I won in the EMRR Mars Endurance Base writing contest. Within a few hours of sending them the prize request, I received a USPS shipping confirmation notice and a personal e-mail from the president of the company. Two and a half days later, the kit arrived in a triangular USPS Priority Mail carton. The carton was packed quite snugly, but no parts were damaged. The kit was packed in a standard clear plastic bag with hang tag. Subassemblies are packaged inside their own smaller plastic bags, and the hang tag has a check-list that is filled out by QModeling before the kit leaves their factory to ensure quality control.

Chan Stevens has already provided a list of components in his review, so I won’t repeat them.

The instruction manual is 18 pages long, and was obviously written by someone familiar with manufacturing engineering. The text is quite detailed (with occasional humorous notes thrown in) and the illustrations are all professional-grade.

The assembly process is broken down into six major sections, each of which has an estimated completion time listed. I always took WAY more than the estimated time, but then I’m quite nit-picky when I build. If you want to do the sections out of order, the instructions give suggestions on what steps can be done out of order. (For example, shaping the launch conduit can be done while the glue is drying on the engine mount.)

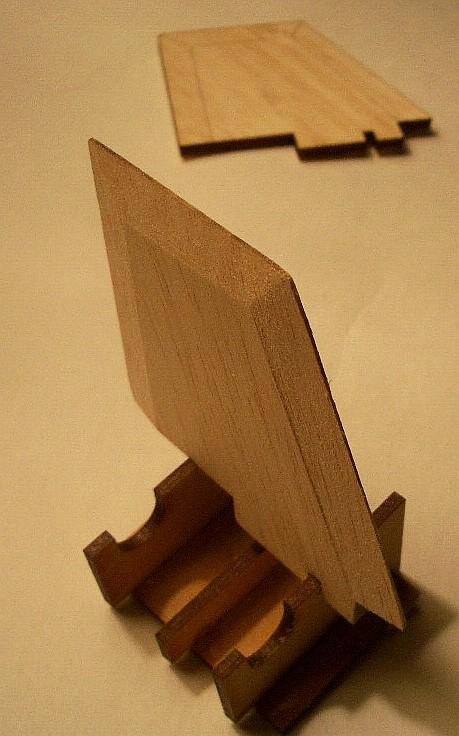

The first section involves building a fin

sanding block assembly from laser-cut parts provided. This is a slick piece of

tooling that enables even a fat-fingered klutz like me to make fin bevels that

are flat, smooth, and consistent. The company’s manufacturing engineering

background clearly shows in the design of this fixture. Not many rocketry

companies would put so much effort on a part that never even leaves the ground.

The first section involves building a fin

sanding block assembly from laser-cut parts provided. This is a slick piece of

tooling that enables even a fat-fingered klutz like me to make fin bevels that

are flat, smooth, and consistent. The company’s manufacturing engineering

background clearly shows in the design of this fixture. Not many rocketry

companies would put so much effort on a part that never even leaves the ground.

Fin preparation is supposed to be the fourth section, but I was so excited by the sanding block assembly that I decided to skip ahead and do the fin shaping right away. The fins are laser-scribed on one side to show the exact edge of the bevel.

The sanding fixture worked great, although it took a lot of time to sand away that much balsa. After spending more than 30 minutes on the first fin, I reached for my Master Airscrew razor plane. This handy little contraption allowed me to quickly shave away the bulk of the wood in a minute or two, and then switch to the sanding fixture for the final shaping. I was able to finish both the second and third fins combined in less time than I spent on the first.

When they are all done, these fins are truly beautiful, with nice crisp edges on the bevels.

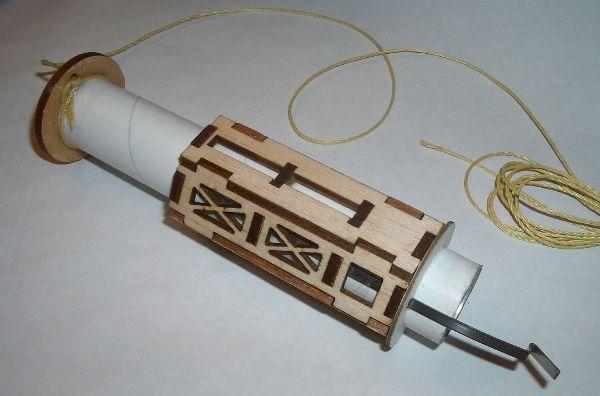

The second section is the engine mount assembly. A QModeling exclusive, the engine mount assembly is laser-cut from thick balsa and goes together like a jig-saw puzzle. Pay attention to the directions, as there are several steps when parts are attached temporarily to align other parts, and it is important that they not be glued into place prematurely. When completed, the assembly provides a very strong mounting and alignment site for the through-the-wall fins, while still remaining fairly light weight.

The thrust ring is positioned to use standard Estes E engines. Shorter 24mm D and C engines can also be used with a spacer that can be built using the provided instructions.

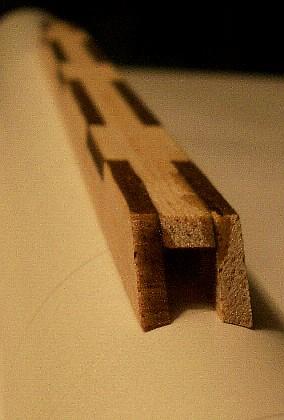

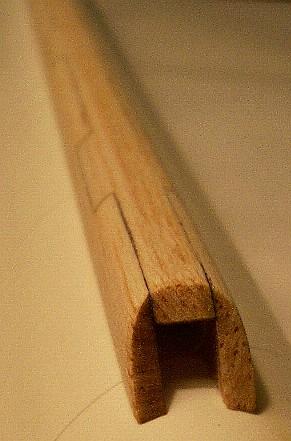

The third section is the launch lug conduit assembly. On the real WAC Corporal, the transfer conduit is aligned with the black fin. The QModeling kit, like the classic Estes kit it is based on, fudges the scale accuracy a bit by offsetting the conduit a little bit away from the fin and then hiding the launch lug inside it. For scale aficionados, the ends of the conduit could be filled with balsa and shaped, while the launch lugs could go on the back side opposite the conduit.

The conduit is built from three pieces of laser-cut balsa that fit together like a jig-saw puzzle. The resulting rectangular conduit then must be shaped into a circular cross-section. The fin-sanding assembly contains a feature that makes it easy to get the correct shape consistently along the length of the conduit. When completed, it is hard to tell that the conduit is actually made from three separate pieces.

The final two sections are Final Assembly and Finishing. Final assembly consists of attaching the fins, filleting the conduit, and attaching the recovery system and nose cone.

The recovery system is darn-near bulletproof, and consists of about 9 feet of Kevlar shock cord, a Nomex Heat Shield, and a really nice 30" Top Flight thin-mill nylon parachute. The 30" chute is standard on all QModeling kits, many of which are quite a bit heavier or more fragile than the WAC Corporal. I think 30" is too big for a 6 oz rocket with TTW fins like this, and that 18" would be a more appropriate size. Tom and I had much discussion about the size of this chute, and he finally convinced me to try the 30" chute with a knot in the shroud lines to keep it from fully inflating.

The nose cone is made of a heavy cast resin. It had almost no seam lines, but the surface had many tiny voids due to bubbles in the resin. Four layers of primer and a bunch of wet-sanding took care of them nicely. A single coat of Rustoleum Painter’s Choice Gloss Black left a nice smooth finish.

For the fins, I applied a thin coat of Fill-n-Finish, sanded smooth with #320 grit. Next, five coats of alternating white and gray primer with lots of sanding in between. I could have saved two or three coats of primer if my wedding ring hadn’t dug into two of the fins while I was sanding them.

The final finish on one fin was a coat of Rustoleum Painter’s Choice Flat Black, followed by a coat of Rustoleum Painter’s Choice Gloss Black. The other two fins had three coats of Rustoleum Silver Metallic. I should have used plain silver, but I was out of it and didn’t realize how sparkly the metallic paint would be. It looks nice, just not historically accurate. Two coats of Future acrylic floor polish really bring out the depth and luster of the metallic paint.

For the body tube spirals, I used four coats of Rustoleum Painter’s Choice sandable primer, alternating between white and gray with each layer, and sanding most of the primer off between coats. It probably would have been faster to use Elmer’s Fill-n-Finish first , but the spirals were quite small so I thought I’d try using just primer this time.

The body was finished with a single coat of Rustoleum Painter’s Choice Gloss White. After masking off the lower body and two stripes, a single coat of Gloss Black was the final painting step.

At last I attached the fins to the body using 5-minute epoxy. They fit beautifully into the slots in the jig-saw engine mount.

My final finishing step was to apply fillets of 30-minute epoxy. By rights, the painting should all be done after the fins are attached and filleted so the epoxy can penetrate the fins and the body for added strength. By applying the fillets after the paint I am sacrificing a lot of strength, but still getting the aerodynamic and appearance benefits. On a kit of this size, the strength isn’t critical, but I don’t recommend this technique on big birds where bond strength is essential.

No decals are provided on this kit. The Estes classic kit had no decals, and the full-scale WACC had very few markings, so the decals aren’t really missed.

Overall, this kit was an absolute pleasure to build. The sanding fixture and the jig-saw engine mount really add a unique flavor to the build process and yield outstanding results.

Construction Rating: 5 out of 5

FLIGHT/RECOVERY:

QModeling recommends the D12-3 and E9-4 engines for this kit and predicts altitudes of 500 and 850 feet respectively. My RockSim model shows that this kit has better performance than these guys are letting on, and it should be able to also use a C11-3, D12-5, E9-6, or even an F21-8.

The recommended engines are good choices for angled flights or if there is much wind. When flying straight up on a calm day, it should be possible to use the next-longer delay.

| RockSim Altitude Predictions |

||

|

|

Max Alt |

Opt Delay |

| C11-3 |

238 |

3.26 |

| D12-3* |

539 |

3.45 |

| D12-5 |

597 |

4.95 |

| E9-4* |

1269 |

4.47 |

| E9-6 |

1363 |

6.31 |

| F21W-6 |

2236 |

6.48 |

| F21W-8 |

2294 |

7.98 |

*= Recommended by Manufacturer

Pre-flight preparation instructions seem pretty easy (yet I still managed to screw it up the first time).

- Tuck most of Kevlar shock cord into body tube.

- Insert Nomex Heat Shield.

- Fold and insert parachute.

- Tuck rest of shock cord into body tube.

- Attach nose cone.

- Insert engine and igniter.

The Heat Shield eliminates the need for wadding when used properly.

On the day of the maiden flight, the day started with brisk winds and intermittent rains. By the end of the launch session, the rain had stopped but the wind was still higher than I would have liked. I decided to knot the shroud lines about 8 inches from the swivel to keep the chute from inflating too far, angle the rod 20 degrees into the wind, and cross my fingers. With the strong horizontal flight component lowering the apogee, I decided to use the shorter delay of a D12-3 instead of the D12-5 that RockSim recommended for straight vertical flights.

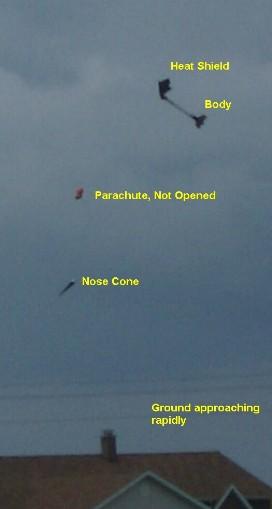

Takeoff was nice and straight, arcing over near apogee,

then POP the recovery system spewed out. After several seconds of falling,

still no chute. It landed hard, snapping off one of the silver fins. When I got

to the crash site I found that the shroud lines were still tightly wrapped

around the chute which never unfurled. I also discovered some scorch marks

where hot gas had gotten around the Heat Shield. The scorches did not

contribute to the hard landing, but they still concerned me.

Takeoff was nice and straight, arcing over near apogee,

then POP the recovery system spewed out. After several seconds of falling,

still no chute. It landed hard, snapping off one of the silver fins. When I got

to the crash site I found that the shroud lines were still tightly wrapped

around the chute which never unfurled. I also discovered some scorch marks

where hot gas had gotten around the Heat Shield. The scorches did not

contribute to the hard landing, but they still concerned me.

Upon re-reading the directions, it appeared I had done everything as directed. Why hadn’t it worked?

After sending crash photos to QModeling, Tom Quinn sent me back fold-by-fold directions on the best way to pack the chute. The new way involved wrapping the shroud lines around the chute lengthwise instead of wrapping them around the circumference. This looks like a bulkier package but it easily unrolls under its own weight. Then instead of packing the chute on top of the Heat Shield where it can be damaged by any hot gas that leaks past, the Heat Shield is tightly wrapped around the chute and shrouds. The first time I tried folding with this method, I couldn’t even get the bundle to fit into the tube, but after a few tries I was able to wrap a nice tight package that easily slid in and out. I hope they update the instructions with this packing technique because it works great.

I re-attached the broken fin and applied an extra-generous epoxy fillet. A week later I was ready to attempt a second flight. The wind was much calmer, so I decided to shoot straight up and use the longer delay D12-5.

Once again the boost was nice and straight with a gentle arc-over at apogee. Ejection occurred at least a second past apogee and this time the chute inflated perfectly. Descent was agonizingly slow even with the shrouds shortened by 8 inches. The modeled drifted to a gentle landing near the south edge of my field.

I decided to press my luck and move up to an E9-4. To counteract the drift I shortened the shroud lines another two inches and angled the launcher about 10 degrees upwind and to the north. This time the boost was long and slow into the wind with another perfect deployment. It drifted for a long time and finally landed near the far eastern edge of the field, about 15 feet from the blacktop. The shroud line got a little tangled in the long Kevlar shock cord. Good thing, too, or it might have drifted even further.

I plan to order a smaller nylon chute for this, either an 18" octagon or a 24" cross-form, to cut down on the drift.

- Flight Rating: 5 out of 5

- Recovery Rating: 3½ out of 5

OVERALL:

A really solid model backed up by a great company. Barring a complete screw-up with the parachute (like I had on my first flight), this kit should hold up well to repeated flights. I am really looking forward to future QModeling releases.

PROS:

- Sanding fixture for consistently good bevels.

- Should be very durable with its foil-lined engine tube, Nomex Heat Shield, Kevlar shock cord, Nylon parachute, and TTW fins.

- Jig-saw engine mount assembly is strong and precise without weight penalty.

- Detailed instructions.

- Outstanding customer support.

CONS:

- I still think the 30" parachute is too large for this kit.

Overall Rating: 5 out of 5

Other Reviews

- Qmodeling WACC By Fred Talasco

(by Fred Talasco - 06/10/04) Brief: Mid power scale model upscaled from the Estes WAC Corporal. Construction: The model is based on the BT-60 and has a 24mm 'E' length engine mount which makes the kit over 28 inches tall. The nose cone is injection molded of a soft plastic with a laser cut wooden plug that also serves as a screw eye mount. The fins, TTW fin mount braces, and fuel ...

- Qmodeling WACC By Chan Stevens

Brief: Relatively tiny for the "Mega" line of Estes upscales, this WAC is a fine looking scale kit and great flyer. An excellent kit in every way even though at $50 list, scale builders on a budget might consider the ASP 24mm version (listing for $20). Construction: I ordered this kit online (actually won it on eBay) and the kit arrived Priority Mail 3 days later. ...

|

|

Flights

|

|

B.C. (February 2, 2005)

B.C. (August 3, 2005)

J.H. (June 13, 2006)

|

|

A.H. (January 30, 2005)